Construction method of stiffening core curtain pile and wall protection pile anchor combined supporting structure

A technology of combined support and construction methods, applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problem that its own strength is not fully utilized, and achieve the effects of avoiding underground space pollution, saving materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

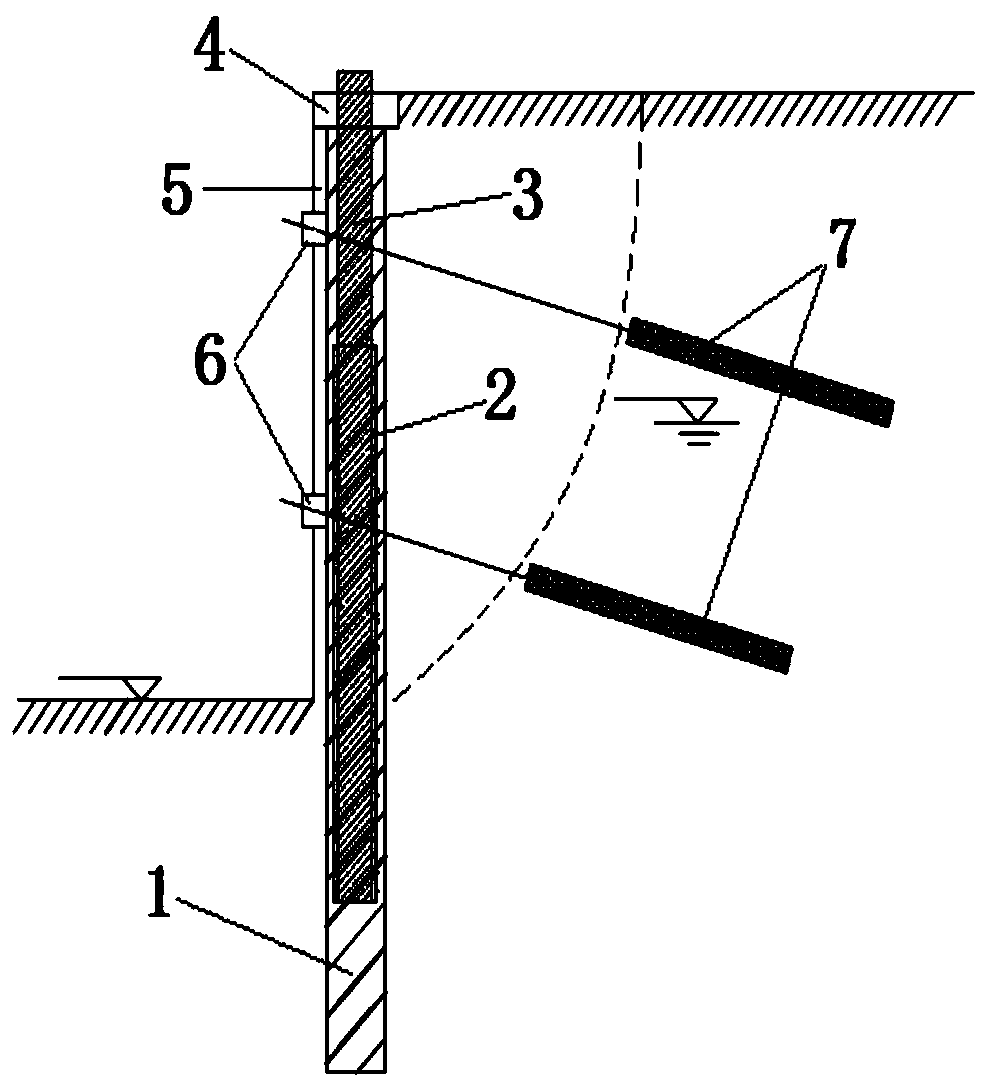

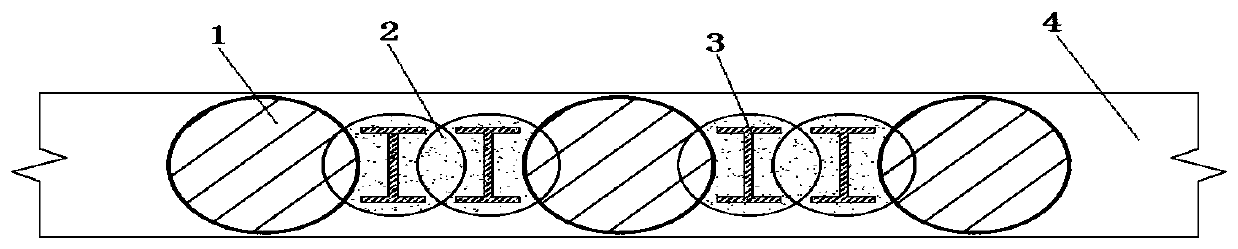

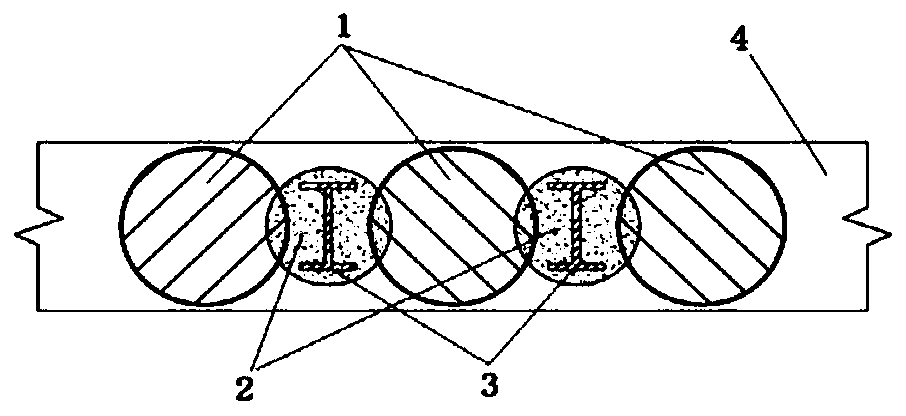

[0030] Such as Figure 1-4 As shown, a joint support structure of core curtain pile and retaining pile anchor includes concrete pouring pile 1, water-stop curtain 2, section steel core 3 and crown beam 4, and the water-stop curtain 2 is a high-pressure jet grouting pile water-stop Curtain, the steel core 3 is driven into the water-stop curtain 2 along the axis to form a core water-stop curtain, the core water-stop curtain is arranged at intervals with the concrete cast-in-place piles and arranged in a straight line interlocking with each other, and the adjacent concrete cast-in-place piles 1 to 2 high-pressure jet grouting piles are arranged according to the pile spacing, the crown beam 4 connects the concrete pouring pile 1 and the core water-stop curtain as a whole, and the waist of the concrete pouring pile 1 is connected with a waist beam 6, The prestressed anchor rod 7 is installed on the waist beam 6 between two adjacent concrete pouring piles 1, and the outer end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com