Stacking automatic thatch machine retractable girder

A telescopic beam and automatic technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of low operating efficiency, high labor intensity of workers, and harsh working environment, so as to improve work efficiency, increase stability and The effect of using intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

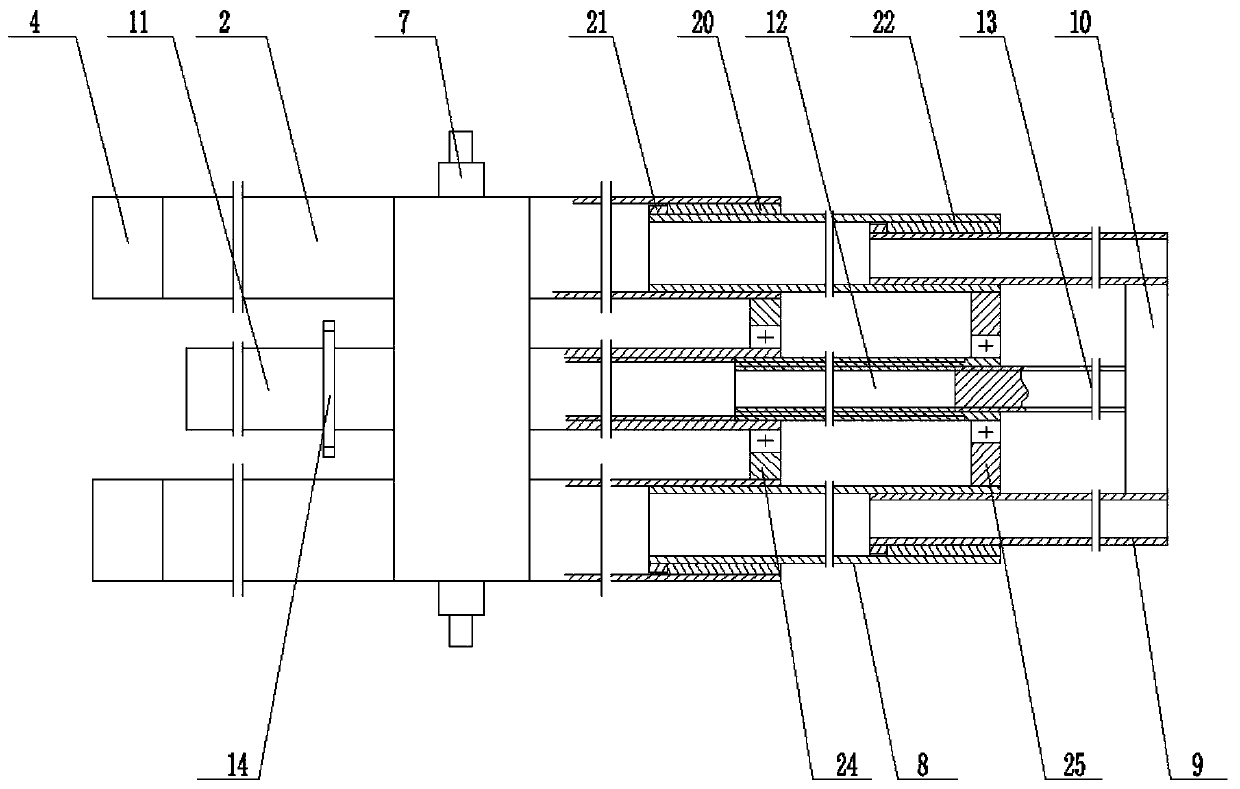

[0029] See attached Figure 1-3 As shown: the present invention provides a retractable beam of a stacking automatic thatch machine, which consists of a column 1, a fixed beam 2, a walking vehicle, a counterweight iron 4, a U-shaped beam 5, a reel 6, and a servo motor directly connected to a reducer 7 , primary telescopic beam 8, secondary telescopic beam 9, connecting arm 10, nut sleeve 11, nut screw 12, screw 13, large drive gear 14, small drive gear 15, bearing seat 16, counterweight wire rope 17, Fixed steel wire rope 18, rolling bearing 19, primary guide plate 20, limit block 21, secondary guide plate 22, telescopic steel wire rope 23, fixed beam connecting arm 24, telescopic beam connecting arm 25 and other components, mainly including The column 1, the fixed beam 2 for installing the telescopic beam, the telescopic beam and the trolley for realizing the girder, the column 1 is sequentially equipped with traction devices and the fixed beam 2 from top to bottom, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com