Waste brick regenerated ultrahigh-toughness mixture as well as preparation method and application thereof

A technology of ultra-high toughness and discarded bricks, applied in the direction of climate change adaptation, etc., can solve the problem of less fine aggregate, achieve the effects of reducing quantity and width, reducing energy consumption, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

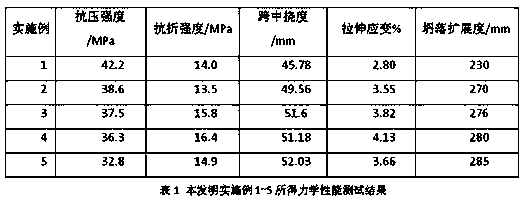

Examples

Embodiment 1

[0049] (1) Crushing the waste sintered bricks, ball milling the coarse aggregate of recycled bricks obtained after crushing for 15~20min, and sieving the fine aggregate particles of recycled bricks, the fine aggregate particles are less than or equal to 0.3mm, put into Oven drying;

[0050] (2) Take 1350g of recycled brick fine aggregate, and measure the additional water content of recycled mortar according to GB / T 25176-2010; obtain the additional water demand of recycled brick fine aggregate;

[0051] (3) Prepare water, cement, fly ash, recycled brick fine aggregate, polyvinyl alcohol fiber, water reducer, thickener according to the mix ratio 1: 1.64: 0.89: 0.76: 0.04: 0.002: 0.002;

[0052] (4) Pre-wet the mixer cylinder, then put cement, fly ash, and recycled brick fine aggregate into the mixer in turn, and stir for 2~3 minutes to make the three materials mix evenly;

[0053] (5) Mix the water and the water reducer first, stir and mix evenly, then add to the mixer, and st...

Embodiment 2

[0057] (1) Crushing the waste sintered bricks, ball milling the coarse aggregate of recycled bricks obtained after crushing for 15~20min, and sieving the fine aggregate particles of recycled bricks, the fine aggregate particles are less than or equal to 0.3mm, put into Oven drying;

[0058] (2) Take 1350g of recycled brick fine aggregate, and measure the additional water content of recycled mortar according to GB / T 25176-2010; obtain the additional water demand of recycled brick fine aggregate;

[0059] (3) Prepare water, cement, fly ash, recycled brick fine aggregate, polyvinyl alcohol fiber, water reducer, thickener according to the mix ratio 1: 1.46: 0.80: 0.76: 0.04: 0.002: 0.002;

[0060] (4) Pre-wet the mixer cylinder, then put cement, fly ash, and recycled brick fine aggregate into the mixer in turn, and stir for 2~3 minutes to make the three materials mix evenly;

[0061] (5) Mix the water and the water reducer first, stir and mix evenly, then add to the mixer, and st...

Embodiment 3

[0065] (1) Crushing the waste sintered bricks, ball milling the coarse aggregate of recycled bricks obtained after crushing for 15~20min, and sieving the fine aggregate particles of recycled bricks, the fine aggregate particles are less than or equal to 0.3mm, put into Oven drying;

[0066] (2) Take 1350g of recycled brick fine aggregate, and measure the additional water content of recycled mortar according to GB / T 25176-2010; obtain the additional water demand of recycled brick fine aggregate;

[0067] (3) Prepare water, cement, fly ash, recycled brick fine aggregate, polyvinyl alcohol fiber, water reducer, thickener according to the mix ratio 1: 1.41: 0.76: 0.76: 0.04: 0.002: 0.002;

[0068] (4) Pre-wet the mixer cylinder, then put cement, fly ash, and recycled brick fine aggregate into the mixer in turn, and stir for 2~3 minutes to make the three materials mix evenly;

[0069] (5) Mix the water and the water reducer first, stir and mix evenly, then add to the mixer, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com