Rolling mechanism for enzyme deactivation of tea leaves

A technology for killing green leaves and tea leaves, which is applied in the direction of tea processing before extraction, can solve the problems of energy consumption, laborious rotation of the rolling barrel, and high cost of the rolling machine, and achieve the effect of improving the rolling effect, full rolling, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

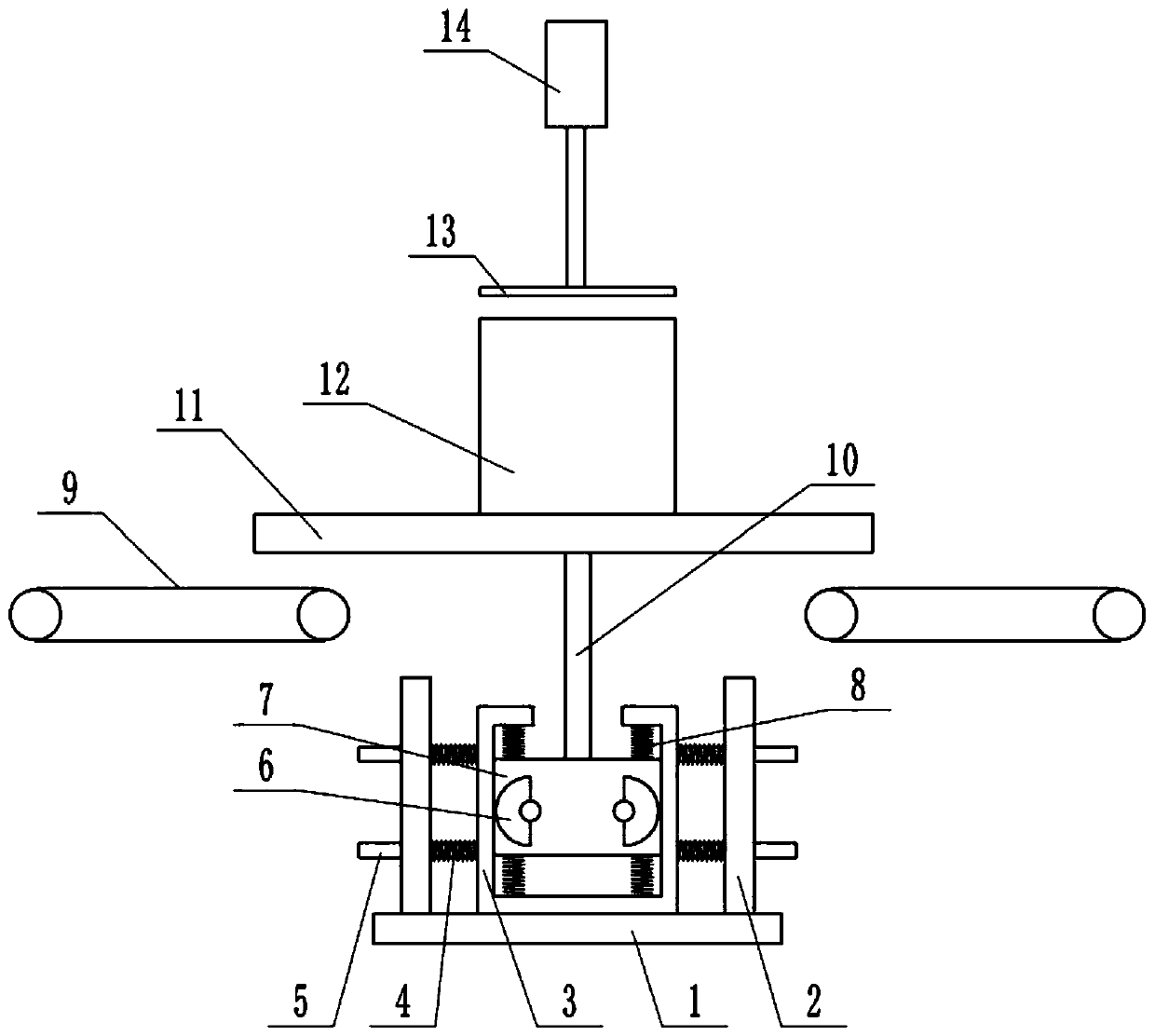

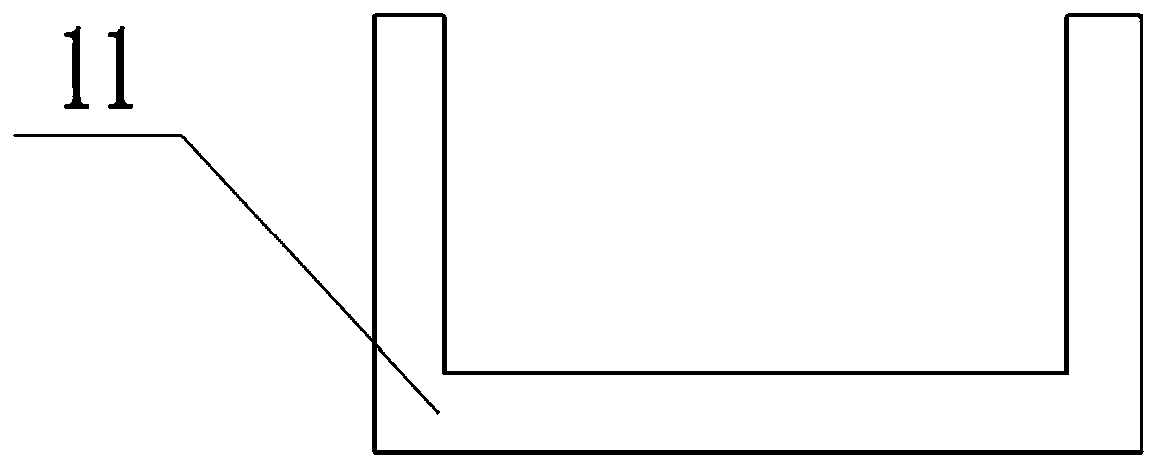

[0026] Basic as attached figure 1 Shown: the kneading mechanism used for tea finishing includes a frame, a kneading barrel 12 and a pressure plate 13, a cylinder 14 is fixed on the frame by screws, the cylinder rod of the cylinder 14 is welded to the pressure plate 13, and the kneading bucket 12 is fixed on the machine by screws On the frame, the pressure plate 13 is opposite to the top of the kneading bucket 12, and the pressure plate 13 can enter in the kneading bucket 12 under the expansion and contraction of the cylinder 14 to squeeze the tea leaves in the kneading bucket 12.

[0027] A base 1 is welded on the frame, and two vertical risers 2 are welded on the base 1 . A moving frame 3 is arranged between the two vertical plates 2, and the moving frame 3 is horizontally slidably connected to the base 1. Specifically, the bottom of the moving frame 3 is provided with a bump, and the base 1 is provided with a laterally arranged chute, and the bump located in the chute. Two...

Embodiment 2

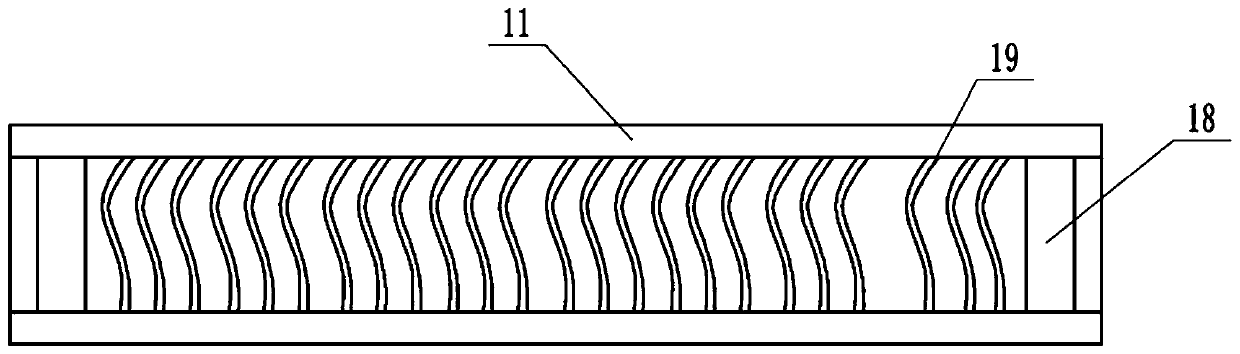

[0030] This embodiment continues to improve on the basis of Embodiment 1. The collection box 16 located on both sides of the vertical bar 10 is arranged under the kneading plate 11, and the collection box 16 is fixed on the frame by screws. combine Figure 5 As shown, the kneading plate 11 is provided with some filter holes, and the filter holes are opposite to the collection box 16. Vertical bar 10 is welded with the filter screen 17 that horizontally arranges, and the diameter of the mesh of filter screen 17 is less than the diameter of filter hole, and two collection boxes 16 are all provided with strip hole near the side of vertical bar 10, and filter screen 17 wears Through the strip hole, the filter screen 17 and the strip hole gap fit, because the filter screen 17 and the strip hole gap fit, when the vertical bar 10 drives the filter screen 17 to shake like this, the strip hole can not hinder the filter screen 17 from shaking. In addition, the frame is welded with a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com