A non-destructive paper feeding device and method for a certificate making machine

A technology of certificate making machine and control device, which is applied in the direction of transportation and packaging, thin material processing, and sending objects, etc., which can solve the problems that the integrity of blank certificate cores cannot be guaranteed, and achieve the effect of avoiding bending and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

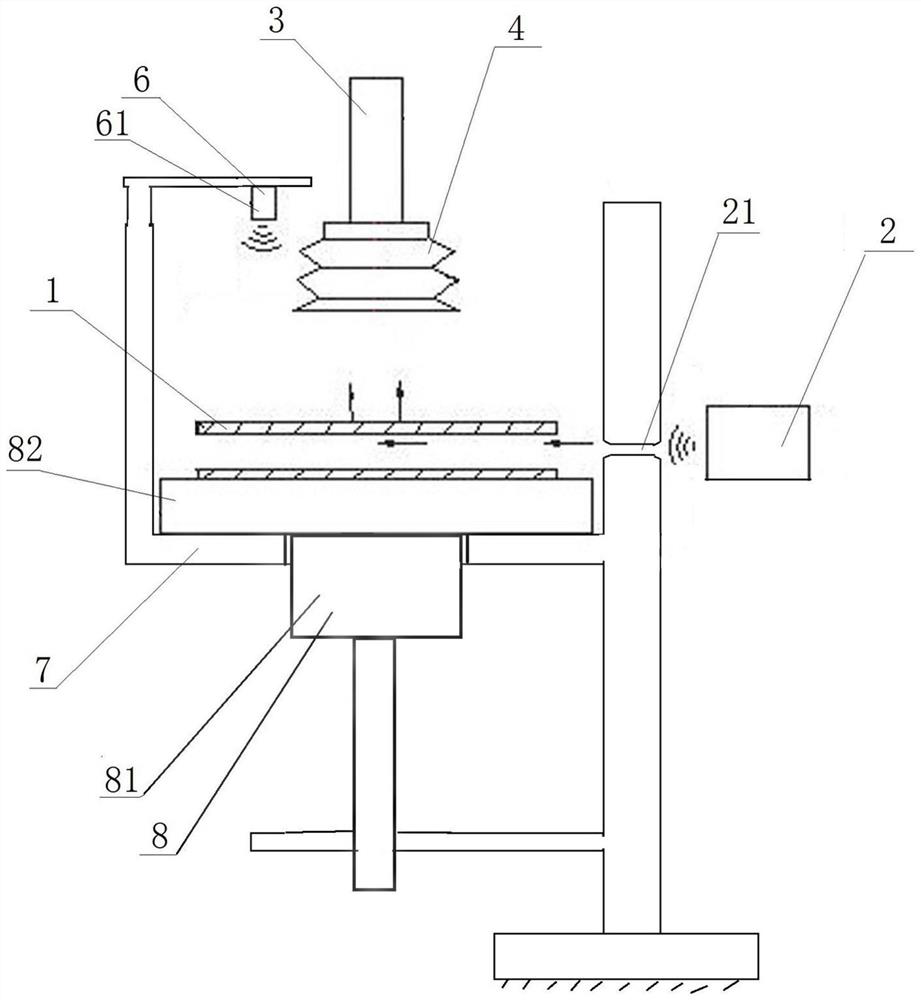

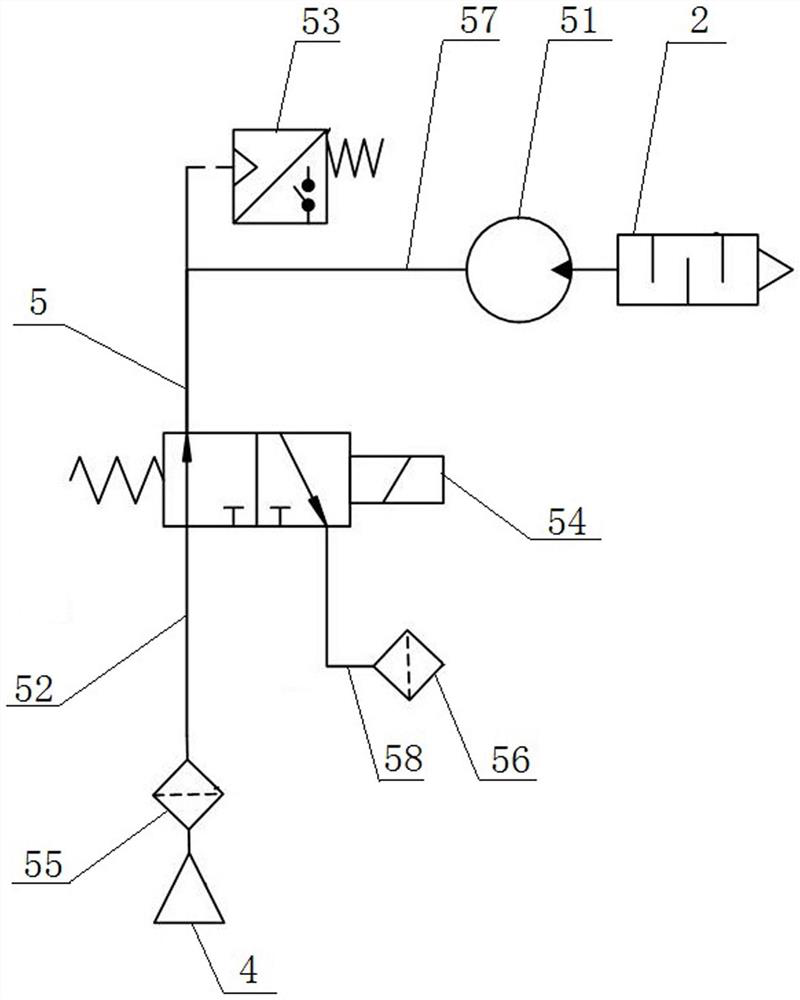

[0040] A non-destructive paper feeding device for a certificate making machine, combining Figure 1 to Figure 2 As shown, it includes a main controller, a sorting manipulator 3 , a suction cup 4 , a support frame 7 , a stacking platform 82 for blank certificate cores, a high-pressure blower mechanism 2 , a jacking mechanism 8 and a suction cup control system 5 .

[0041] The main controller is used to control the overall operation of the device, and the main controller in the present invention adopts a PLC programmable controller.

[0042] The sorting manipulator 3 is used to move under the control of the main controller, and can move forward, backward, left, right, up and down under the control of the main controller. The controlled end of the sorting manipulator 3 is connected to the main controller. output.

[0043] The suction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com