Asphalt pavement in-place hot recycling harrowing plow-shaped harrow tooth device and application of device in harrowing paving vehicle

A technology of asphalt pavement and rake teeth, which is used in automatic rake adjustment of depth and leveling functions. It can solve problems such as wear of the integrated cutter head, achieve good practicability and economy, improve economic performance, and reduce use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

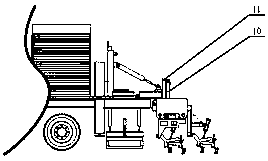

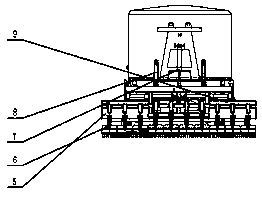

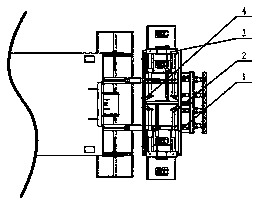

[0025] A plow-shaped rake tooth device for in-situ thermal regeneration of asphalt pavement, comprising correspondingly arranged raking frames 1 5 and 9 The horizontal distance between them is provided with a corresponding vertical drive device to adjust the longitudinal height and raking depth of raking frame one 5 and raking frame two 9;

[0026] The first rake frame 5 and the second rake frame 9 all include a rake tooth unit 61 for raking, and the rake tooth unit 61 is arranged on the first rake frame 5 and the second rake frame by an elastic adjustment mechanism. 9 on.

[0027] The horizontal driving device includes a telescopic oil cylinder 10, and a sliding shaft 2 driven by the telescopic oil cylinder 10 to drive the first raking frame 1 and the second raking frame 9 to move horizontally.

[0028] The vertical driving device includes a lifting main oil cylinder 7 for driving the first 5 raking frame and the second 9 raking frame, and the height adjustment for adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com