Parallel platform for fruit and vegetable picking manipulator

A manipulator and parallel technology, applied in the direction of picking machines, manipulators, program-controlled manipulators, etc., to achieve a high degree of automation, reduce leakage rate and breakage rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

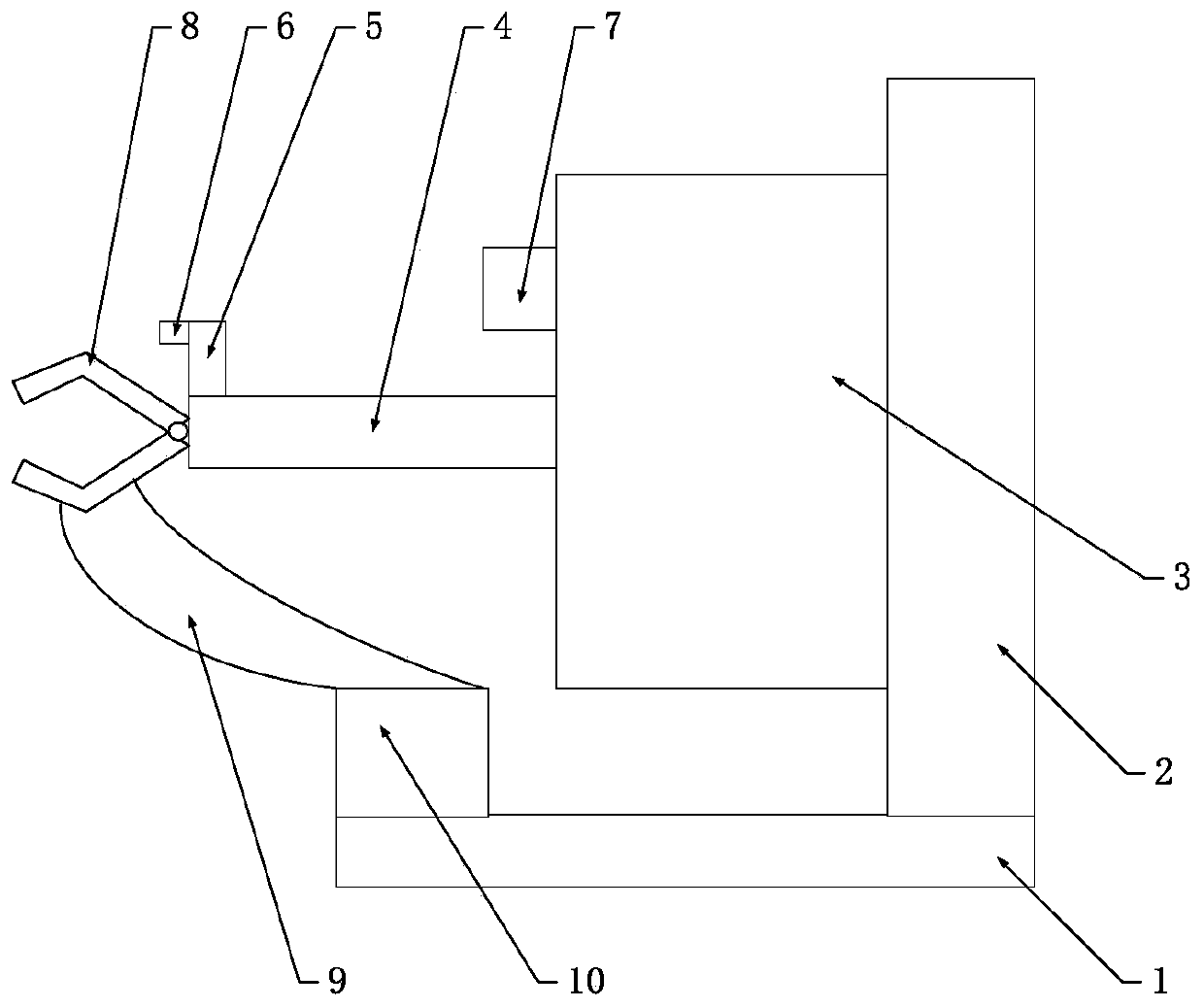

[0033] Parallel platform for fruit and vegetable picking manipulators, such as figure 1 As shown, the fruit and vegetable picking manipulator includes a base, a support rod, a parallel platform, a connecting arm, a camera mounting seat, a camera, an air pump, an end effector, a hose, and a recovery fruit basket. The machine base is located at the bottom, and the fruit and vegetable picking manipulator can be fixed to a mobile carrier such as a vehicle. The support plate is vertically fixed on the machine base. The parallel platform is fixed at the front end of the support plate. The connecting arm Fixed on the moving platform of the parallel platform, set horizontally, the camera mount is fixed above the front end of the connecting arm, the camera consists of 2 cameras, the optical axes of the two cameras are parallel, and the horizontal scanning lines of the two cameras Located on the same plane, they are all fixed on the front end of the camera mounting base for collecting t...

Embodiment 2

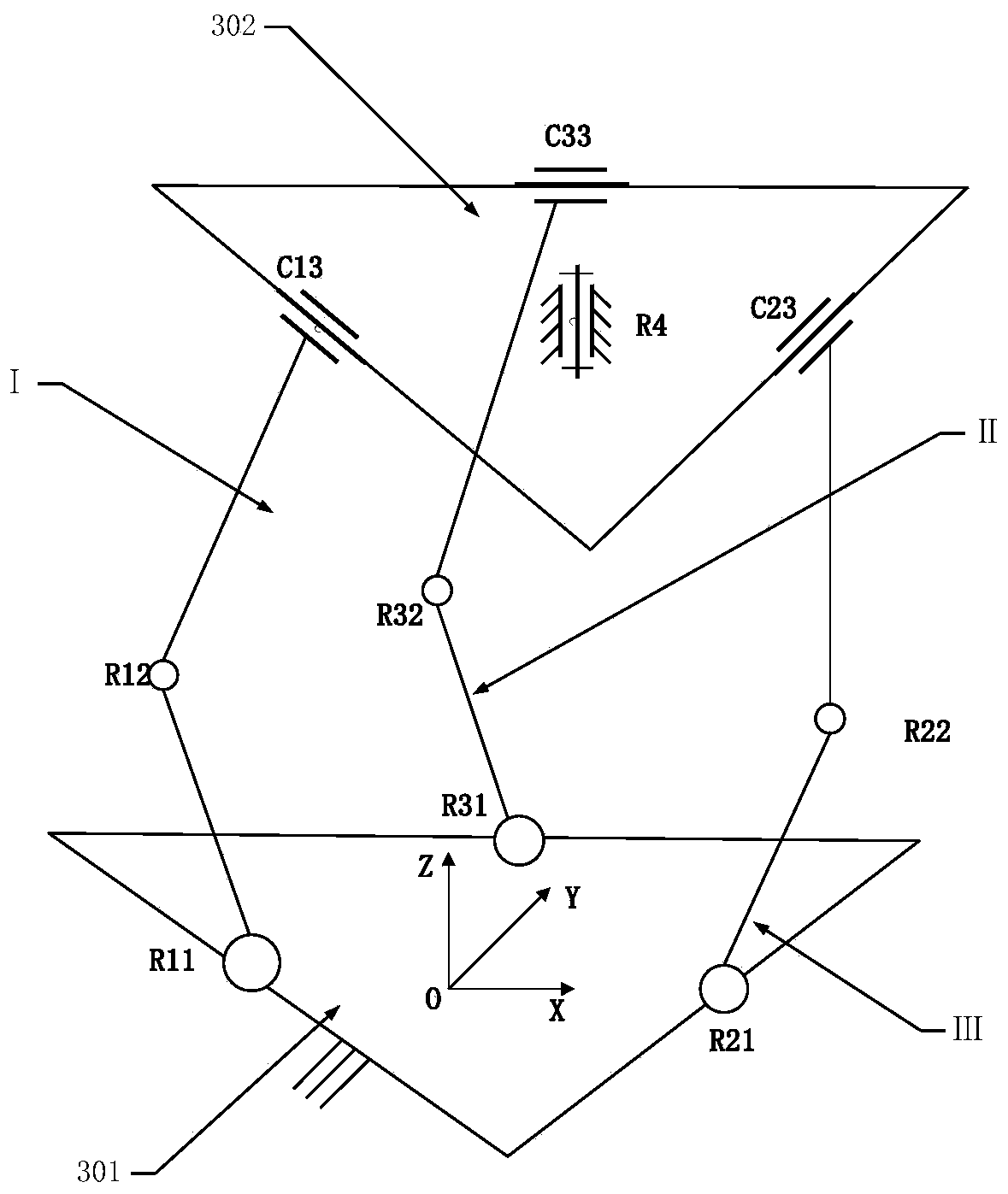

[0036] like figure 2 As shown, the parallel mechanism of the parallel platform has a total number of motion pairs m=10, and the number of components n=10. According to the degree of freedom (DOF) formula

[0037]

[0038]

[0039] Determine the degree of freedom (DOF) of the mechanism as F=4, and the four degrees of freedom are respectively translation along the X axis, Y axis, Z axis and rotation along the Z axis;

[0040] For a mechanism with a degree of freedom F, preselect F kinematic pairs as driving pairs and stiffen them. If the obtained new mechanism degree of freedom F’=0, then the preselected F kinematic pairs can be driving pairs at the same time. Since the degree of freedom of the mechanism is 4, the rotating pair R11, R21, R31 of the three branches and the rotating pair R4 on the moving platform are selected as the driving pair, and they are stiffened to obtain the degree of freedom of the stiffened mechanism F'=0, Meets drive side presence criteria.

Embodiment 3

[0042] The end effector of the fruit and vegetable picking manipulator, such as image 3 As shown, it includes connecting plate, air cylinder, suction pipe, gripper, rubber pad, and cutting knife. The connecting plate is located at the rearmost end of the end effector for fixing the end effector on the connecting arm. On the central axis of the end effector, it is connected with the air pump pipeline, which is used to provide gripping and loosening of the gripper. The gripper has two upper and lower grippers in total, and the rear ends of the two grippers are connected by pin shafts, and are fixed on the cylinder together. On the guide rail, when the cylinder moves backward, the two claws move toward the central axis to realize the grasping function. When the cylinder moves, the two claws move away from the central axis to realize the relaxation function. The suction pipe is fixed on the central axis of the rear ends of the two claws , connected with the air pump pipeline, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com