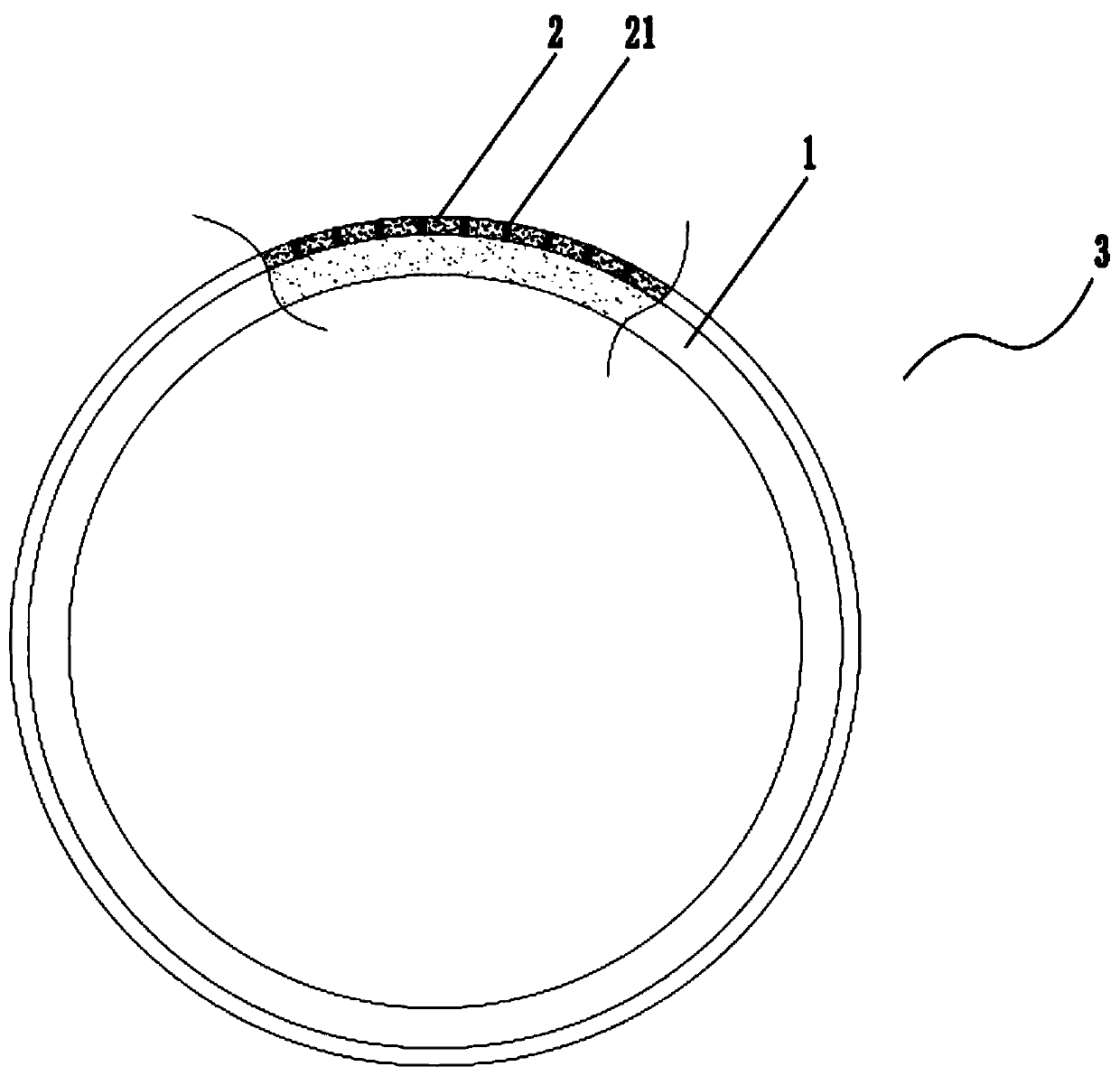

Rubber piece and application thereof in connecting pieces and protective pieces

A technology of rubber parts and protective parts, applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve the problems of lack of research on rubber regulation and control, difficulty in obtaining technical personnel, mutual reference and inspiration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

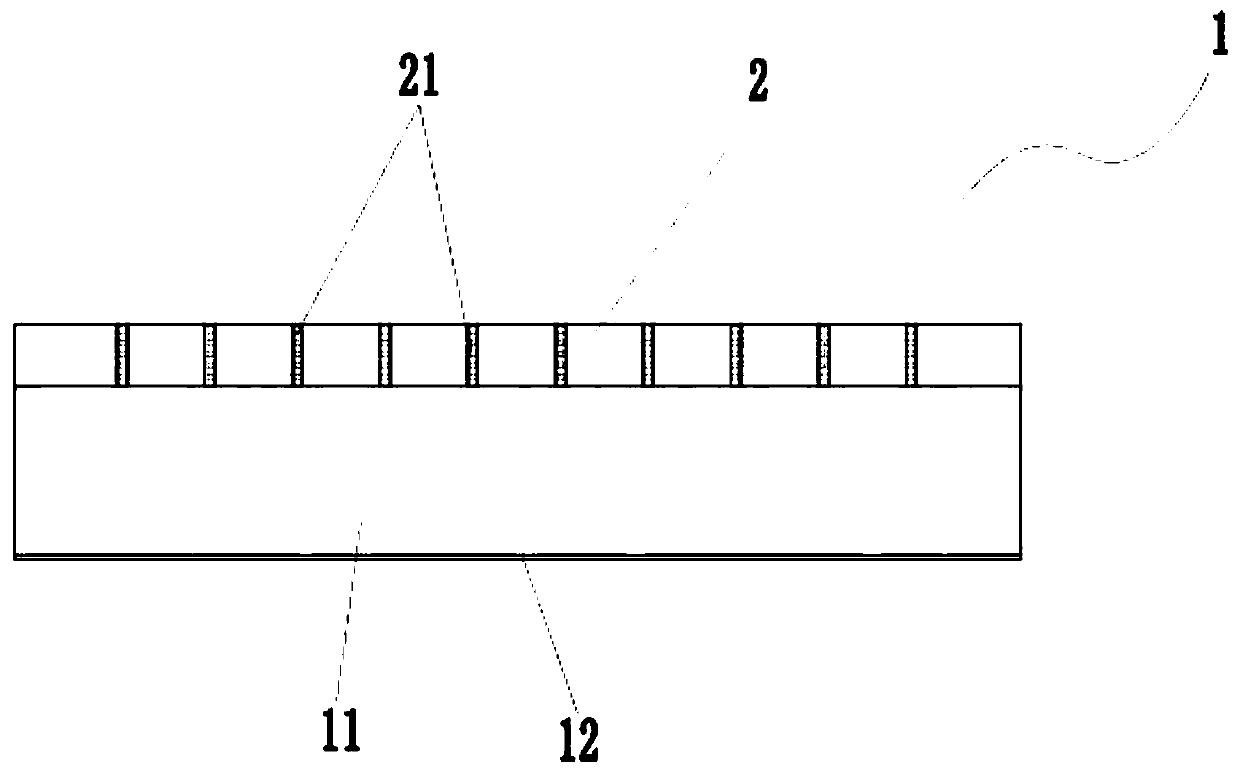

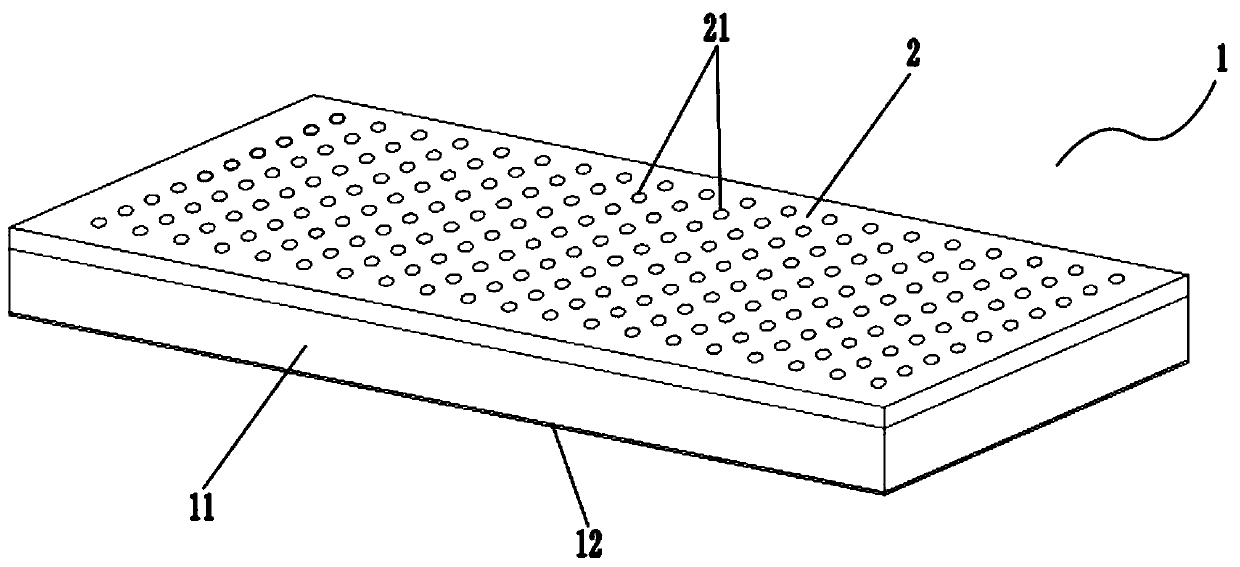

[0079] Based on the above, the program also provides a method for preparing a rubber part, which includes the following steps:

[0080] (1) Prepare the rubber strip body, which specifically includes at least mixing styrene-butadiene rubber, zinc oxide, stearic acid, paraffin oil and carbon black in an environment of 40-50°C, and then controlling the humidity of the mixing container to be lower than 50%. Add nano-bentonite for further mixing; then add ethylene thiourea as a vulcanizing agent and carry out mixing treatment at 80-100 ℃ for 20-25 minutes, and then shape it into a strip body blank and keep it at a constant temperature;

[0081] (2) Prepare a reinforcement layer, and then form several through holes on the surface of the reinforcement layer, which specifically include at least neoprene rubber, fatty acid, isopropanol, N-(1,3-dimethyl)butyl-N' -Phenyl-p-phenylenediamine was mixed uniformly at 45-55 °C, then tetramethylthiuram monosulfide was added as a vulcanizing age...

Embodiment 1

[0086] A kind of preparation method of rubber part, it comprises the steps:

[0087] (1) Prepare the rubber strip body, which specifically includes at least mixing 40 parts of styrene-butadiene rubber, 1.0 parts of zinc oxide, 0.4 parts of stearic acid, 3 parts of paraffin oil and 3 parts of carbon black in an environment of 40-50 °C, Then control the humidity of the mixing container to be lower than 50%, add 0.1 part of nano-bentonite for further mixing; then add 0.2 part of ethylene thiourea as a vulcanizing agent and carry out mixing treatment at 90 ℃ for 20-25 minutes, and then shape it into a rubber strip The body blank is kept at a constant temperature;

[0088] (2) Prepare the reinforcement layer, and then form several through holes on the surface of the reinforcement layer, which specifically include at least 30 parts of neoprene rubber, 0.2 parts of fatty acid, 1 part of isopropanol, 0.5 parts of N-(1,3-di Methyl)butyl-N'-phenyl-p-phenylenediamine was mixed uniformly...

Embodiment 2

[0092] A kind of preparation method of rubber part, it comprises the steps:

[0093] (1) Prepare the rubber strip body, which specifically includes at least mixing 50 parts of styrene-butadiene rubber, 1.1 parts of zinc oxide, 0.5 parts of stearic acid, 4 parts of paraffin oil and 4 parts of carbon black in an environment of 40-50 °C, Then control the humidity of the mixing container below 50%, add 0.2 parts of nano-bentonite for further mixing; then add 0.2 parts of ethylene thiourea as a vulcanizing agent and carry out mixing treatment at 90 ℃ for 20-25 minutes, and then shape it into a rubber strip The body blank is kept at a constant temperature;

[0094] (2) Prepare the reinforcement layer, and then form several through holes on the surface of the reinforcement layer, which specifically include at least 50 parts of neoprene rubber, 0.4 parts of fatty acid, 2 parts of isopropanol, 1 part of N-(1,3-di Methyl)butyl-N'-phenyl-p-phenylenediamine was mixed uniformly at 45-55 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com