Aerated concrete composite thermal insulation wallboard system and construction method thereof

An aerated concrete and composite thermal insulation technology, applied in thermal insulation, walls, building components, etc., can solve the problems of damage to plate cutting equipment, long production cycle of wall panels, low production efficiency, etc., to reduce production costs and shorten factory production. Cycle time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

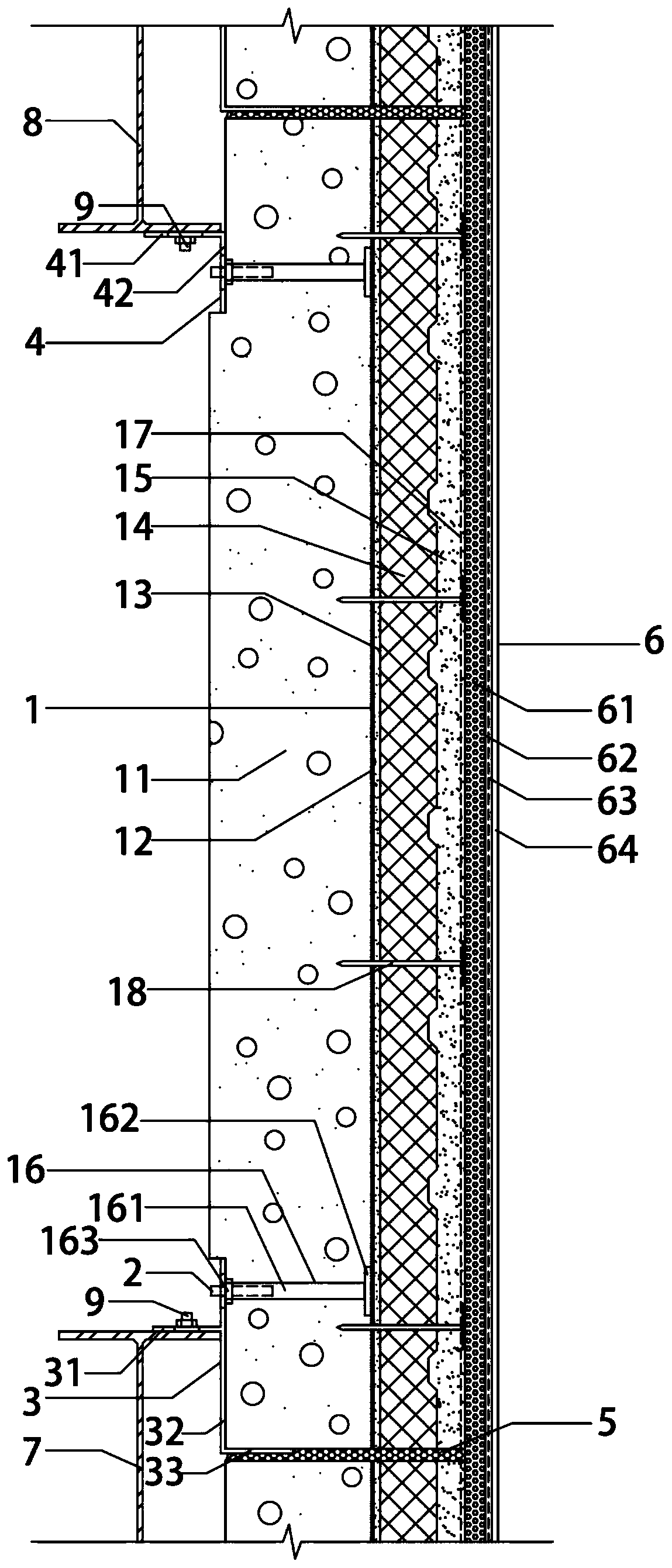

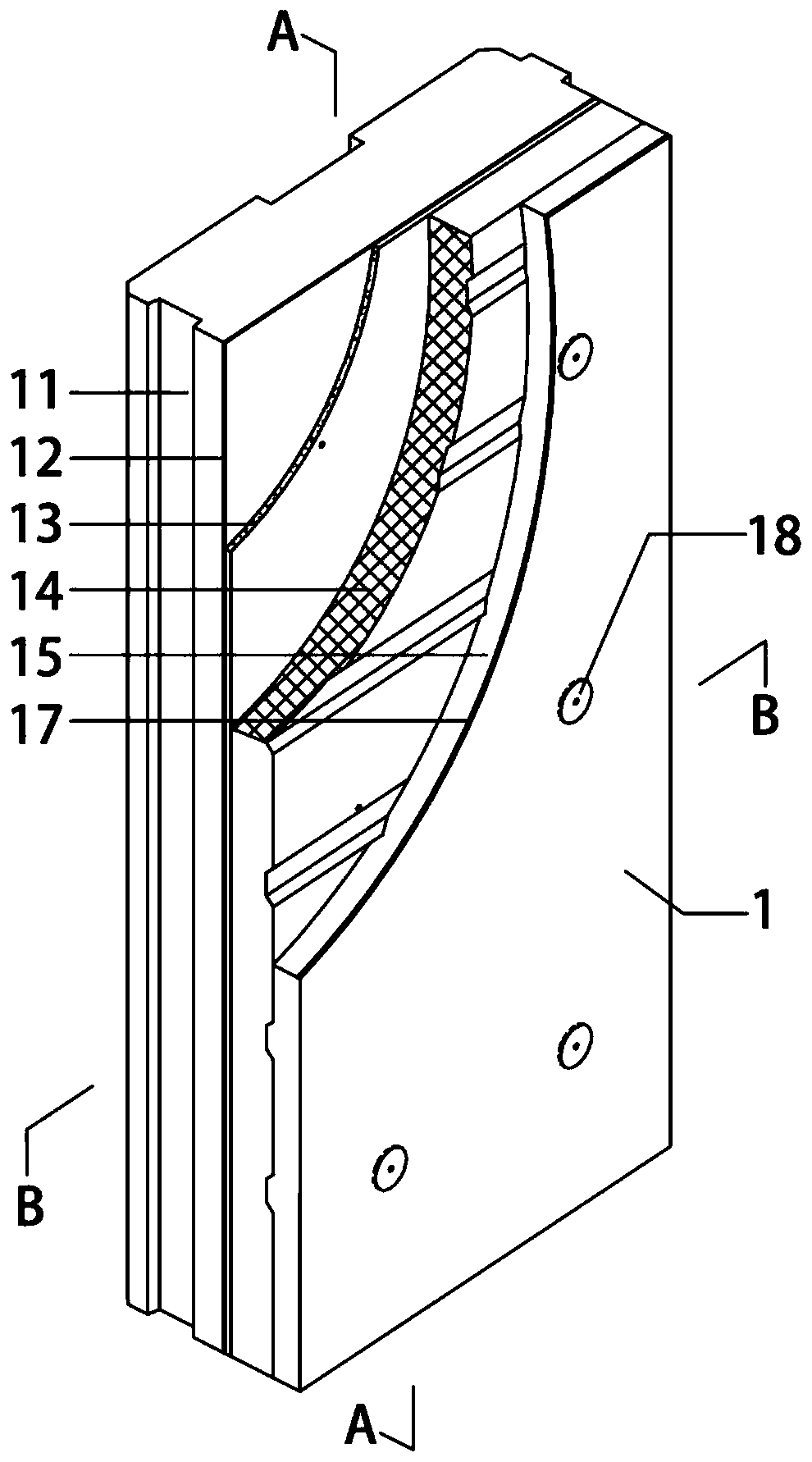

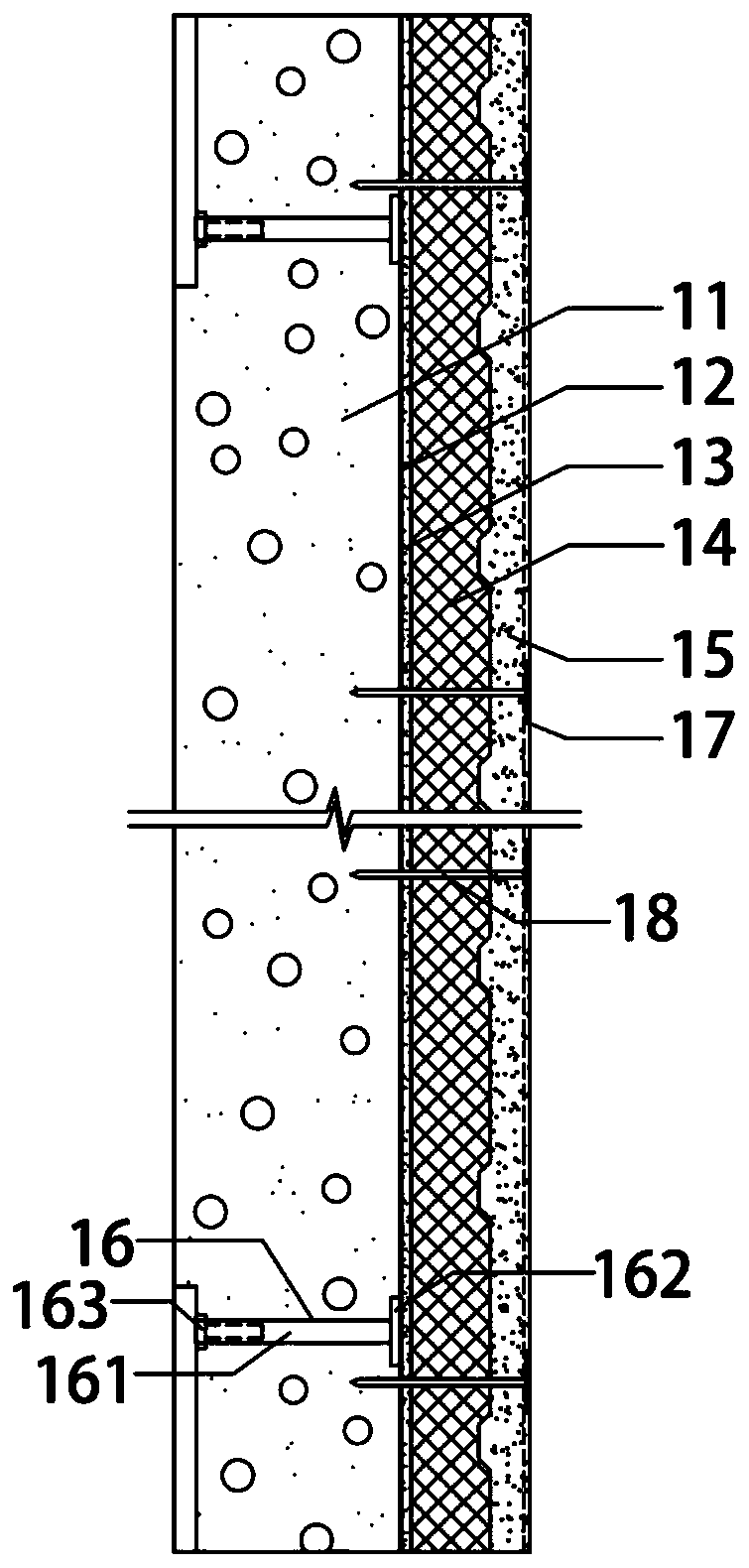

[0038] Such as figure 1 As shown, the aerated concrete composite thermal insulation wall panel system is used for prefabricated steel structure buildings, including: aerated concrete composite thermal insulation strips 1, connecting bolts 2, supporting parts 3, tie parts 4, caulking materials 5, Wall leveling and finishing system 6, wherein the lower end of the aerated concrete composite thermal insulation strip 1 is connected to the lower frame steel beam 7 through the connecting bolt 2 and the supporting member 3, and the upper end of the aerated concrete composite thermal insulation strip 1 is connected through the connecting bolt 2, The anchors 4 are connected to the upper frame steel beams 8 .

[0039] The height of the aerated concrete composite thermal insulation strip 1 is the distance between the upper and lower adjacent two-story frame beams, and the width is the standard width of the aerated concrete composite thermal insulation strip 1; the left and right adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com