Rotor of self-starting permanent magnet synchronous motor

A permanent magnet synchronous and motor technology, which is applied to synchronous machine parts, electric components, magnetic circuits, etc., can solve the problems of low utilization rate of permanent magnet materials, excessive quantity and wide width, and weakened mechanical strength of punching sheets. Achieve the effect of improving ventilation effect, low manufacturing cost and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

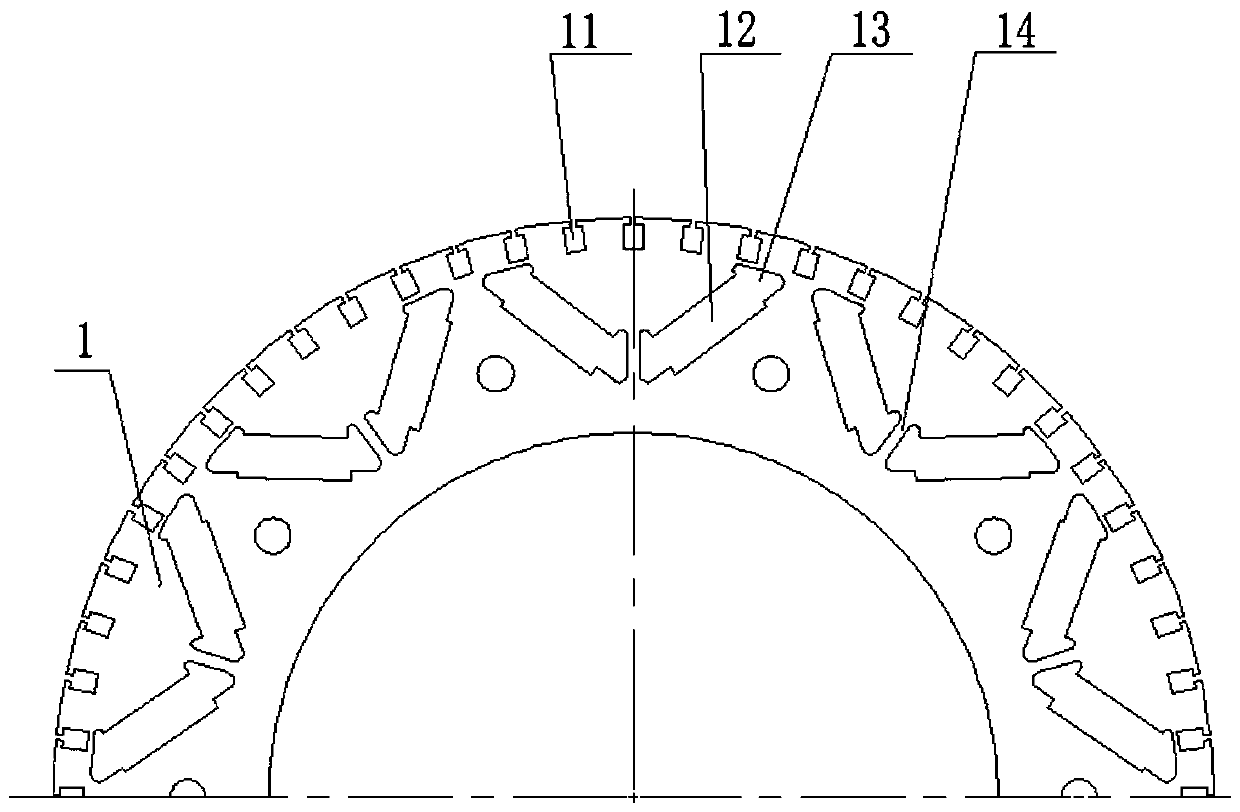

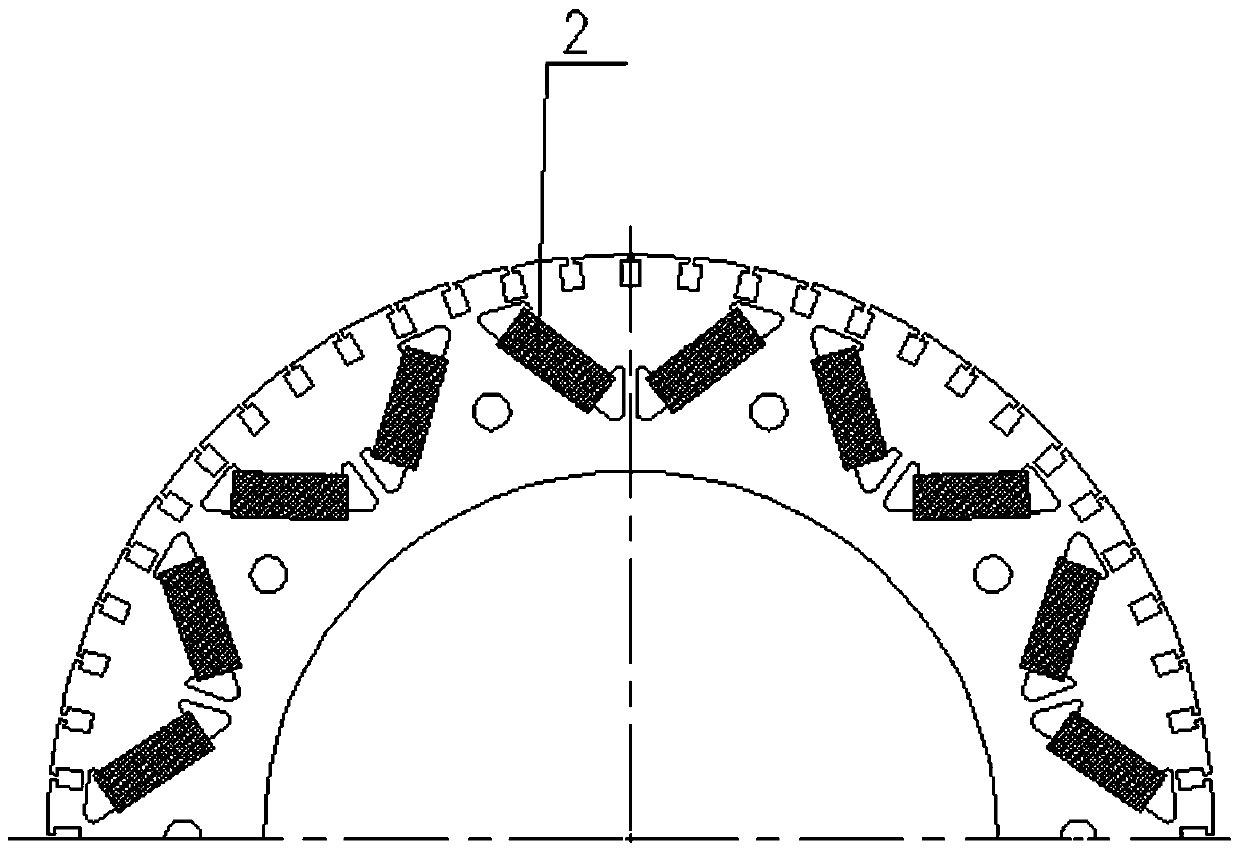

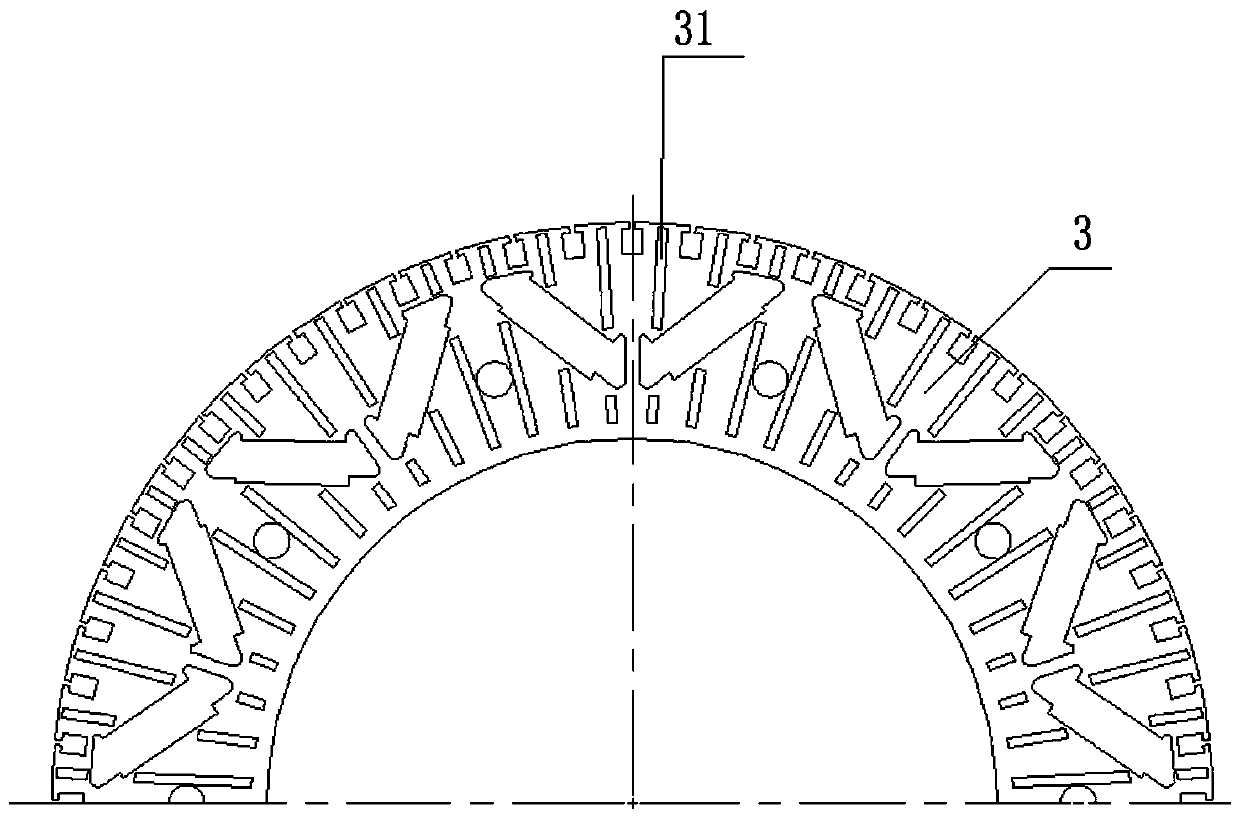

[0023] like Figure 1-Figure 5 As shown, the present invention provides a self-starting permanent magnet synchronous motor rotor structure, which is specifically applied to a multi-pole high-voltage high-efficiency self-starting permanent magnet synchronous motor. Plate 4, ventilation groove plate 3, damping strip 5, end ring 6 and inner fan 7; among them, rotor punch 1 adopts figure 1 structure, the rotor punch 1 is provided with a plurality of V-shaped grooves around the circumference, in order to prevent the closed magnetic field from being formed at the sharp corners of the V-shaped grooves, two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com