Device for early warning of structure damage according to stress monitoring

A stress monitoring and structure technology, applied in textiles, papermaking, textile cables, etc., can solve the problems of slow update rate, poor robustness, and complicated operation, and achieve the effect of ensuring reliability, reasonable design and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

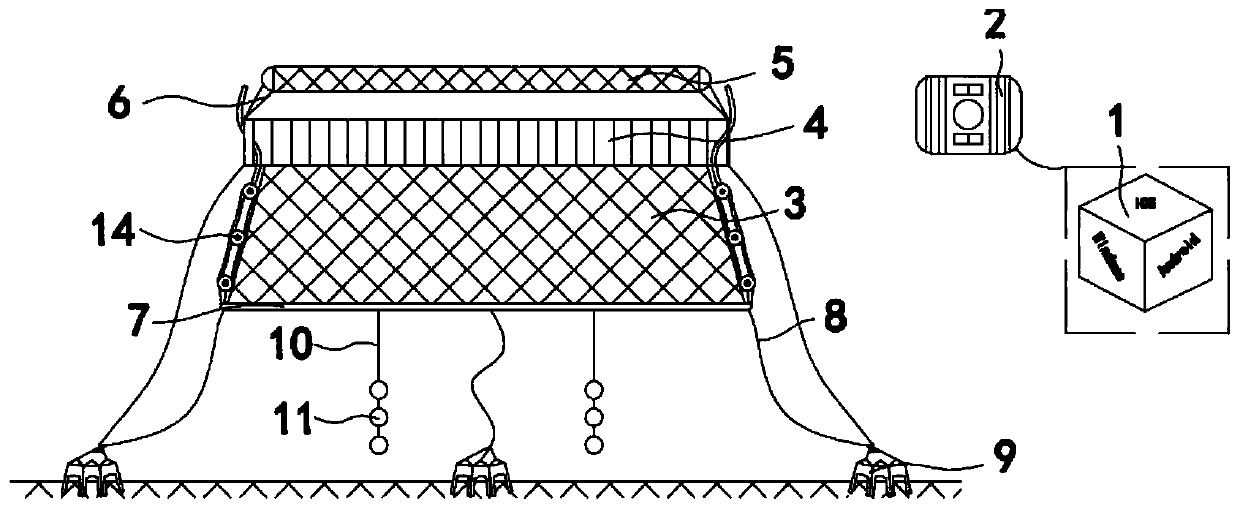

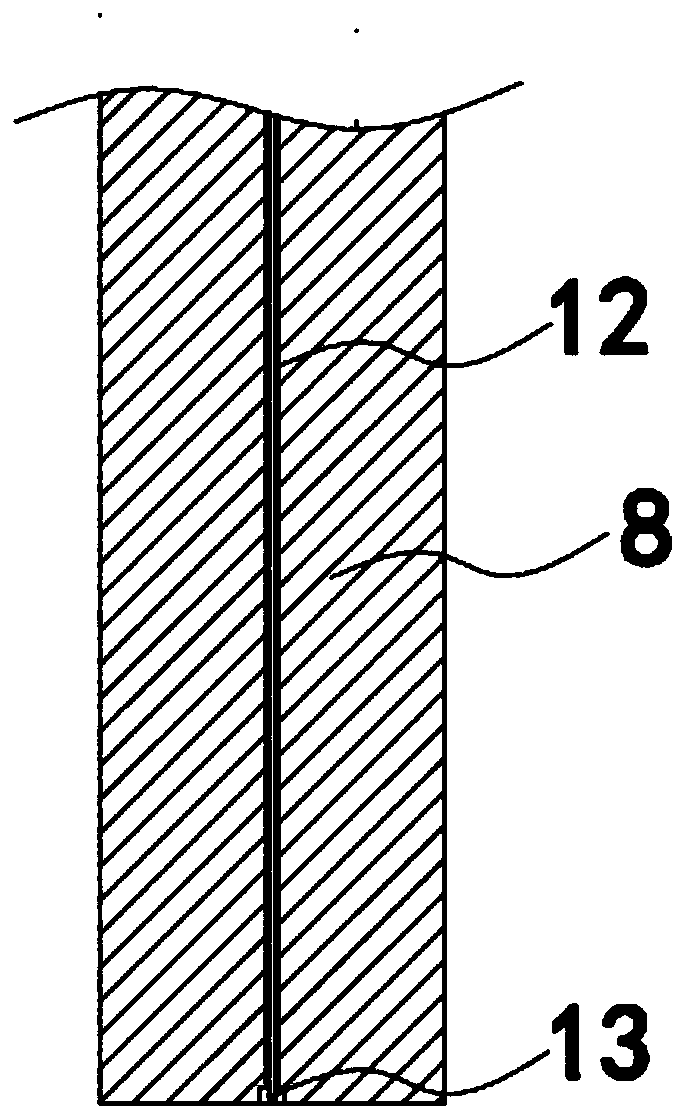

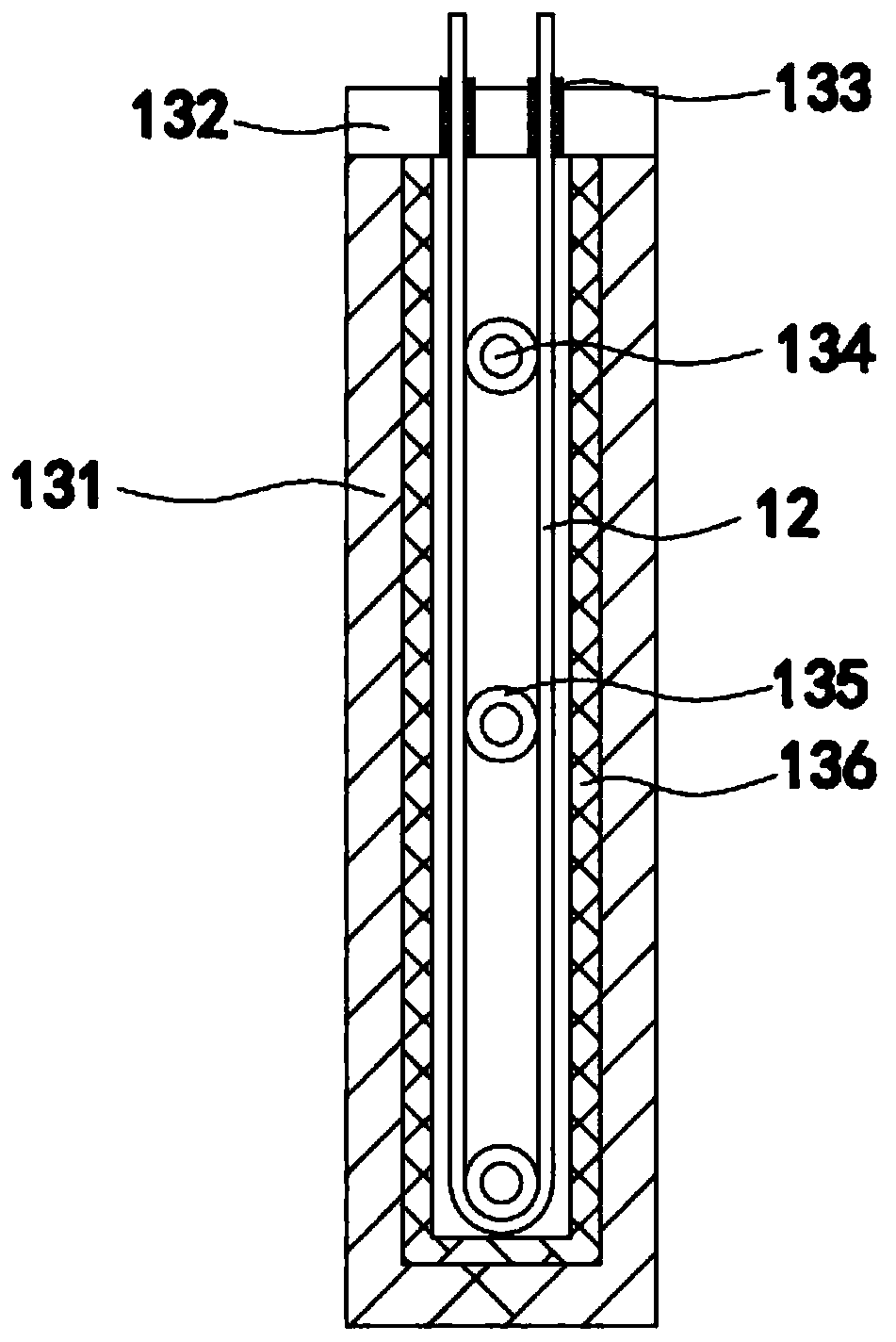

[0027] like Figure 1-6 As shown, a device for early warning of structural damage based on stress monitoring includes a mobile terminal 1, a data processor 2, and a netting 3. The top of the netting 1 is connected to a top frame 4, and the bottom of the netting 1 is provided with a bottom frame 7. The bottom surface of the frame 7 is connected with the peripheral lower edge of the top frame 4 with a cable 8. The cable 8 is braided by multiple strands, and the inside of the cable 8 is woven with an optical fiber 12. 13 includes a top cover 132, the top cover 132 is connected to the housing 131 through threads, the top of the top cover 132 is symmetrically provided with an anti-wear sealing ring 133, and the inside of the housing 131 is provided with at least three fixed shafts 134 longitudinally, and each fixed shaft 134 is A rotating shaft 135 is sheathed, and a rubber layer 136 is adhered to the inner wall of the casing 131 . The cable of the present invention is internally ...

Embodiment 2

[0039] like Figure 1-6 As shown, the workflow of the device is as follows Figure 5 As shown: the cable 8 is connected at the edge of the lower end of the net 1 and the edge of the top frame 4, and then the cable 8 is tied to the anchor body 9, and the cable 8 at the bottom of the net 1 is impacted by waves and waves. The optical fiber 12 inside the cable 8 will check the tension of the cable 8 every time, and send the monitored raw data to the data processor 2 through wireless signal transmission, and the data processor 2 analyzes the raw data, technology, and then transmit the processed data to the mobile terminal 1 for display, and the operator analyzes and judges the output tension value, whether it exceeds the bearing capacity of the cable 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com