Concrete spreading trolley, concrete spreader and trolley

A cloth trolley and car body technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of heavy workload and labor intensity, cumbersome operation, and long time consumption, so as to improve pouring efficiency, ensure pouring quality, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

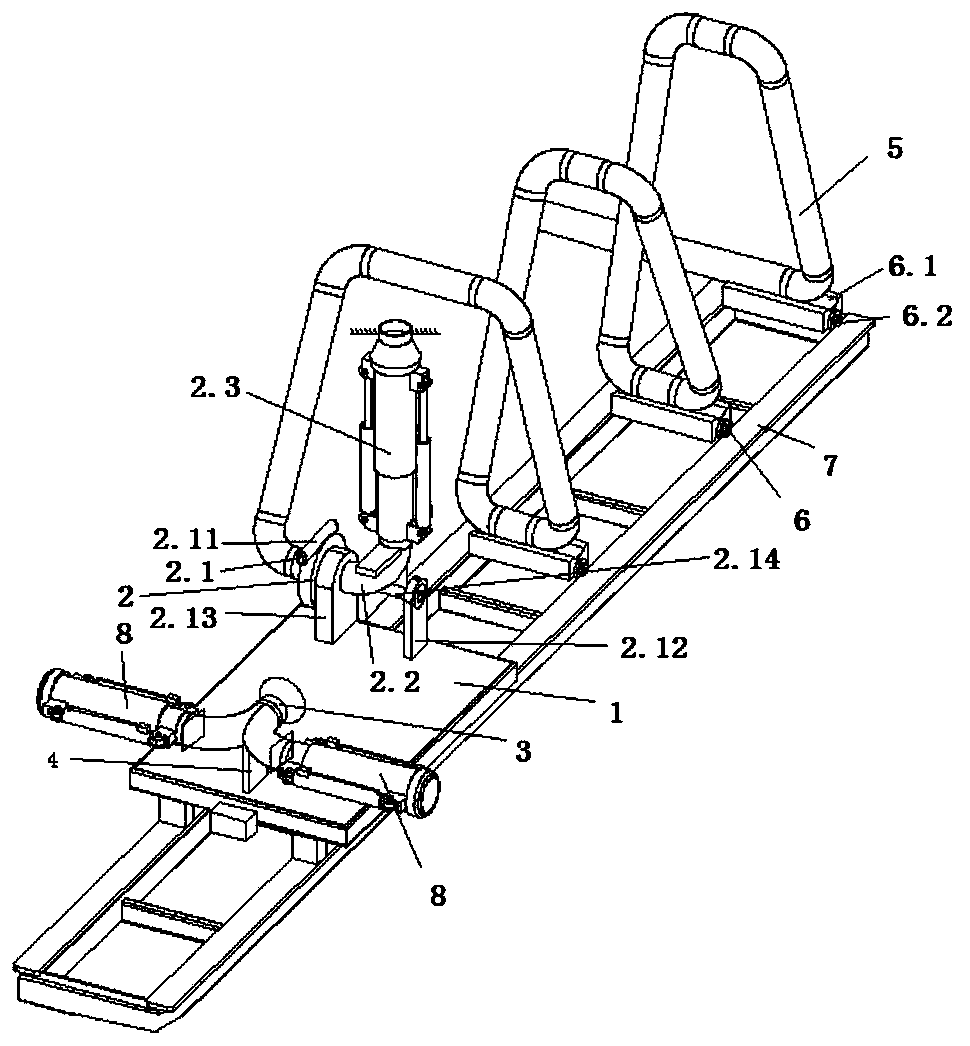

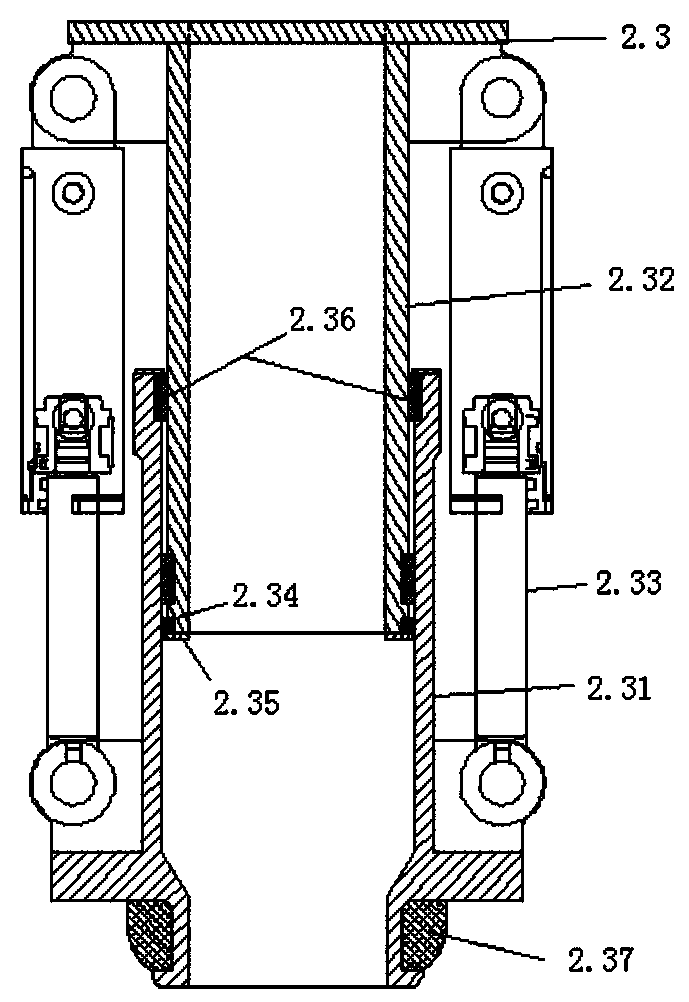

[0035] A concrete distributing machine, including a distributing trolley and a walking track 7 that facilitates the walking of the distributing trolley. The distributing trolley includes a car body 1, a rotating and telescopic connecting pipe 2, a discharge pipe 3 and a feeding pipe 5. For details, see figure 1 ,Details are as follows:

[0036] The car body 1 of the cloth trolley can walk back and forth along the walking track 7, and is used to drive the rotating telescopic connecting pipe 2, the discharge pipe 3 and the feeding pipe 5 to move, and the car body can be provided with a walking track that matches the walking track 7 Parts (such as roller sets), the cloth trolley can also include power components, and the power can be mechanical (oil cylinder, cylinder, fuel oil, gas, etc.), and the cloth trolley can also be manually driven to walk.

[0037] The feed pipe 5 includes at least two stretchable single pipes arranged in series, and the adjacent single pipes are movably...

Embodiment 2

[0048] A trolley, comprising the concrete placing machine as described in Embodiment 1, the placing trolley of the concrete placing machine is arranged on the walking track on the door frame of the trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com