Manufacturing method of lithium ion battery

A technology of lithium-ion batteries and manufacturing methods, which is applied in the direction of electrolyte storage battery manufacturing, secondary batteries, battery pack parts, etc., can solve the problems of long lithium-ion battery preparation cycle, affecting the preparation cycle, and waste of aluminum-plastic films, etc. The effect of shortening the baking time, reducing the two-sealing process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

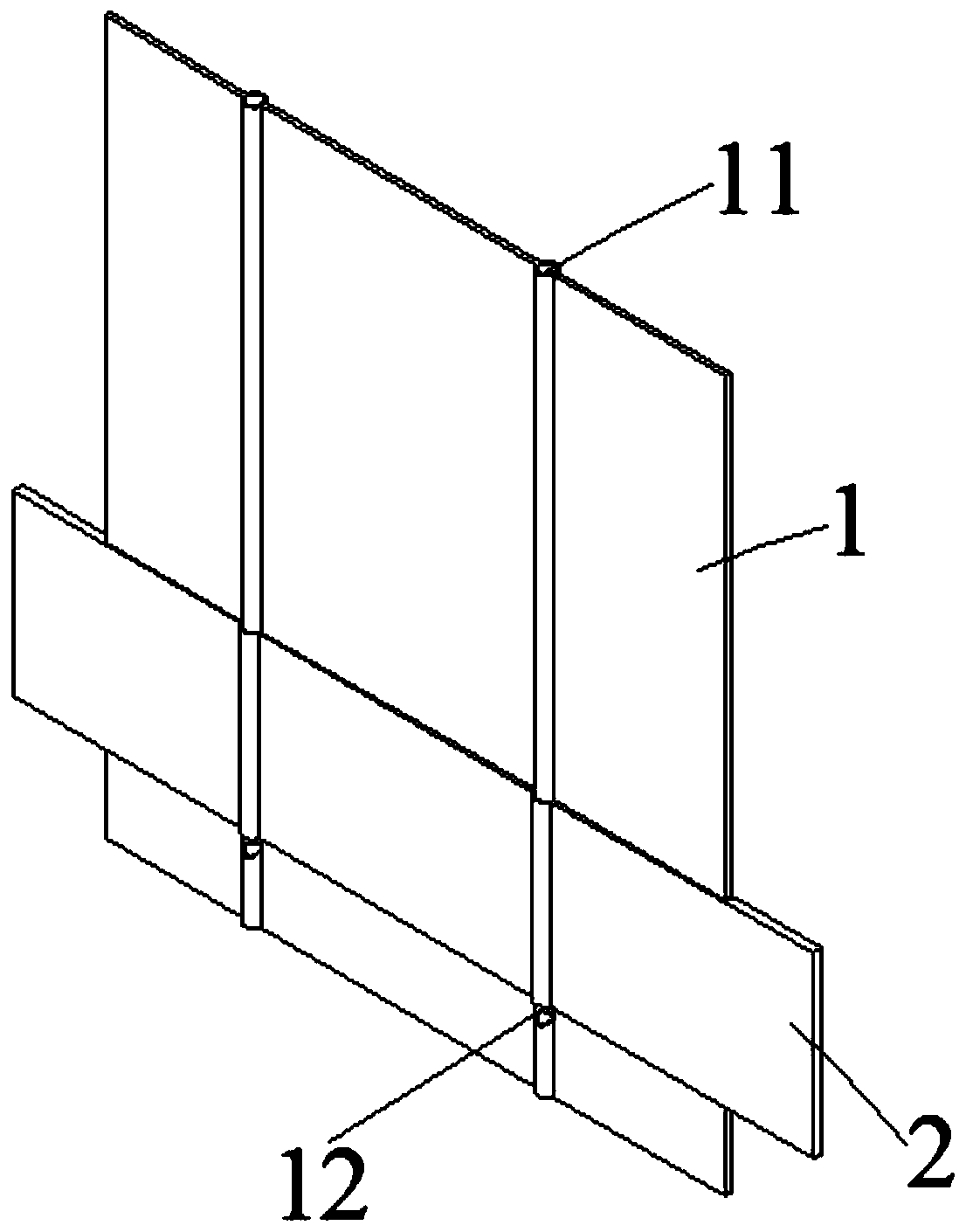

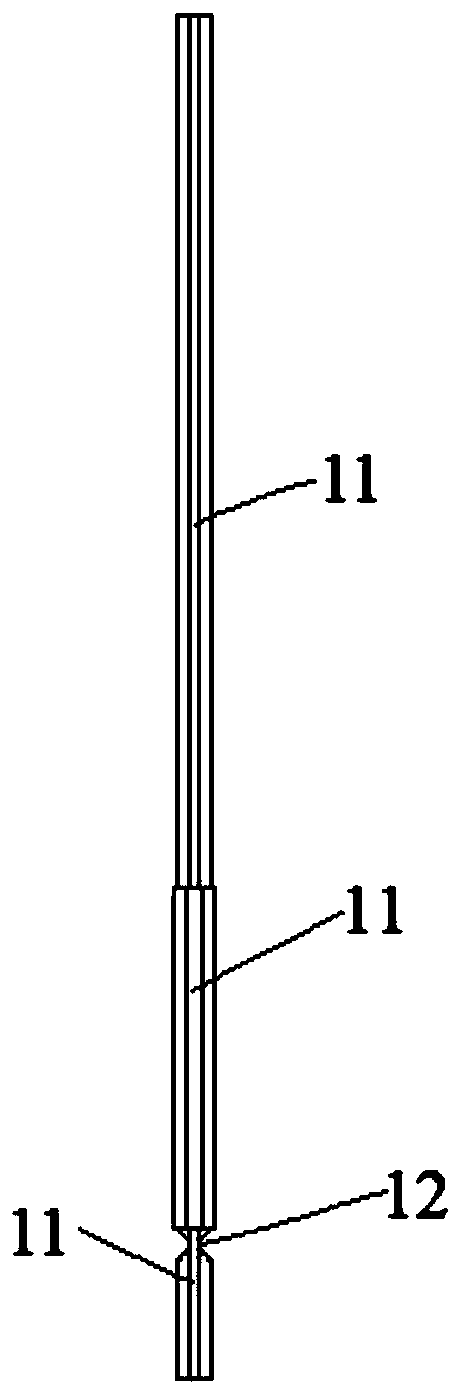

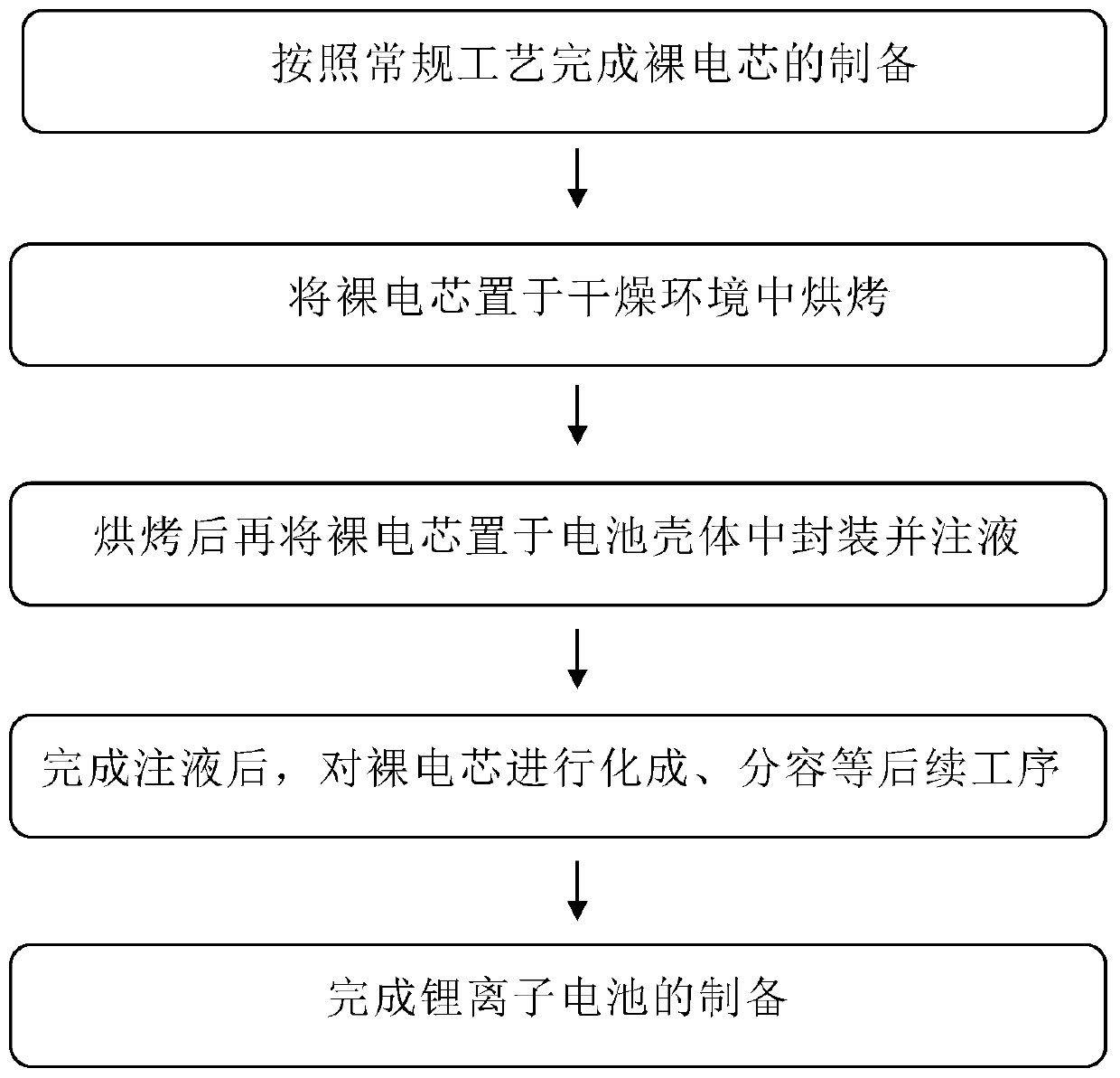

[0029] Such as Figure 1~2 Shown, a kind of manufacturing method of lithium-ion battery comprises the following steps:

[0030] S1, according to the conventional manufacturing process of lithium-ion batteries, a positive electrode sheet with lithium cobalt oxide as the positive electrode material and a negative electrode sheet with graphite as the negative electrode material are produced, and the positive electrode sheet, negative electrode sheet, and separator are laminated to form a bare cell.

[0031] S2. Baking the bare cell in a dry environment with a dew point temperature ≤ -35°C for 0.1 to 1.5 hours, preferably, 0.5 to 1 hour; The cells are packaged in the battery case for 10 minutes, and then injected in the same dry environment for about 20 minutes. Wherein, the bare cell is connected to the tab 1 having a channel 11 for the liquid injection process of the bare cell, and tab glue 2 is provided on the surface of the tab 1 . In addition, before the liquid injection, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com