A test device and test method for the bearing capacity of a mining steel strip

A bearing capacity and testing device technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problem of not being able to truly simulate the stress of the steel strip, unable to truly reflect the deformation and damage of the steel strip, Difficulty testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

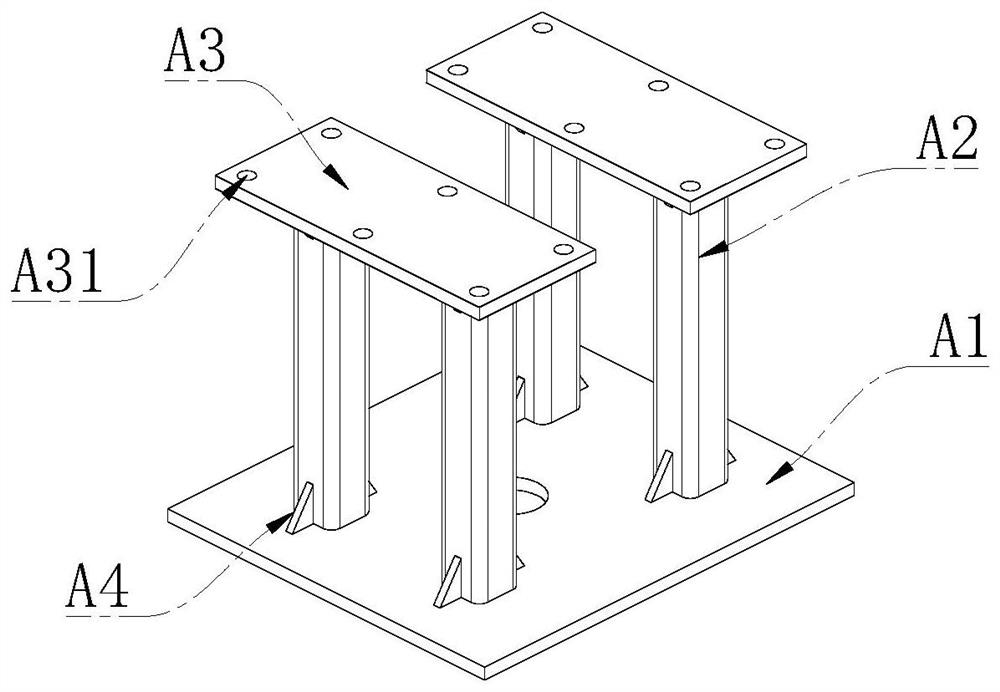

[0047] like Figure 1 to Figure 10 As shown, the present invention provides a mining steel strip bearing capacity testing device, comprising a loading frame B, a tested steel strip assembly D, a box body C and a base A arranged vertically from top to bottom;

[0048] The base A includes a base plate A1, two pairs of columns A2 fixedly connected to the upper part of the base plate A1 along the length direction, two connecting plates A3 respectively fixedly connected to the upper ends of the two pairs of columns A2 and a base bolt group composed of a plurality of bolts A5; the connecting plate A3 is provided with a connecting plate hole A31 for the base bolts in the base bolt group A5 to pass through;

[0049] The loading frame B includes an upper loading beam B1, a lower loading beam B2 and two loading columns B11, and the upper loading beam B1 and the lower loading beam B2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com