Full-automatic carton sealing machine structure and carton sealing method

A case sealer, fully automatic technology for packaging sealing/fastening, external support, transport packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

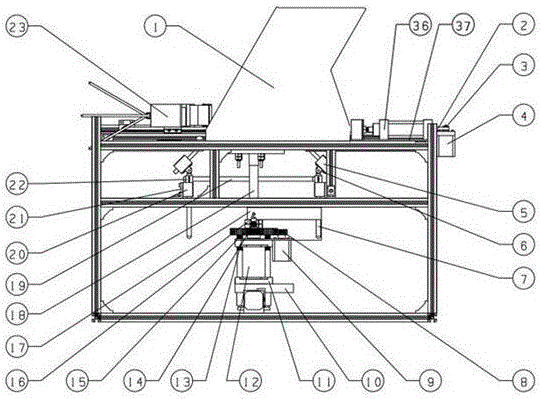

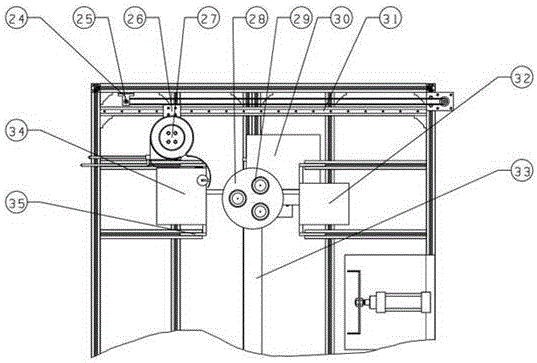

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0032] The invention provides a fully automatic box sealing machine structure, which can solve the defects of the existing large-scale assembly line carton packaging machinery that occupy a large area, expensive equipment and maintenance costs, complex structure and operation, and poor start-stop flexibility. The comprehensive benefit optimization of volume, cost and efficiency.

[0033] As an embodiment of the present invention, the present invention provides such as figure 1 and figure 2The structure of a fully automatic box sealing machine shown includes a box taking device, a cylinder device, an inclined-plane turntable mechanism, a push rod turnover mechanism, and a sealing mechanism. The box taking device includes a header barrel 1 and an elastic pressure plate 23. The elastic pressure plate 23 is on the side of the header barrel 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com