Explosive ordnance disposal and portable water cutting treatment device

A processing device and portable technology, applied in the direction of metal processing, etc., can solve the problems of easily damaged internal components of the machine, inconvenient movement and handling, waste of water and raw materials, etc., to protect normal work, improve service life, and work range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

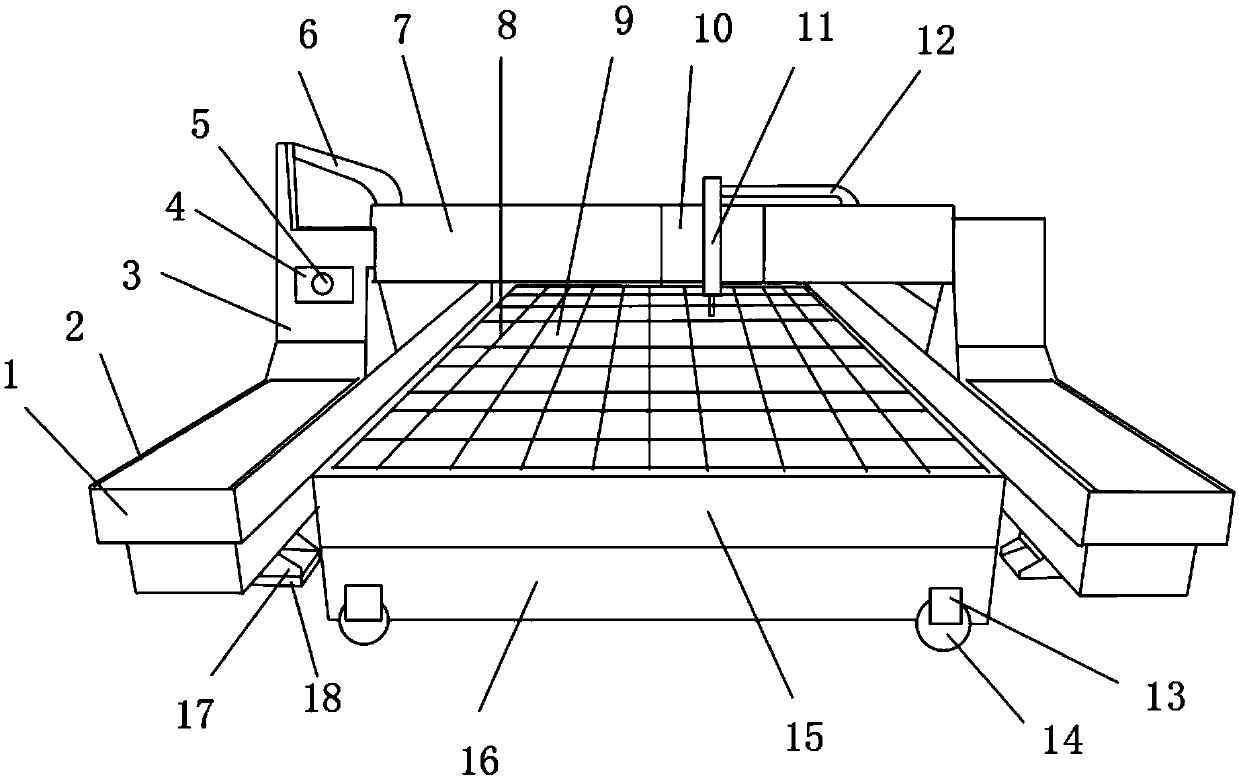

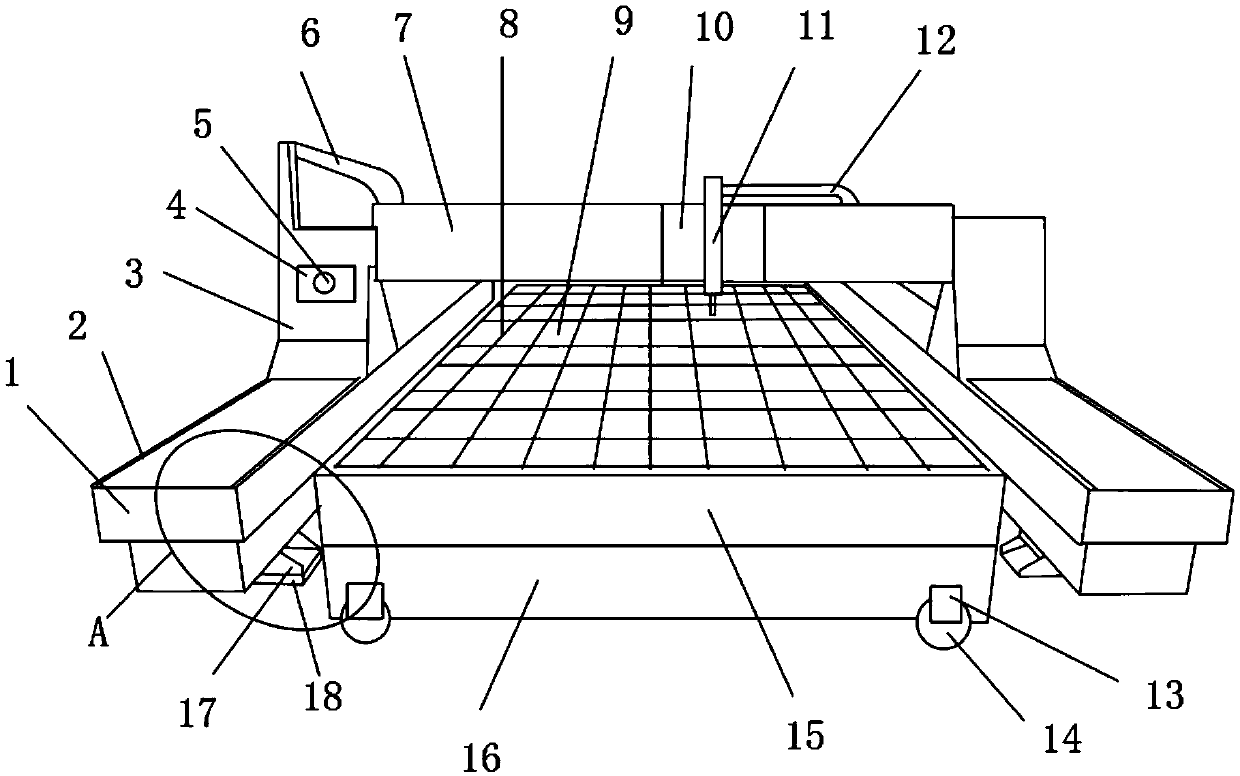

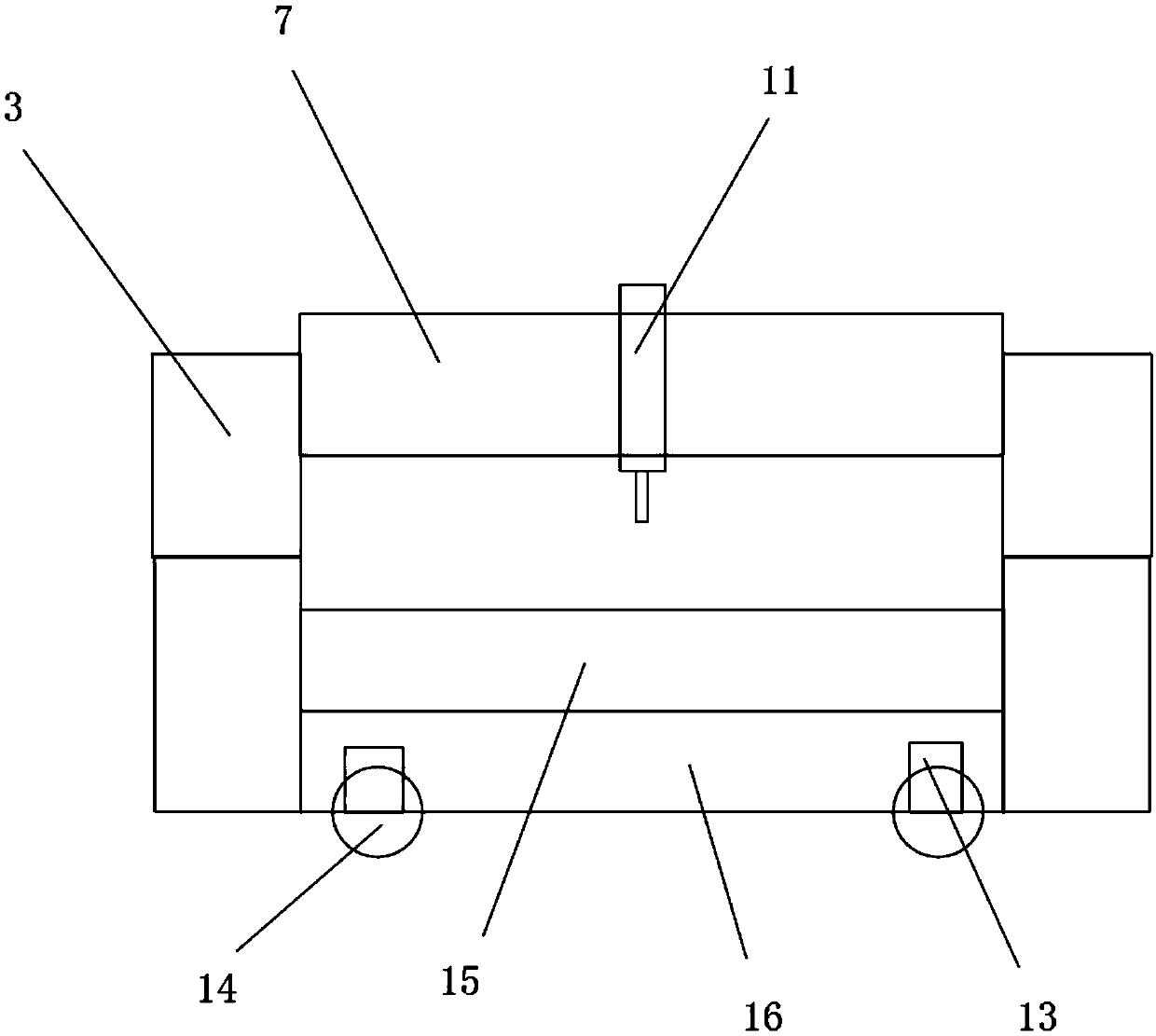

[0018] Such as Figure 1-4 As shown, a portable water cutting treatment device with explosive discharge includes a platform 1, a No. 1 transmission belt 6, a connecting shaft 13, and a baffle 15. The upper end of the platform 1 is provided with a sliding track 2 and a body 3, and the body 3 The sliding rail 2 and the platform 1 are fixedly connected, a control board 4 is provided on one side of the body 3, and a control button 5 is provided on the outer surface of the control board 4, and a frame 7 is provided at one end of the No. 1 transmission belt 6, One side of the frame 7 is provided with a slider 10, the outer surface of the slider 10 is provided with a cutting head 11, and one side of the cutting head 11 is provided with a No. 2 transmission belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com