Double-mode control gas stove

A dual-mode control, gas stove technology, applied in the field of gas stoves, can solve the problems of inability to realize automatic control, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

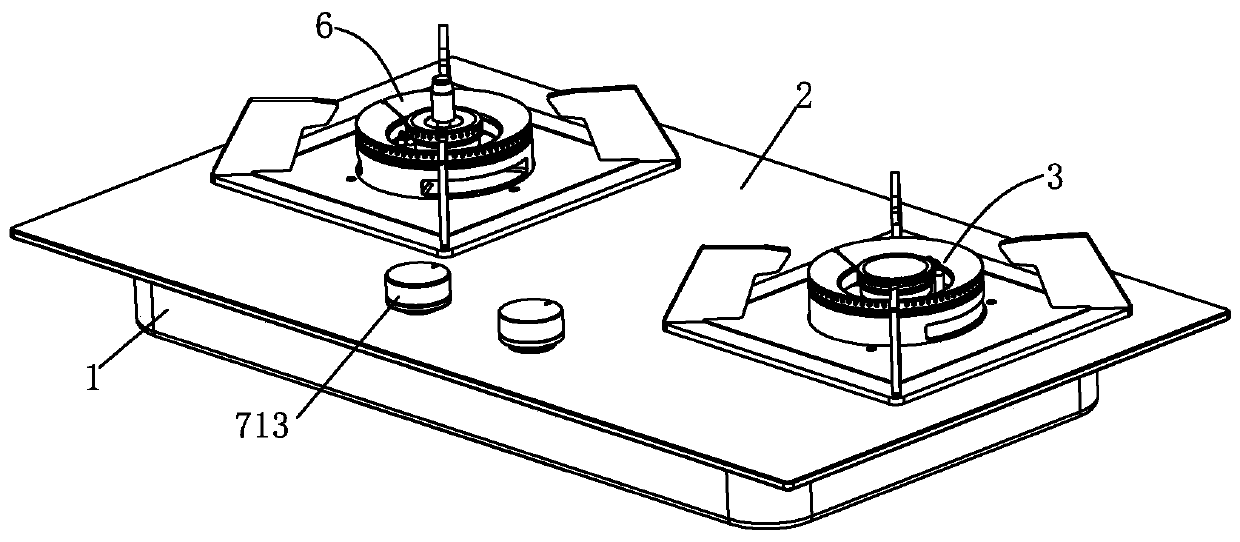

[0024] like figure 1 , figure 2 As shown, a dual-mode control gas stove includes a bottom shell 1 with an upper opening, a panel 2, a burner 3, a gas regulating valve 4 and a gas distribution rod 5, and the panel 2 is provided with a burner through hole and a valve stem. The upper part of the burner 3 protrudes through the hole through the burner; the gas regulating valve 4 communicates with the distributing rod 5, and the gas regulating valve 4 cooperates with the burner.

[0025] It also includes an anti-dry burner 6, a band switch assembly 7, a main control board (not shown in the figure), a control box 9 and an electric control valve 10,

[0026] like Figure 10 As shown, the anti-dry burner 6 includes an inner injection pipe 61, an outer injection pipe 62 and a telescopic temperature sensor 63; the telescopic temperature sensor 63 detects the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com