Projector calibration method based on Gold matrix projection

A calibration method and technology of projectors, which are applied in the directions of instruments, image analysis, image enhancement, etc., can solve problems affecting calibration accuracy, etc., and achieve the effect of simple calibration, simplified difficulty, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. But it should not limit the protection scope of the present invention.

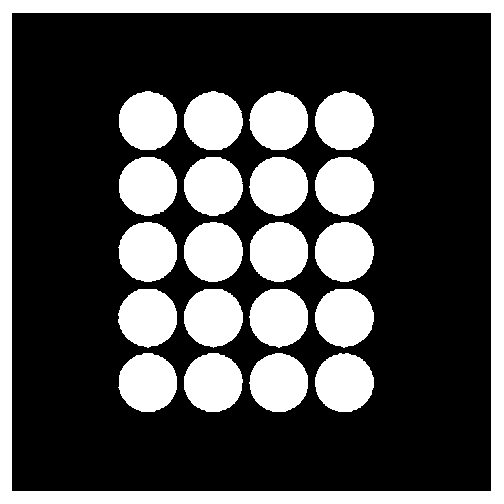

[0041] Since both the calibration plate and the projection pattern in this embodiment are circular arrays, in order to distinguish, the circles on the calibration plate are called big circles, and the circles projecting the Gold matrix are called small circles.

[0042] In this embodiment, the camera is a color area array camera with a model number of FL3-U3-20E4CUSB3.0 interface of Pointgrey Company, with a resolution of 1600×1200 pixel and a pixel size of 4.5um×4.5um. The projector adopts the model of LCD projector produced by EPSON Company, and the resolution is 1920×1080pixel. The structure of the equipment used in the fast three-dimensional measurement method for large-size optical blanks in the present invention is as follows: figure 1 shown.

[0043] The calibration method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com