Water level brake with function of precisely controlling lifting height for river engineering model

A river engineering model and controllable technology, which is applied to hydraulic models and other directions, can solve the problems of low control accuracy of lifting height, and achieve the effects of saving energy, reducing power, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

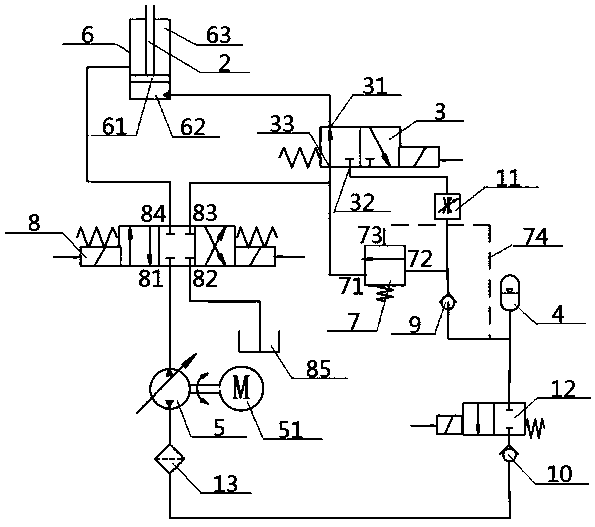

[0038] see figure 1 — figure 2 , the present invention includes two processes of descending and rising of the water level gate 1 during application.

[0039] During the descent: at the beginning of the descent, there is no pressure oil in the accumulator 4, and the electromagnet on the two-position three-way electromagnetic reversing valve 3 is energized to conduct the oil circuit between the upper oil inlet 31 and the outlet oil port 33 , and then the hydraulic oil in the cylinder oil chamber 62 flows into the accumulator 4 for storage through the speed regulating valve 11 and the No. 1 check valve 9 successively under the action of gravity, and at the same time, with the outflow of the hydraulic oil, The piston 61 falls naturally under the action of gravity, and drives the water level gate 1 to descend through the push rod 2 .

[0040] During the ascent process: at the beginning of the ascent, the accumulator 4 has already stored the hydraulic oil input during the previou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com