Intelligent logistics robot for a factory

A technology of intelligent logistics and robots, applied in the direction of hoisting devices, etc., can solve the problems of untimely steering, hysteresis of steering steering, hidden safety hazards, etc., and achieve the effects of timely steering, sensitive steering, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

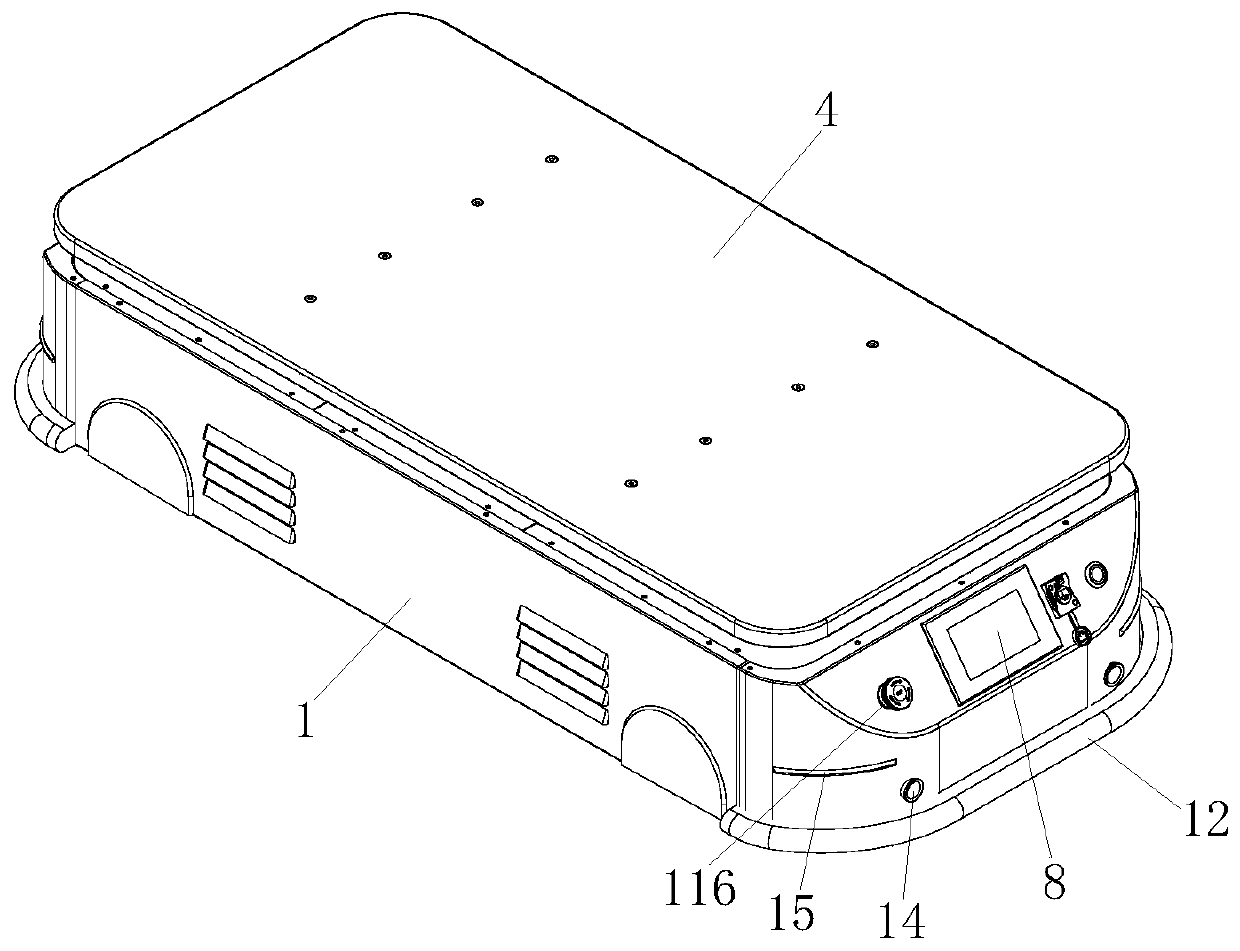

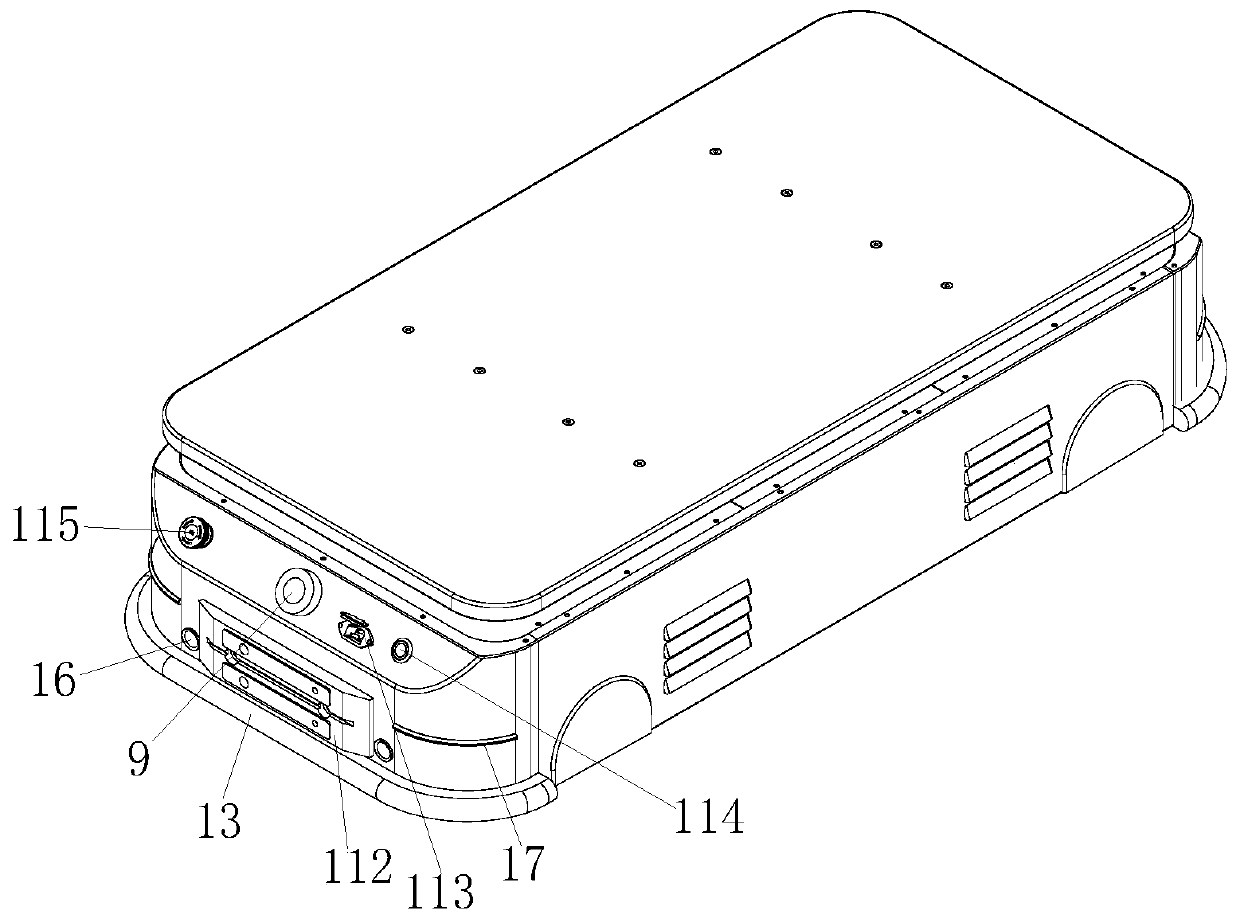

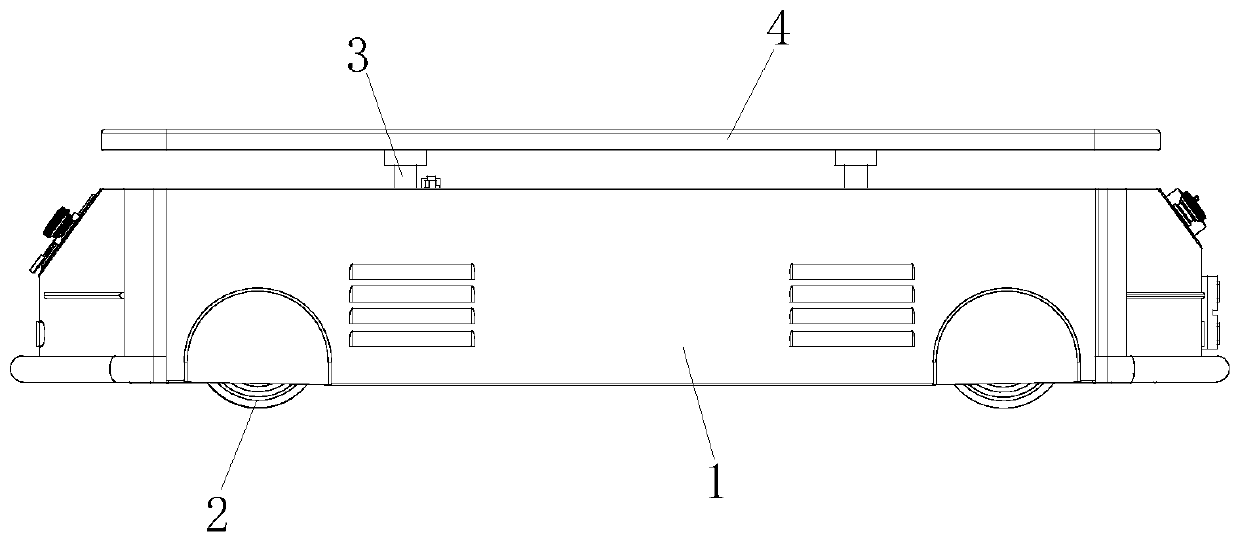

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0030] As shown in the figure, an intelligent logistics robot in the factory area of the present invention is provided, including a body 1, a wheel device is provided at the bottom of the body 1, at least one of the wheel devices is an automatic steering wheel device 2, and the body 1 is equipped with There is a lifting device 3, the top of the jacking device 3 is connected to the lifting plate 4, the bottom of the body 1 is also provided with a guide signal collector, and the body 1 is provided with a central controller 5, the guide signal collector and the central controller 5 Communication connection, the central controller 5 is in communication connection with the automatic steering wheel device 2 and the lifting device 3 .

[0031] Described automatic steering wheel device 2 comprises wheel frame 21, steering motor 23, and described wheel frame 21 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com