Numerical control system online monitoring method

A numerical control system and function technology, applied in the field of numerical control, can solve the problems of unfavorable numerical control system online monitoring, difficult development, limited data collection, etc., and achieve the effect of real-time monitoring of processing trends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

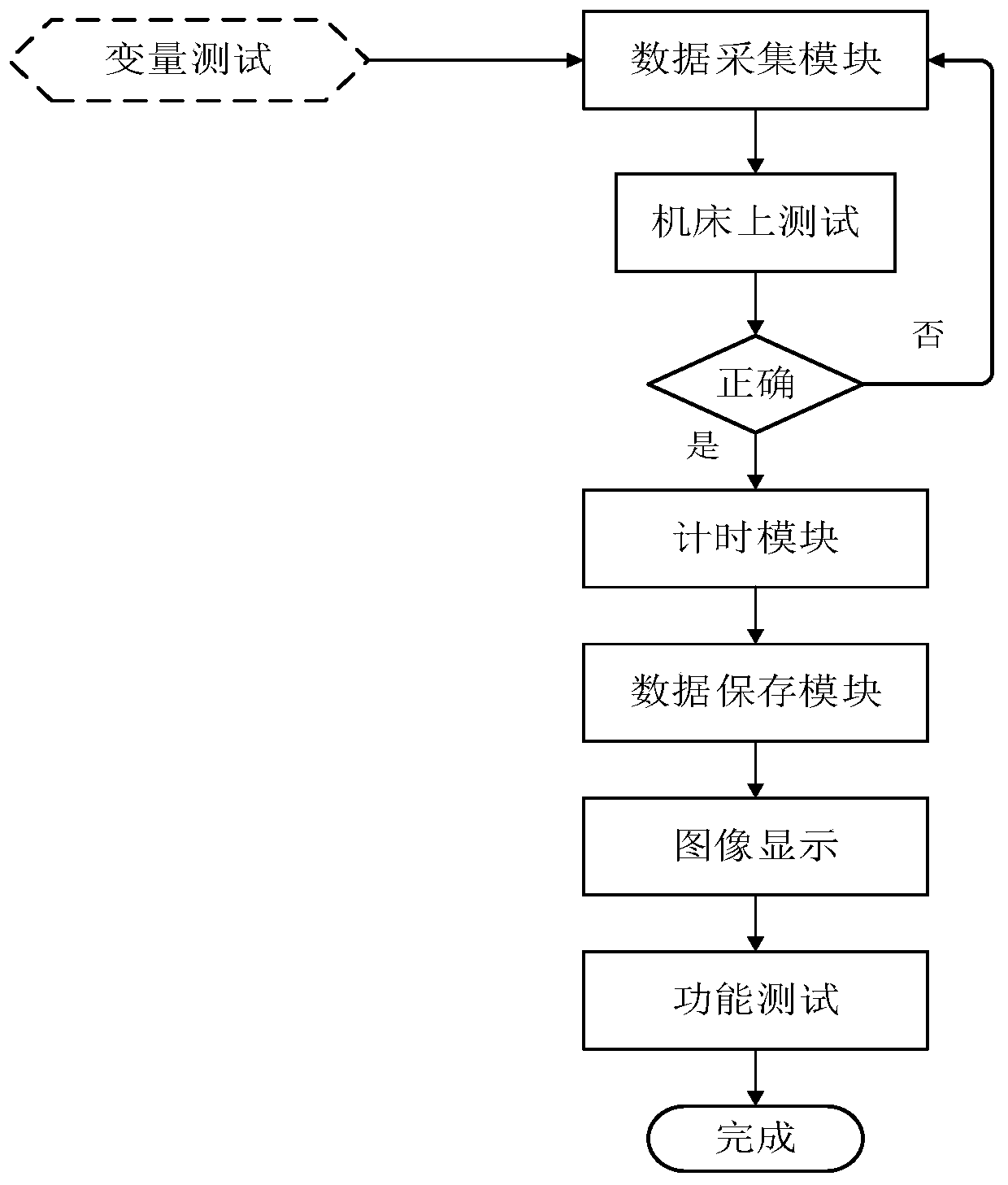

[0025] An online monitoring method of a numerical control system, comprising:

[0026] S1, search for variable data items, and verify whether the ID of the variable data item exists in the numerical control system, and if it exists, verify the correctness of its ID;

[0027] S2, obtaining variable data items with existing and correct IDs from the numerical control system;

[0028] S3, calculating the precise time for obtaining variable data items each time;

[0029] S4, drawing a curve diagram of the obtained variable data item changing with time;

[0030] S5. Store the obtained variable data items in a table according to the sampling frequency.

[0031] Further, in S1, variable data items include: NC program name, part number, part processing start time, part processing end time, cutting time, spindle speed, feed rate, machine coordinates and tool number.

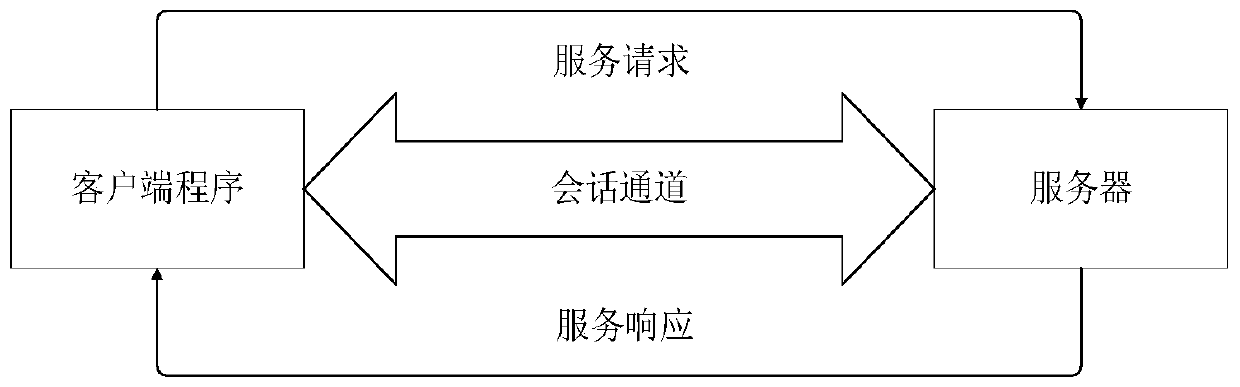

[0032] Further, in S2, variable data items in the numerical control system are acquired through dynamic data exchange...

specific Embodiment approach

[0037] Such as figure 1 , 2 As shown, the specific implementation of the online monitoring method of the numerical control system of the present invention is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com