Steel-reinforced beam load-bearing bar structure, construction method thereof and steel-reinforced concrete structure

A technology of a stressed steel bar and a construction method, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of preventing stirrups from binding vertical steel bars, uncontrollable installation accuracy, and low construction efficiency. , to achieve the effect of guaranteed construction quality, controllable thickness of protective layer and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

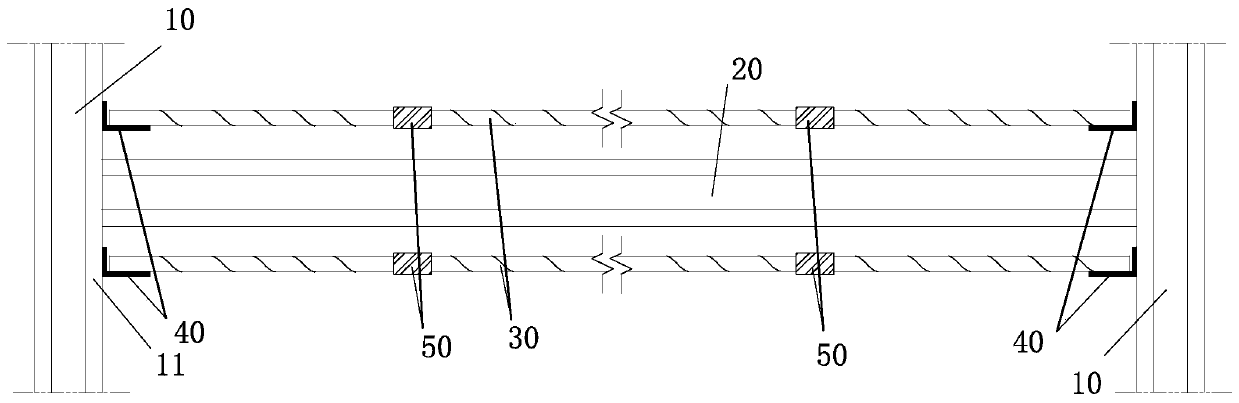

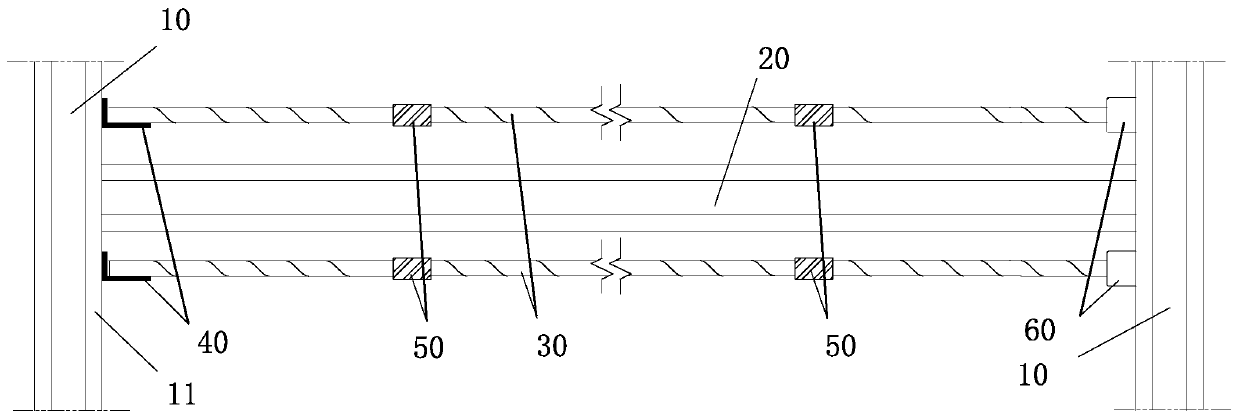

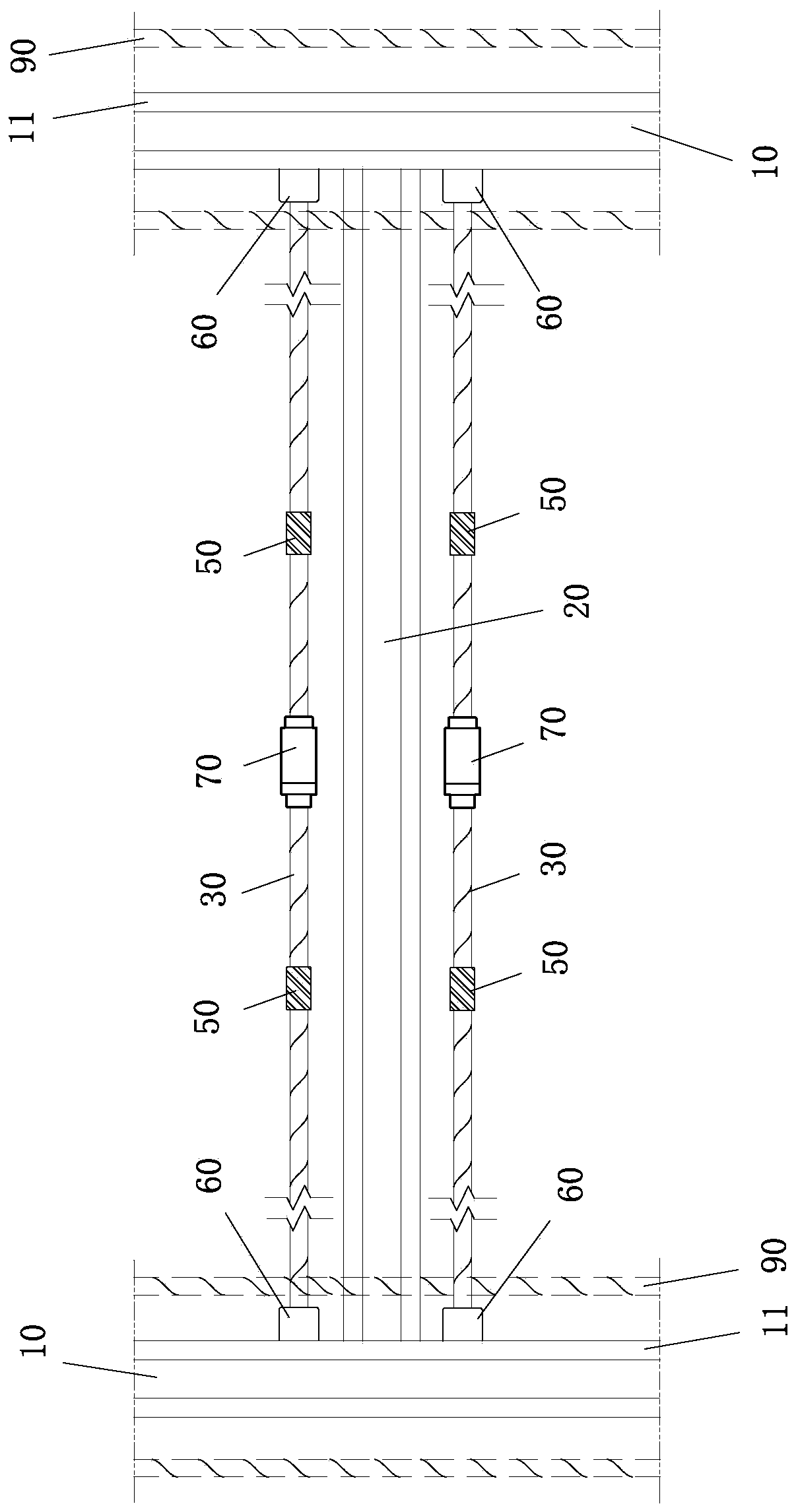

[0024] Such as Figure 3 to Figure 6 As shown, the reinforced steel bar structure of the steel frame beam of the present invention includes two steel bar sections installed between the flange plates 11 of the vertical steel bars 10 of the two steel bar columns, and one end of the two steel bar sections is connected to the corresponding vertical steel bar respectively. The connector 60 welded in advance on the flange plate 11 of 10 is screwed, and the other end of the two steel bar sections is connected to each other in the middle of the span by a double-screw sleeve 70, wherein: the steel bar section is a horizontal steel bar 30, Alternatively, when constructing a large-span steel-reinforced concrete structure with a span greater than 12 meters or when constructing a large-span steel-reinforced concrete structure that requires at least three transverse steel bars 30 to form a steel bar section, the steel bar section is passed through the straight threaded sleeve 50 A plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com