Electric-control pneumatic battery changing system and method for electric truck and load-carrying electric vehicle

An electric system and electronic control technology, which is applied in electric vehicles, charging stations, vehicle energy storage, etc., can solve the problems of long parking time, low efficiency of vehicle inspection, poor reliability and safety, etc., and reduce the power supply The effect of improving battery replacement efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

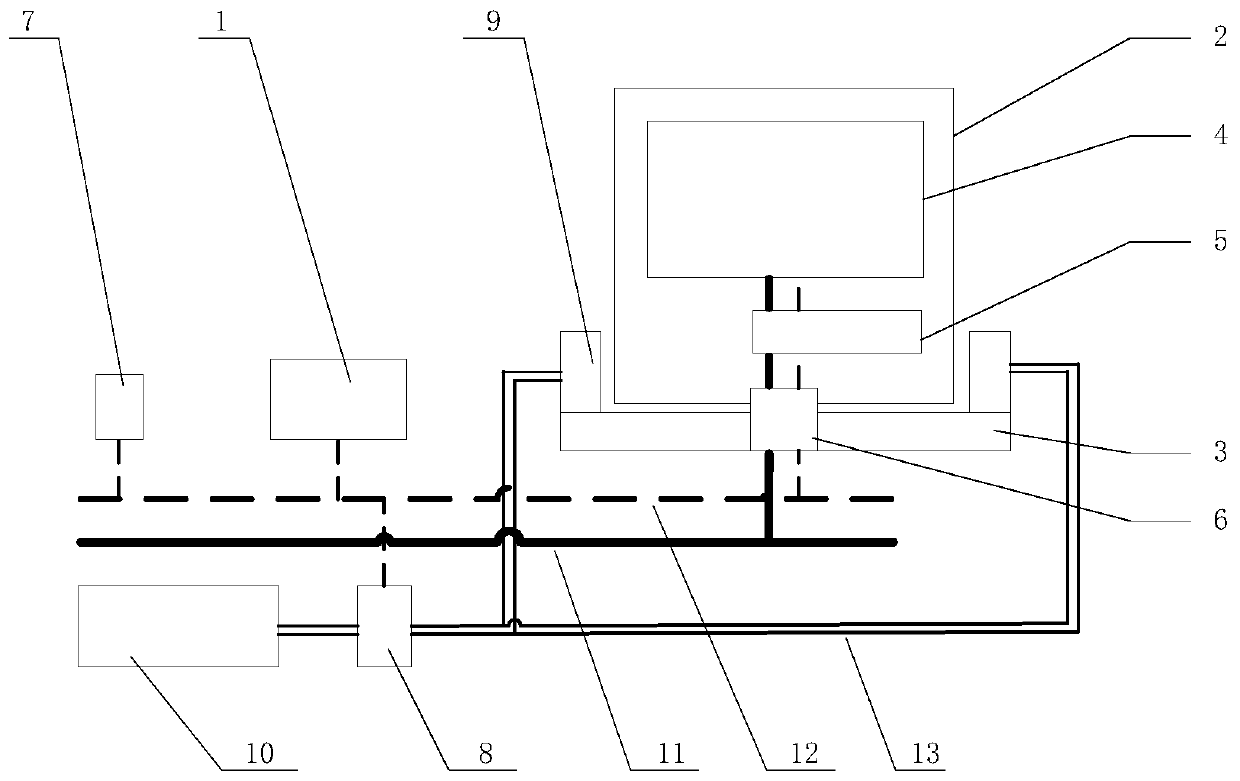

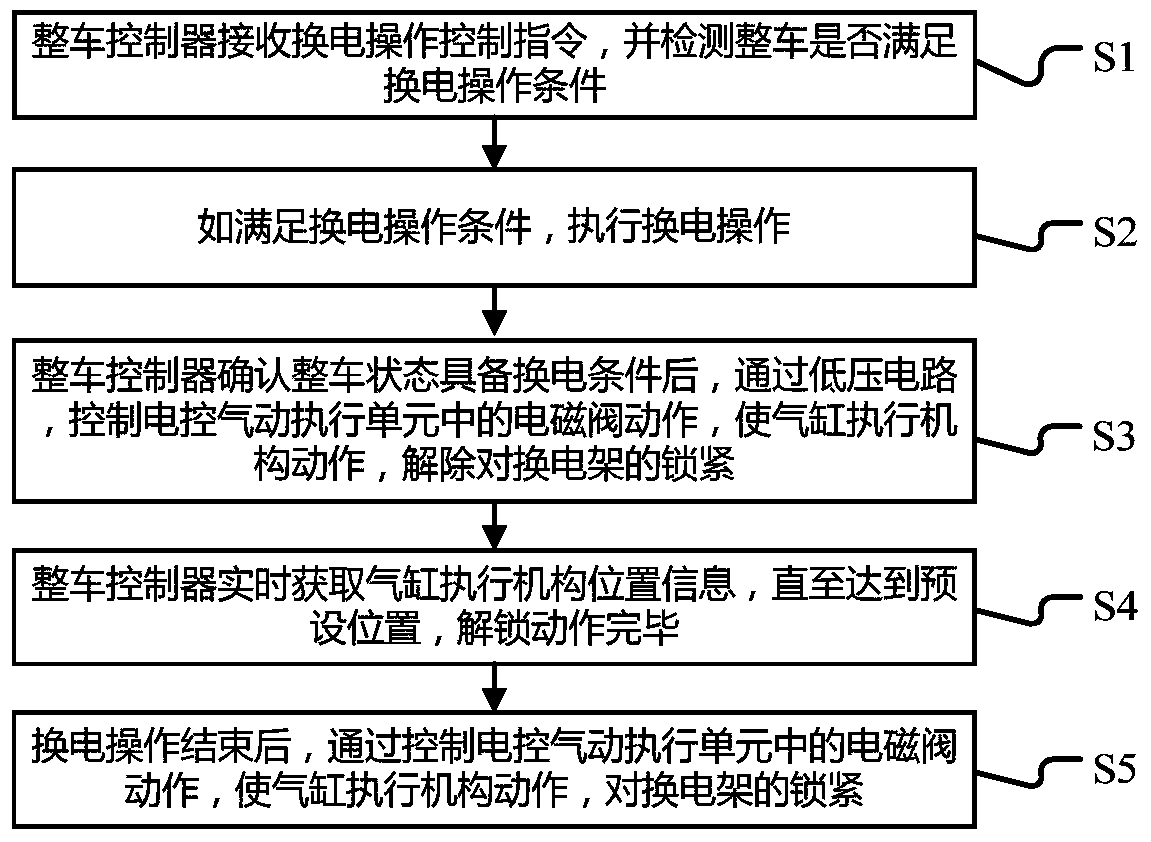

[0073] As a specific embodiment of the present invention, it includes: the power battery pack 4 and the battery manager 5 are assembled in the power exchange rack 2, the vehicle-mounted battery exchange stand 3 is used to carry the power exchange rack 2, and the power exchange rack 2 is connected with the high-voltage circuit of the whole vehicle 11. The connection between the low voltage circuit and the CAN communication network 12 is realized through the high and low voltage electrical socket 6 . The electro-pneumatic actuator unit includes a power exchange control switch 7 , a solenoid valve 8 , a cylinder actuator 9 , an air reservoir 10 and an air circuit 13 . The vehicle controller 1 is used to receive driver control signals, parking signals, KEY ON signals, battery manager handshake signals, power battery main contactor status signals, etc., to identify driver intentions, and to realize Control and monitoring of the whole vehicle battery replacement system.

[0074] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com