Trolley absolute value encoder transmission fixing device with protective cover for automatic rubber tired container gantry crane

An absolute encoder and fixing device technology, applied in safety devices, trolley cranes, transportation and packaging, etc., can solve problems such as monitoring real-time position accuracy deviation, and achieve the effect of optimizing positioning accuracy and achieving precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

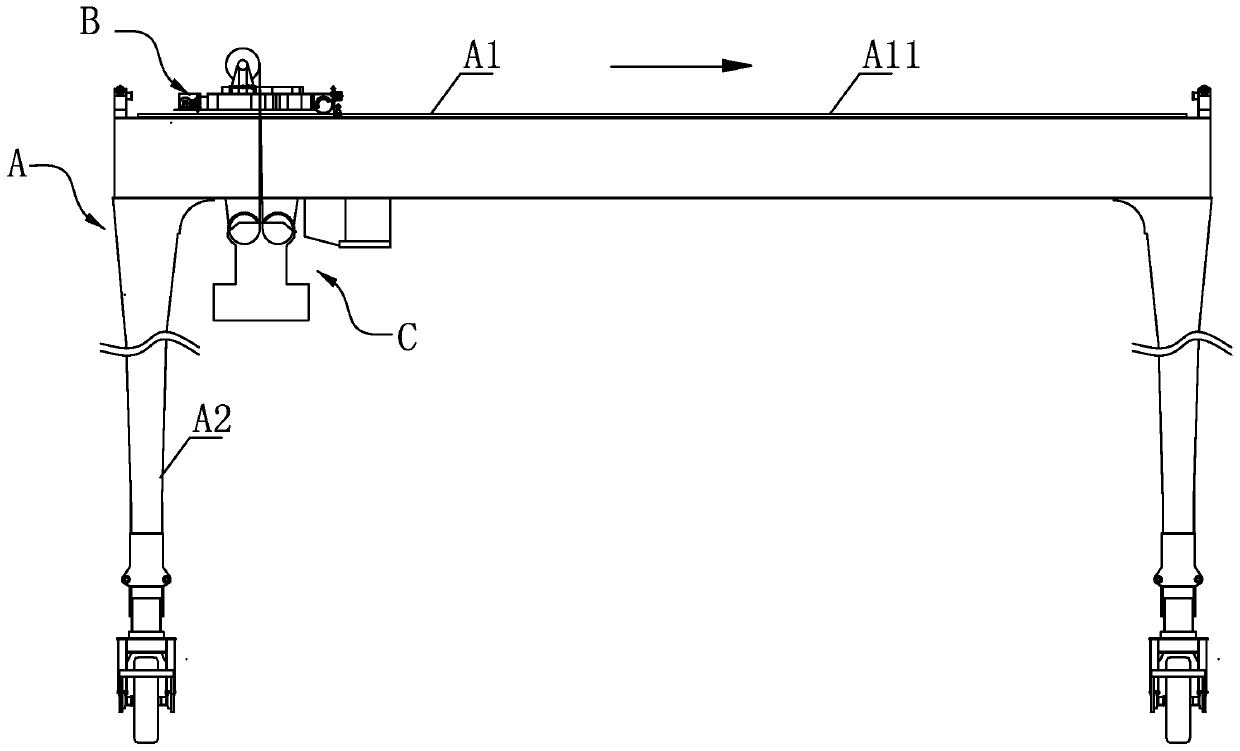

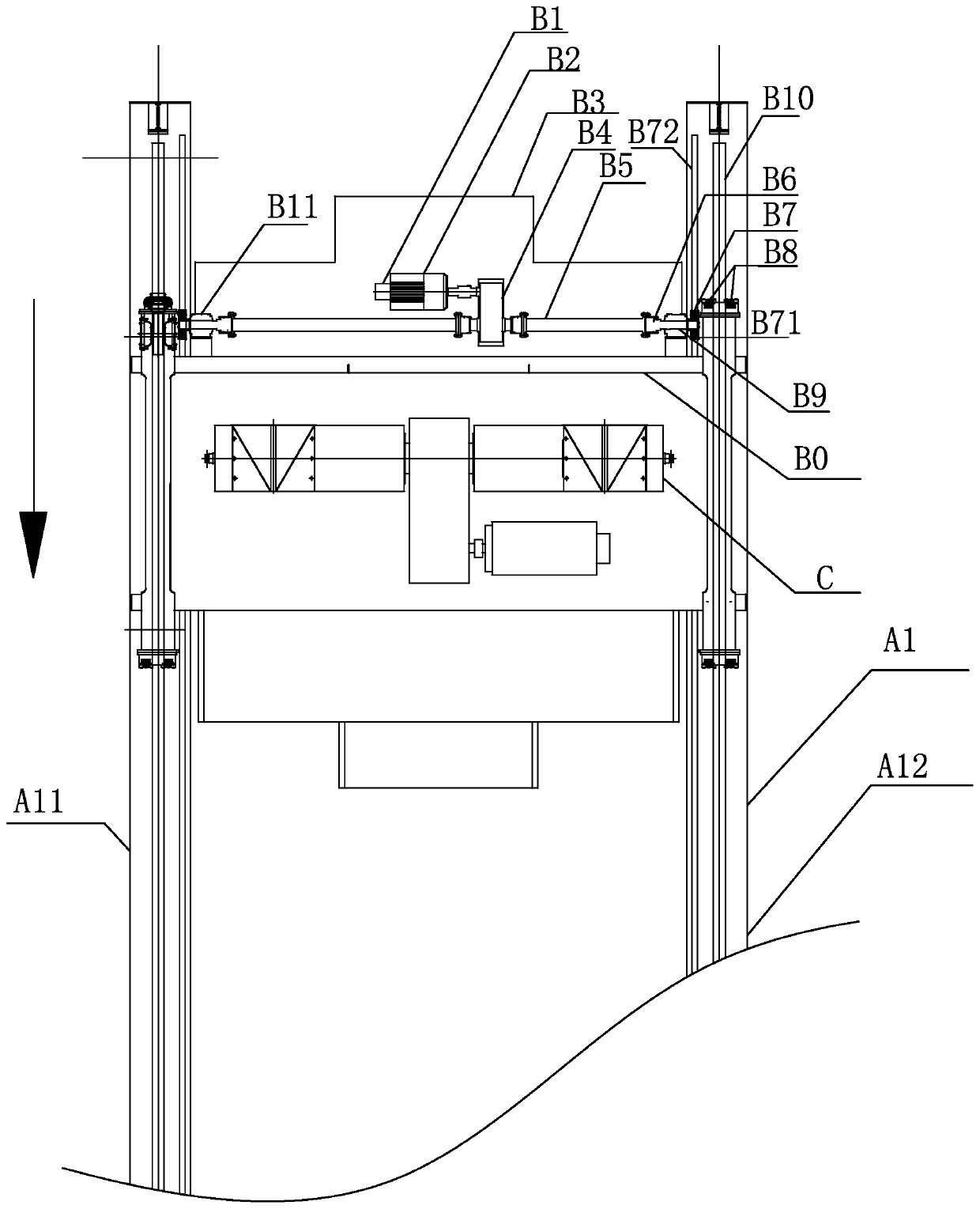

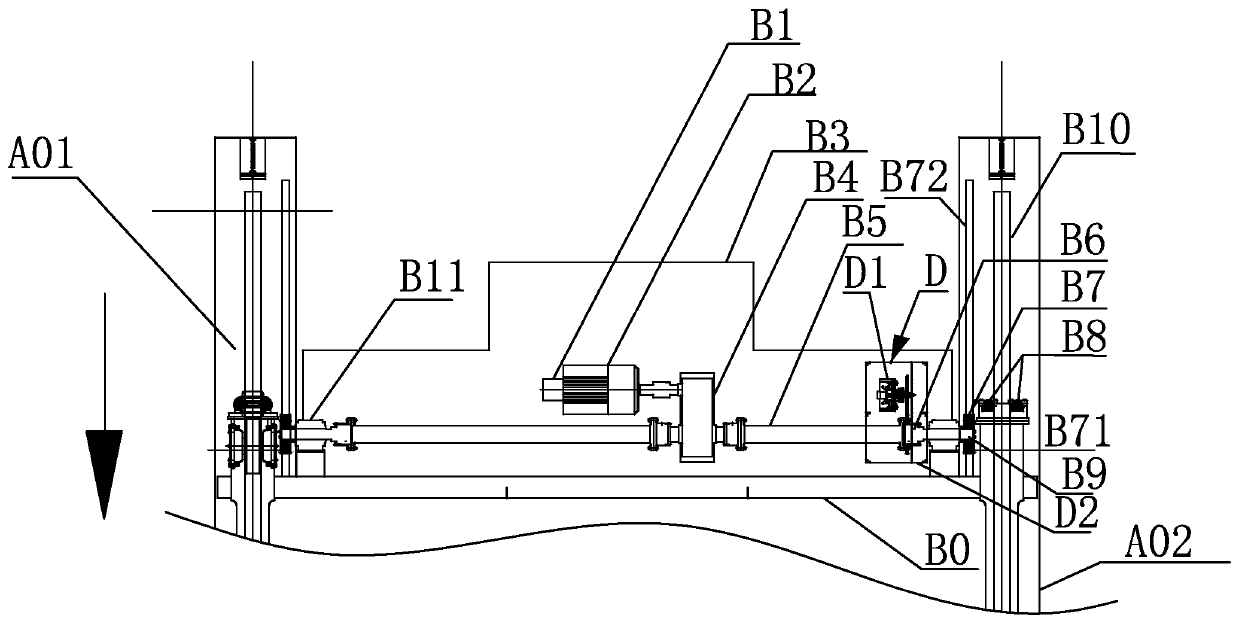

[0025] Figure 3-Figure 7 It shows an absolute value encoder transmission and fixing device D for a trolley with a protective cover for an automated field bridge and its application in the trolley B of an existing field bridge. As mentioned above, in the existing field bridge, the trolley B reciprocates along the top beam A1 through the trolley driving mechanism arranged between the front and rear walls A11 and A12 of the field bridge gantry type cart A top beam A1. The driving mechanism of the trolley includes a motor B2 integrally equipped with an incremental encoder B1, a reducer B4 connected to the motor, a low-speed output shaft B5 of the reducer, a coupling B6, and a drive shaft B9 of the trolley. The trolley gear B71 and the rack and pinion meshing mechanism B7 formed by the rack B72 laid on the top edge of the front and rear walls A11 and A12 of the large roof beam, the slide rail B10 laid on the top edge of the front and rear walls of the large roof beam and the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com