Method for measuring disintegration of fibrous product

A technology for measuring fibers and fiber products, which is applied in the field of fiber products, can solve the problems of clogging sewage systems and discharge clarifiers, measuring or verifying few fiber products, no information, etc., to achieve improved evaluation and understanding, reliable disintegration ability, The effect of reducing operational failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] equipment

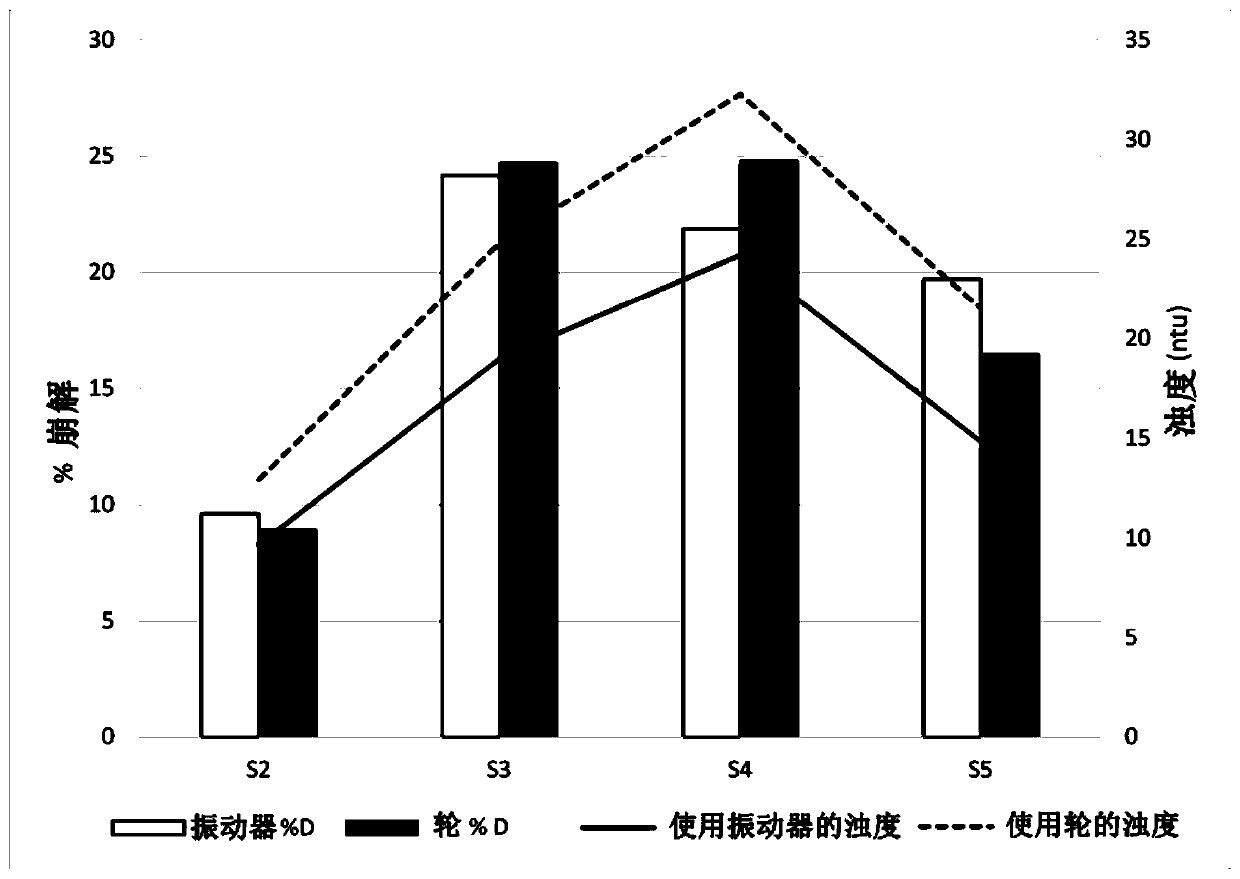

[0109] ·Horizontal mixing wheel

[0110] ·Programmable orbit vibrator

[0111] ·200ml glass bottle

[0112] ·Analytical balance with an accuracy of 0.001g

[0113] ·Laboratory oven, heated to 105°C

[0114] ·Aluminum weighing pan

[0115] · Cutting table or scissors

[0116] · Dynamic Drain Tank (digital output preferred), DDJ, with coarse back-up screen with mesh size approximately 1 / 16"

[0117] · Collection container

[0118] 4L vacuum bottle with 150mm diameter Buchner funnel

[0119] Whatman#4 qualitative filter paper, diameter 150mm, Cat.No.1004150

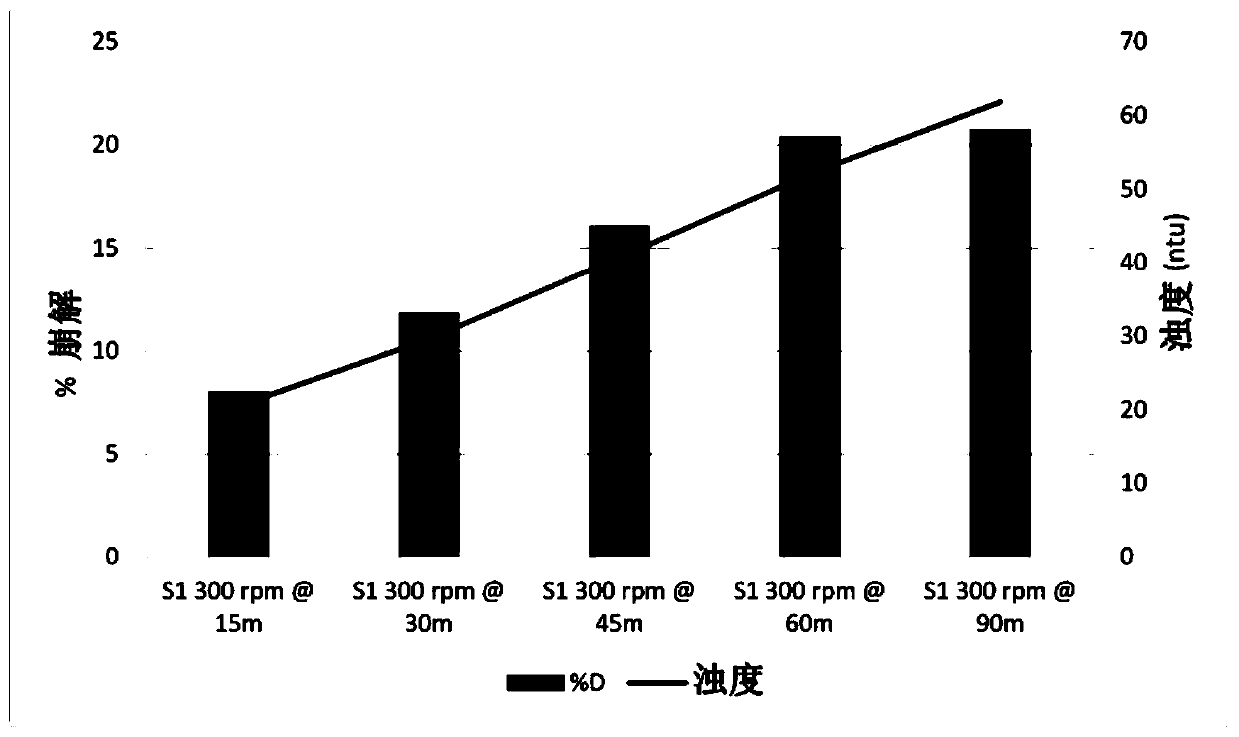

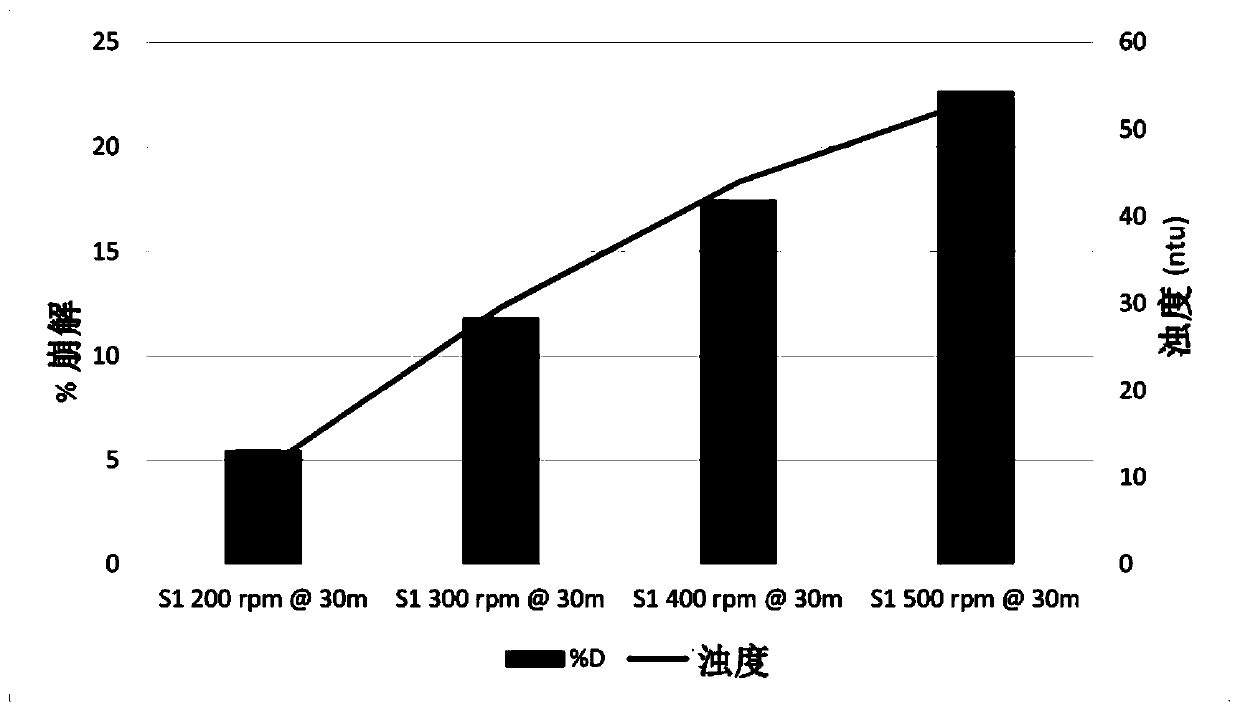

[0120]• Hach 2100P Turbidimeter, Model 2100P. The model operates on the Turbidity method principle of turbidity measurement. The optical system includes a tungsten lamp, a 90° detector to monitor the scattered light, and a transmitted light detector. The instrument's microprocessor calculates the ratio of the signals from the 90° detector and the transmitted light detector. This ratio techniq...

Embodiment 2

[0154] equipment

[0155] ·Horizontal to vertical adjustable wheel mixer set at 45 degree angle

[0156] · (4) 200ml glass bottle with cap, (8) when free fibers and fine fibers are also quantified

[0157] ·Analytical balance with an accuracy of 0.001g

[0158] ·Laboratory oven, heated to 105°C

[0159] ·Aluminum weighing pan

[0160] · Cutting table or scissors

[0161] ·Dynamic Drain Jar (DDJ also known as Britt Jar), 3 / 8" inside with standard drain plug plug

[0162] Internal Diameter Drain Modification. The DDJ impeller itself can be used when required. A 4.125" diameter DDJ screen with 1 / 2" diameter perforations and 11 / 16" offset. Optionally, a 1 / 16" diameter perforated screen with 7 / 64" offset for free fiber and fines quantification.

[0163] ·4L collection beaker

[0164] 4L vacuum bottle with 150mm diameter Buchner funnel

[0165] Whatman#4 qualitative filter paper, diameter 150mm, Cat.No.1004150

[0166] 250ml and 1000ml graduated cylinders

[0167] ·1L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com