Surface consistency packaging LED display unit based on mold pressing technology

A display unit and consistency technology, applied in electrical components, identification devices, instruments, etc., can solve problems such as difficulties in mass production, poor surface consistency of LED displays, and poor ink color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

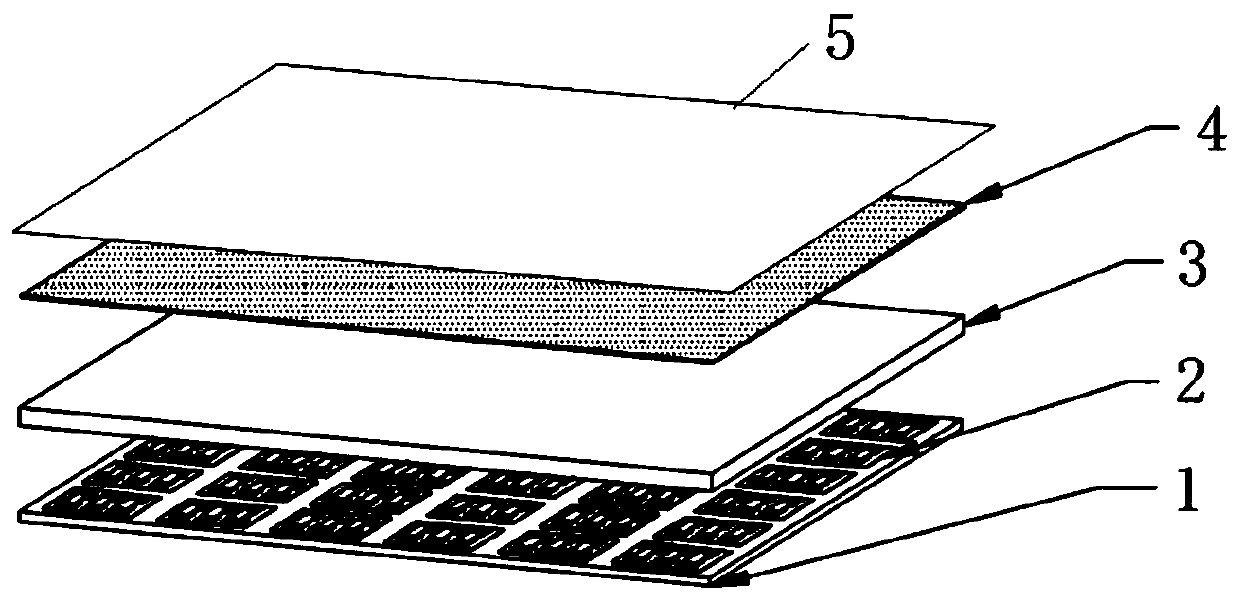

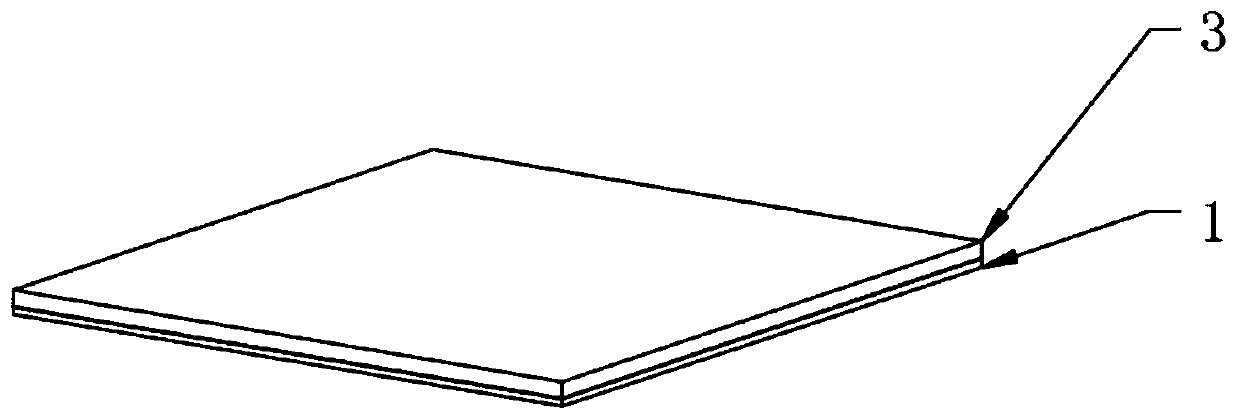

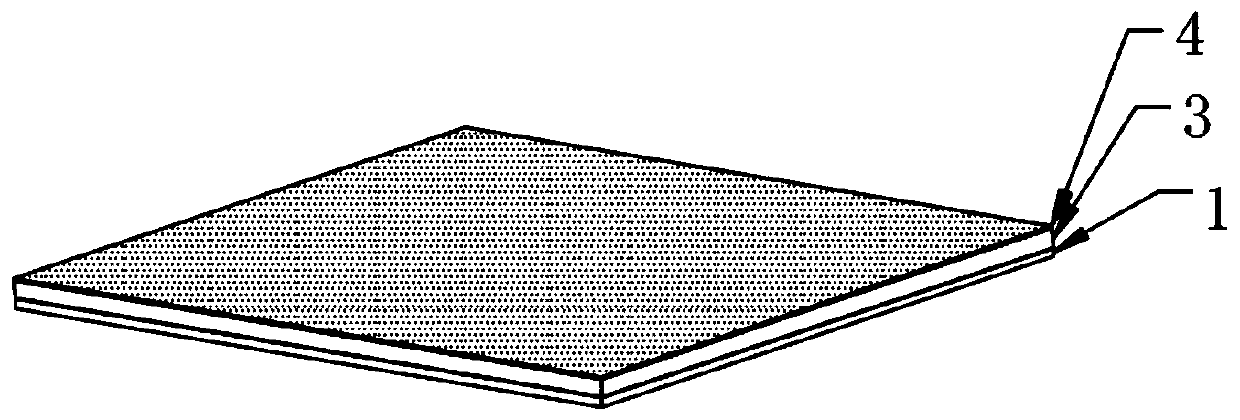

[0025] Such as figure 1 As shown, the surface consistent packaging LED display unit based on molding technology of the present invention includes a circuit board 1 with LED light-emitting chips 2 fixed thereon, a first packaging adhesive layer 3, a second packaging adhesive layer 4, and a release film layer 5; The first encapsulation adhesive layer 3 is prepared on the surface of the circuit board 1 with the LED light emitting chip fixed thereon, the second encapsulation adhesive layer 4 is prepared on the first encapsulation adhesive layer 3 , and the release film layer 5 is pressed on the second encapsulation adhesive layer 4 surface; the first encapsulation adhesive layer 3 is an epoxy resin AB adhesive layer mixed with 10% to 60% by weight scattering agent, and its thickness is 0.15-0.3mm; the second encapsulation adhesive layer 4 is mixed with 10% to 60% % weight ratio of scattering agent and 3-10‰ amount ratio of epoxy resin adhesive layer of melanin, the thickness of wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com