Drilling and hair-planting technology and device of white leather strip and rubber silk with one hole and two plants

A white leather strip and hair planting technology, applied in brushes, household appliances, brush bodies, etc., can solve the problems of inability to achieve the use effect, glass damage, low efficiency, etc., and achieve high drilling efficiency, prolong service life, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The glass brush handle of this embodiment is set as: every hole planting pores synchronously plant one white leather strip 1.11, twenty glue strips 2.11;

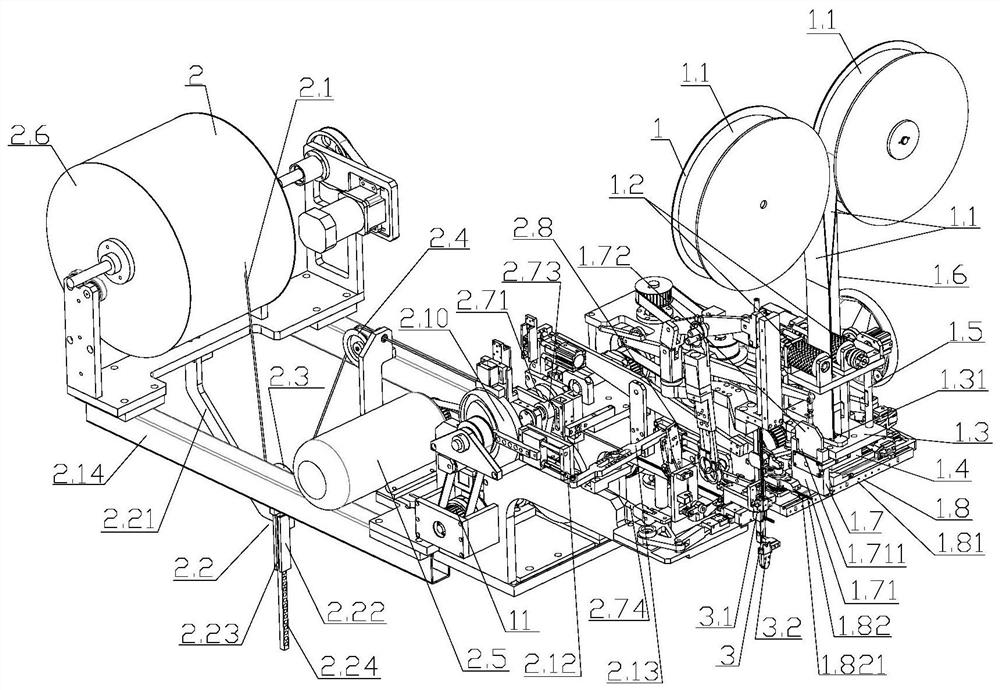

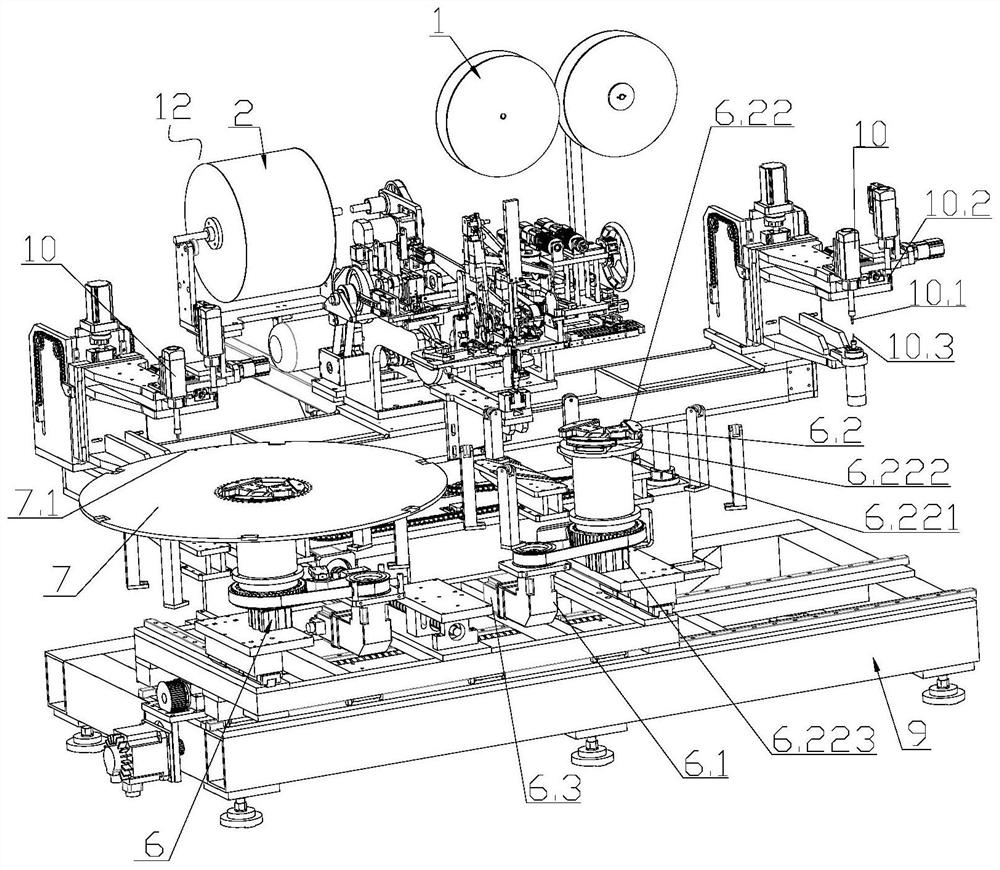

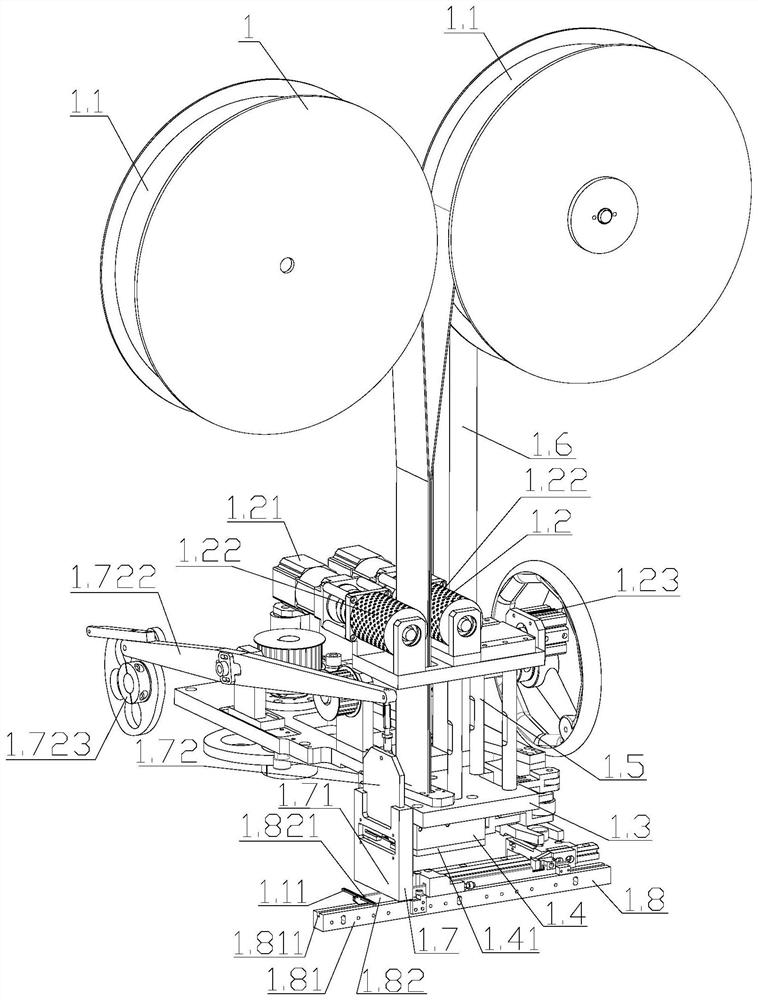

[0084] Such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 9 , Figure 10 , Figure 15 , Figure 20 , Figure 22 , Figure 24 As shown, the white leather strip and glue silk one hole two planting drilling hair planting process, specifically include the following steps:

[0085] Step 1: Install the brush handle,

[0086] Install the two brush handles 7 on the two fixture panels 6.221 respectively, adjust the locking cylinder 6.223 to control the brush handle locking machine device 6.222 to lock the brush handles 7 on the fixture panels 6.221; the workbench 6 moves laterally to drive one of them The brush handle 7 moves to the bottom of the first drilling mechanism 10, and the other brush handle 7 moves to the bottom of the hair planting mechanism 3;

[0087] Step 2: Drill the hole, ...

Embodiment 2

[0161] With embodiment 1, the difference is that: the glass brush handle of this embodiment is set as: two 1.11 white skin strips and 2.11 twenty glue strips are synchronously planted in each hole.

Embodiment 3

[0163] Same as Example 1, the difference is: the glass brush handle of this embodiment is set as follows: 1.11 pieces of white leather strips are synchronously planted in each hole, and 20 glue strips 2.11; the P wool strips 2.11 are located in the inner core, and the white leather strips 1.11 is located at the periphery of the rubber strip 2.11; during synchronous hair planting, the glue strip 2.11 is located above the white leather strip 1.11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com