Flexible rack for material conveyor and belt conveyor

A conveyor and rack technology, applied in the field of flexible racks and belt conveyors for material conveyors, can solve the problems of lack of displacement compensation function and inability to meet the needs of complex use environments, so as to avoid insufficient connection strength and avoid The effect of deformation and large displacement compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

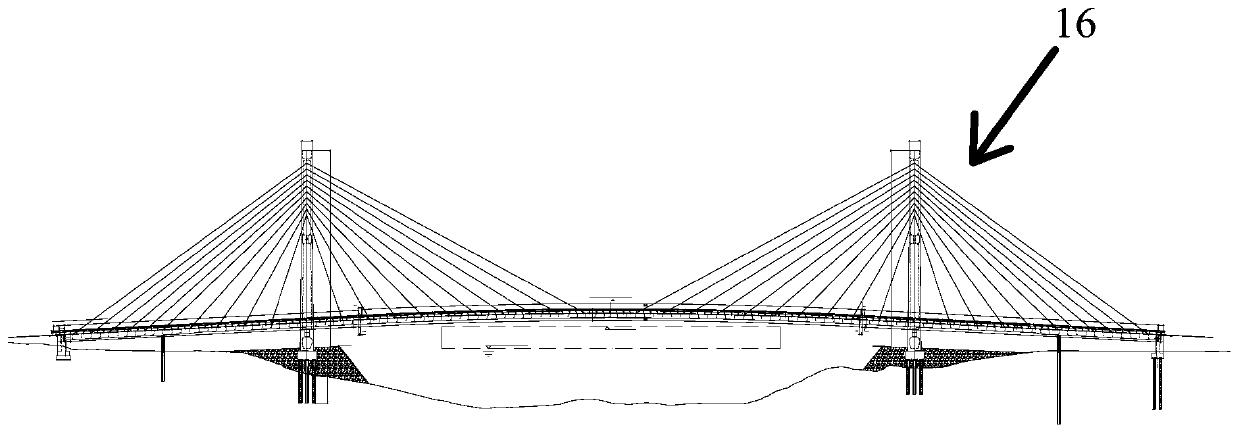

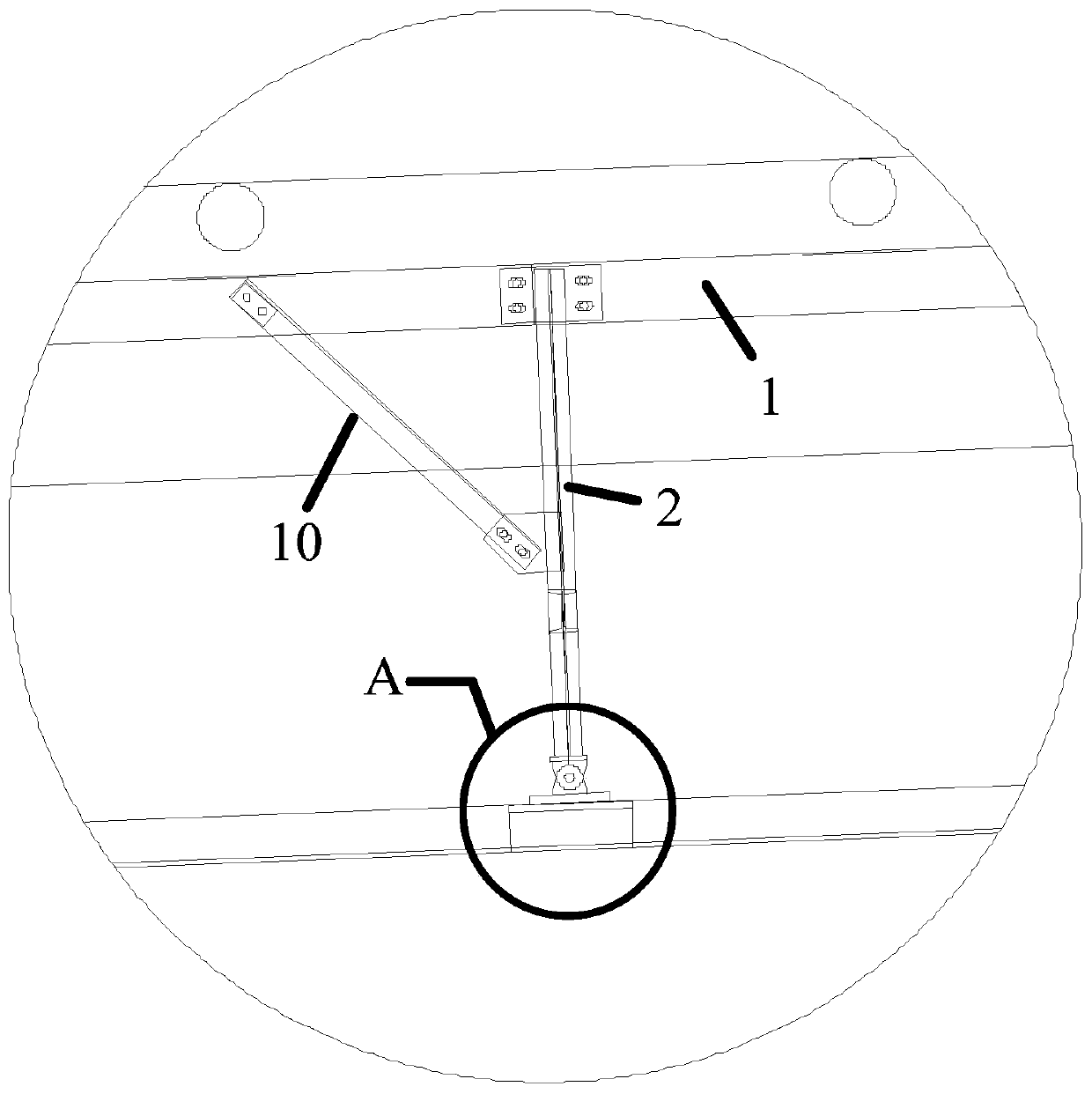

[0041] A belt conveyor with a flexible frame is described as figure 2 As shown, the belt conveyor is set on a longer river-crossing or sea-crossing cable-stayed bridge. The two ends of the above-mentioned bridge 16 are movable, and due to wind load, thermal expansion and contraction, etc. A linear displacement is produced, and a bending perpendicular to the axial direction of the bridge 16 is produced. The belt conveyor located on the above-mentioned bridge 16 has a flexible frame. flexible racks, such as figure 1 shown, which includes:

[0042] Rack body 1, such as Figure 7 As shown, the material is arranged on the frame body 1, and is driven to move to a designated position; the frame body 1 is a segmented structure, and the frame body 1 includes a middle frame 14, and the The end frame 15 at both ends of the middle frame 14; a telescopic gap is arranged between the middle frame 14 and the end frame 15, and the frame body 1 of the above-mentioned segmented structure ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com