Highly-integrated on-board driving wall washer

An integrated, wall washer technology, applied in electrical components and other directions, can solve the problems of complex production process, low production efficiency, high lighting cost, short production cycle, simple assembly, and improve market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings and embodiments.

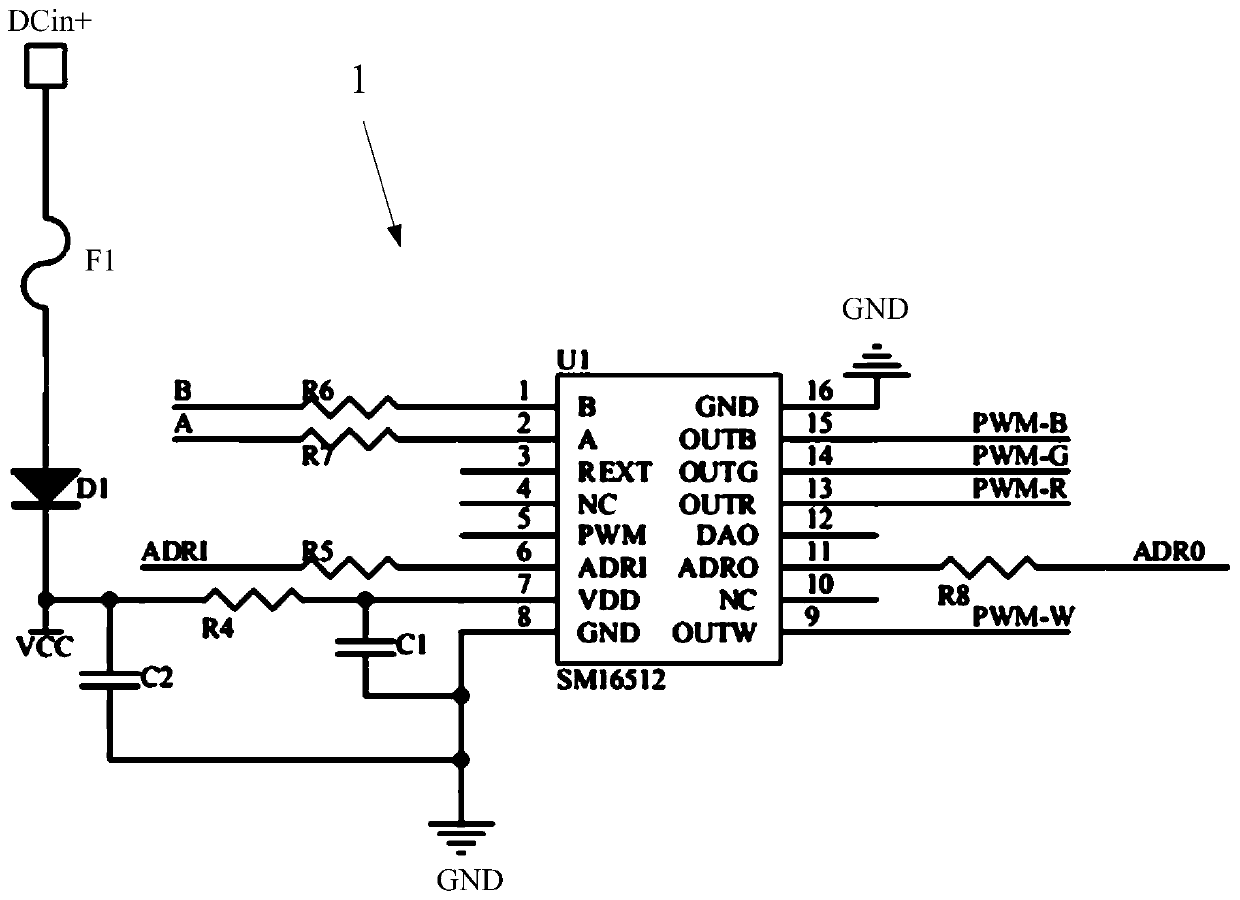

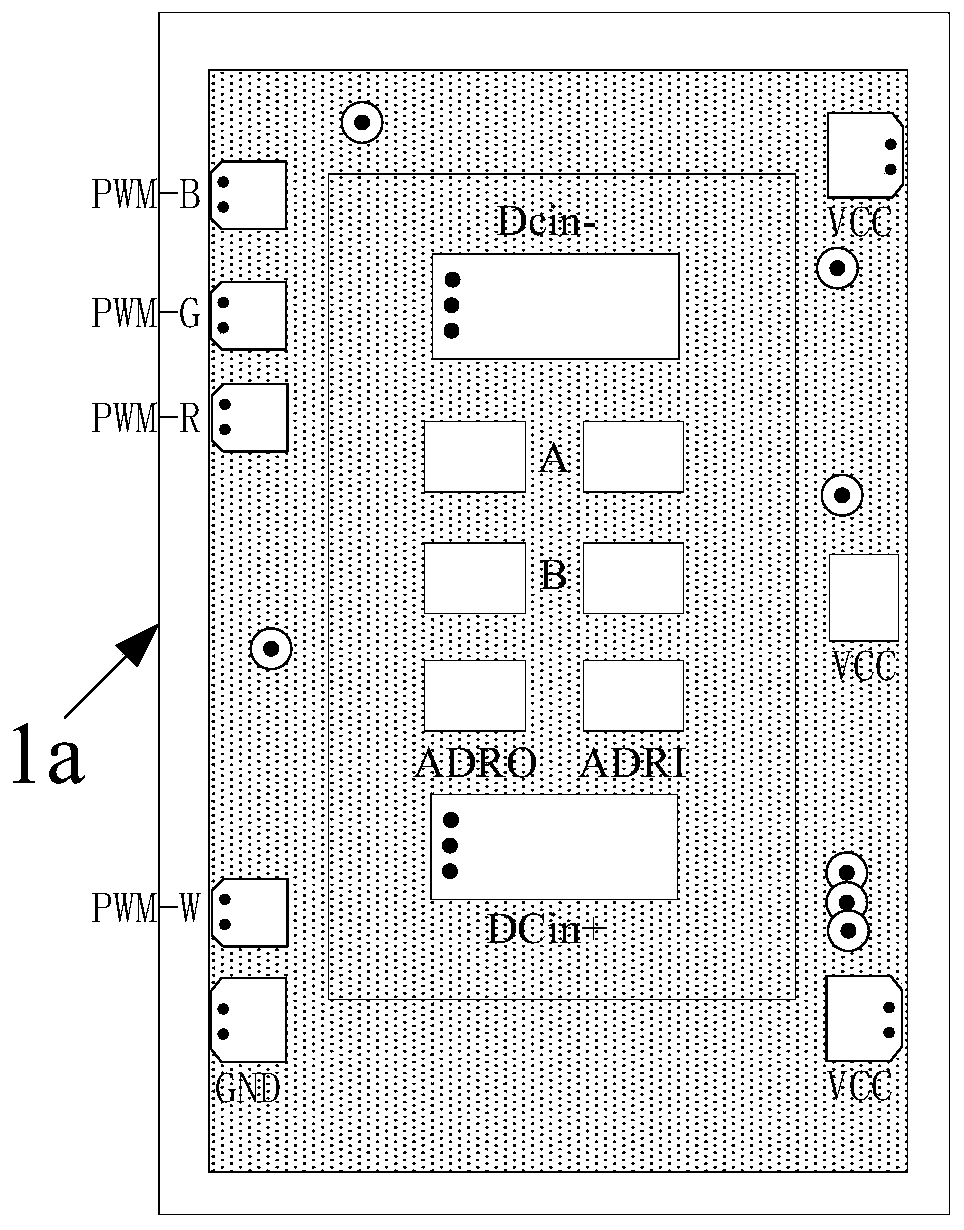

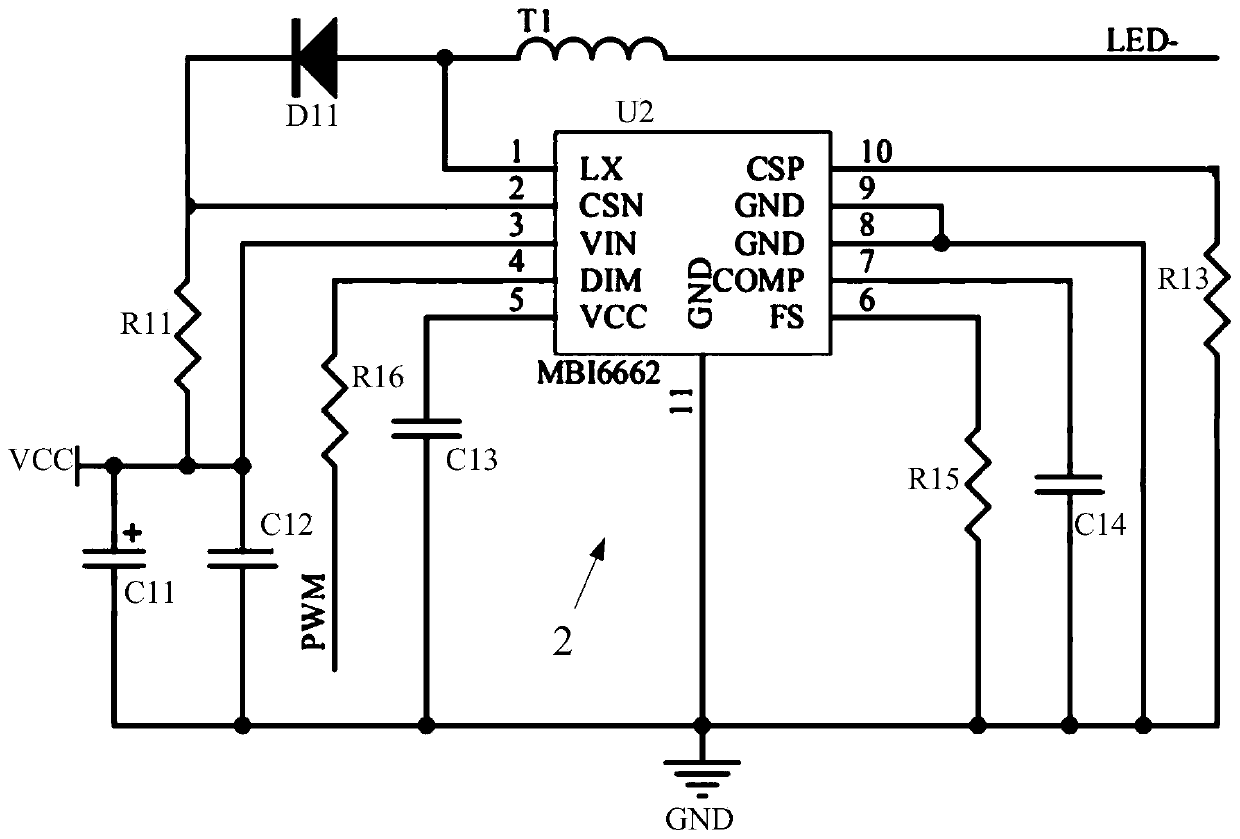

[0034] An embodiment of the present invention proposes a highly integrated board-driven wall washer, including a control module 1, a DC-DC constant current drive module 2, an LED light source module 3, and a heat dissipation lamp body 4;

[0035] Among them, the control module 1 adopts DMX512 control module; DMX512 is a standard for digital signal control lighting equipment;

[0036] Wherein, the LED light source module 3 includes an LED substrate 301 and an LED light string installed on the LED substrate 301; the LED substrate 301 is embedded in the front of the heat dissipation lamp body 4; the LED substrate 301 can be an aluminum substrate, and its front and back are provided with insulating paint (except pad position);

[0037] The heat dissipation lamp body 4 is made of aluminum profile;

[0038] The length of a wall washer is about 1 meter, so the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com