Rapid braking control system and control method for three-phase switched reluctance motor

A reluctance motor, three-phase switch technology, used in control systems, AC motor control, electrical components, etc., can solve the problems of inability to achieve frequent braking, inability to meet use requirements, low braking efficiency, etc., and achieve high reliability. , High space utilization, and the effect of improving braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

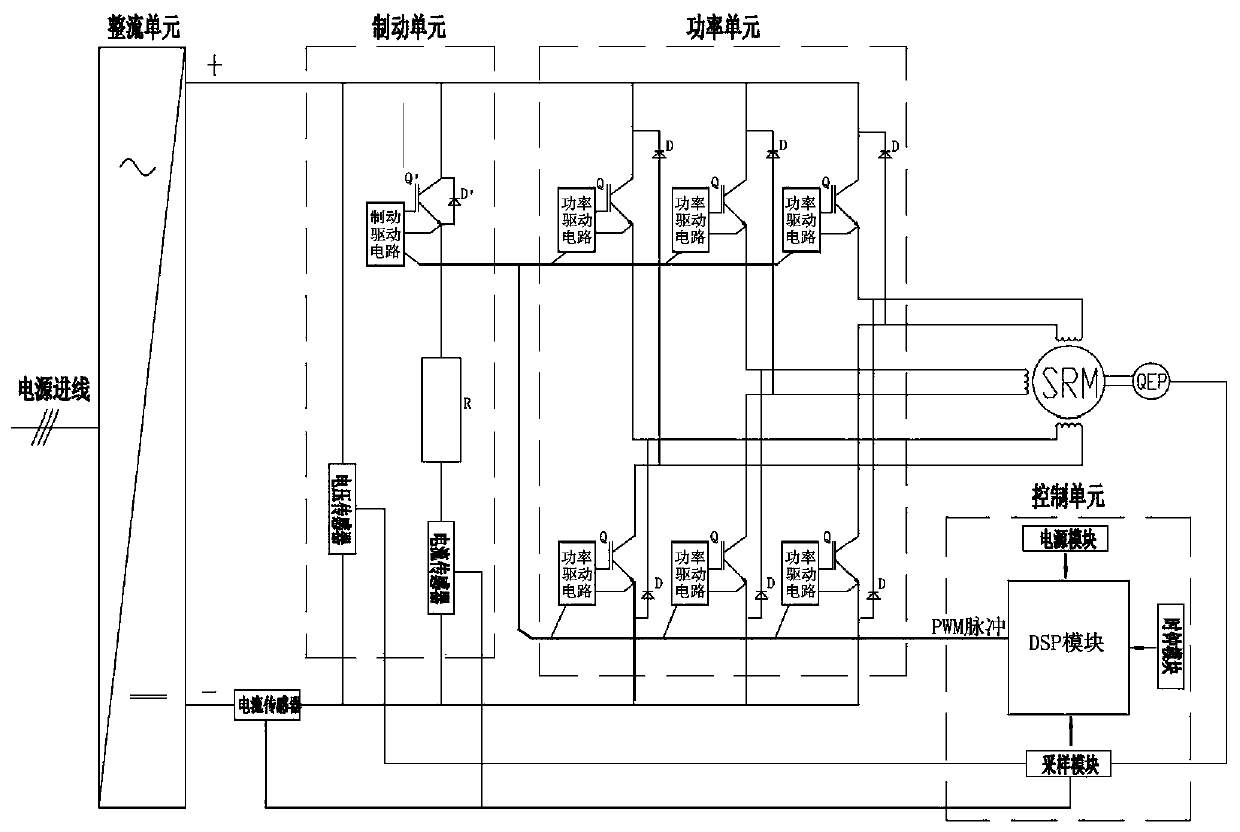

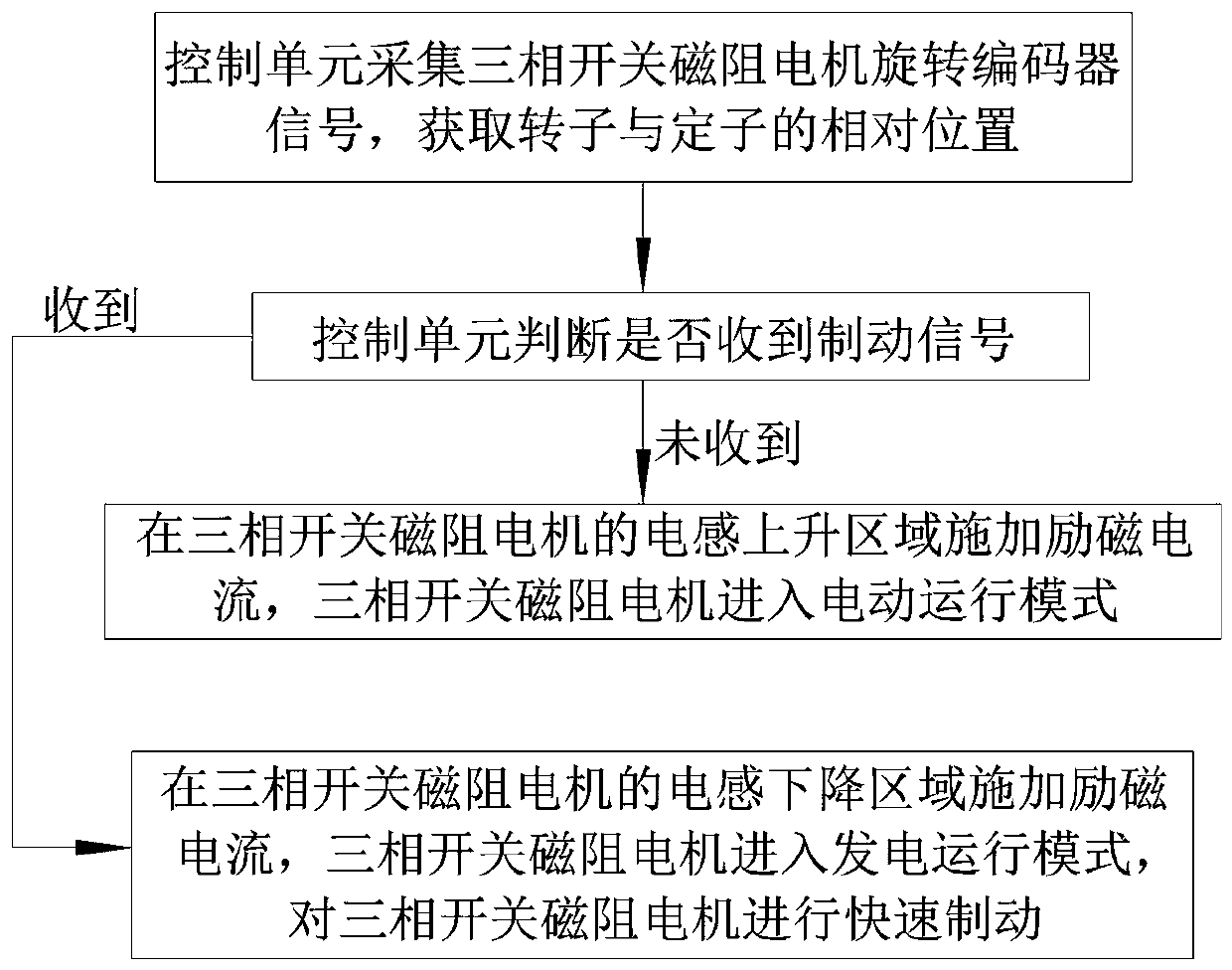

[0041] Such as figure 1 As shown, the present invention includes a fast braking control system and braking method for a three-phase switched reluctance motor.

[0042] The brake control system includes a rectifier unit, a power conversion unit, a control unit and a brake unit. The rectifier unit provides the power current required by the control system through the DC bus;

[0043] The rectifier unit is respectively connected to the three-phase coils of the three-phase switched reluctance motor through the power conversion unit;

[0044] The power conversion unit includes three asymmetrical half-bridge power circuits, and the three-way asymmetrical half-bridge power circuits are connected to the three-phase coils of the three-phase switched reluctance motor in one-to-one correspondence;

[0045] The braking unit includes a braking IGBT module and a braking resistor. The braking IGBT module is connected in series with the braking resistor and connected to both ends of the rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com