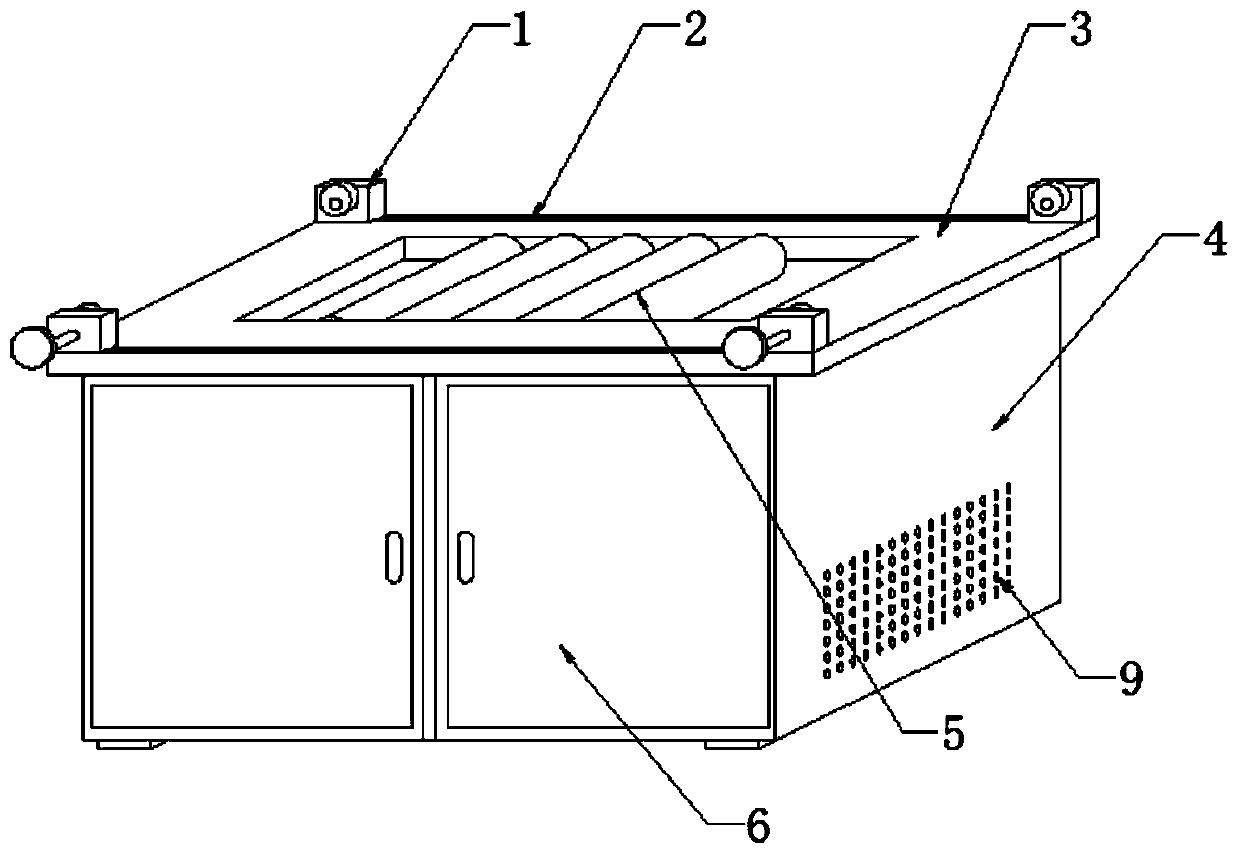

Fiberboard surface shaping processing device

A processing device, fiberboard technology, used in grinding drives, metal processing equipment, grinding/polishing safety devices, etc., can solve a large number of debris, no debris collection equipment, fiberboard processing equipment can not meet the surface of different thickness plates Deal with needs and other issues to achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

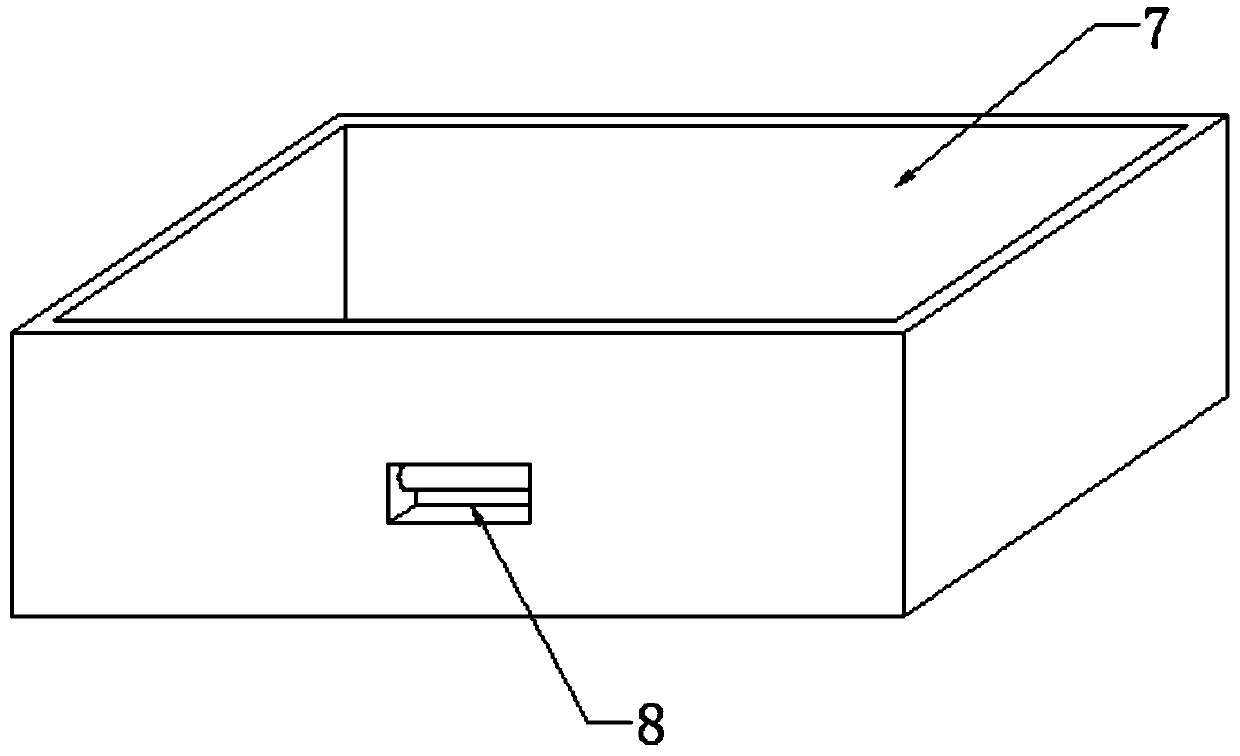

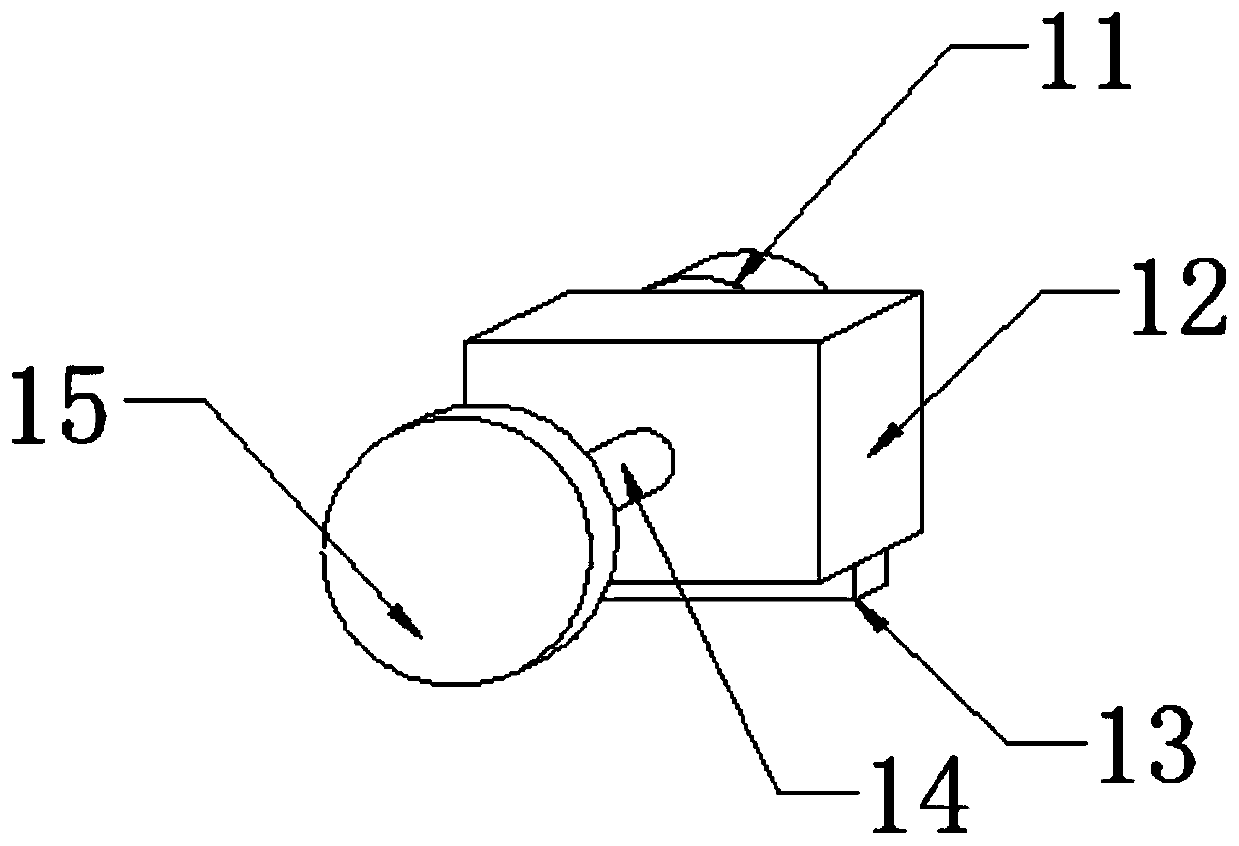

[0025] Specific implementation method: first, the rotation of the turntable 15 drives the rotating rod to rotate, and the rotation of the rotating disk 15 drives the rotating rod to pass through the rotation damper 12 and fix it with the eccentric roller 11. frictional force, and then it is convenient to rotate the eccentric roller 11 through the turntable 15, and the distance between the lowest end of the eccentric roller 11 and the upper end surface of the processing table 3 changes during the rotation of the eccentric roller 11. This design is convenient for different thicknesses. The rotation of the eccentric roller 11, this design limits the amplitude of the upward movement of the plate, and then drives the grinding roller 5 to rotate through the drive motor, and then the rubber roller sleeve 16 set on the eccentric roller 11 contacts with the upper end surface of the plate. The magnitude of the upward movement is convenient for the grinding roller 5 to process the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com