Pulverized coal bunker provided with discharging and weighing device and feeding fluidization system

A weighing device and pulverized coal bunker technology, applied in the field of pulverized coal bins, can solve the problems of eddy current return pulverized coal weighing, inability to provide fuel stably, poor fluidization, etc., to facilitate material flow and injection The effect is uniform and effective, and the effect of improving the activity of lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

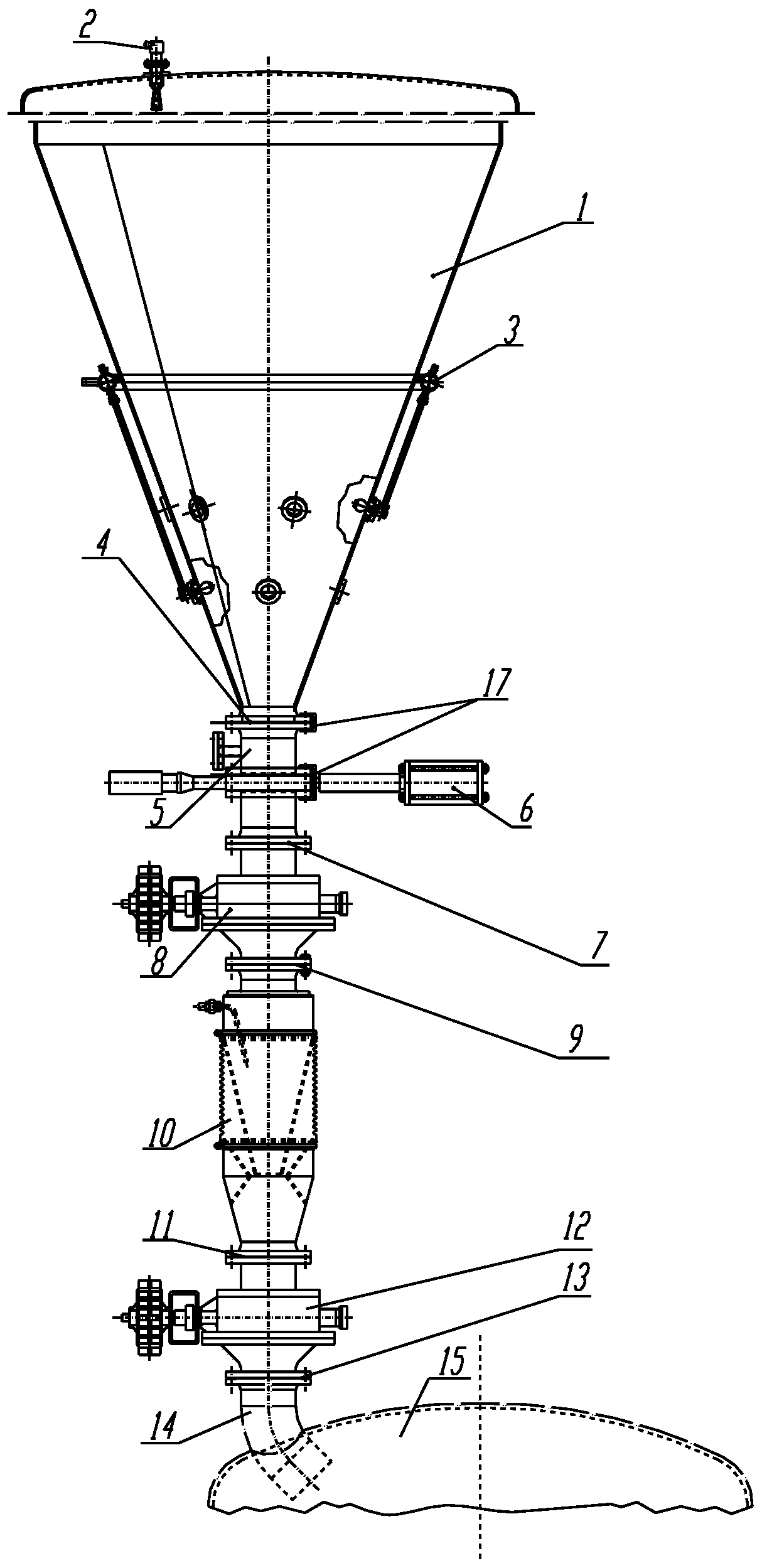

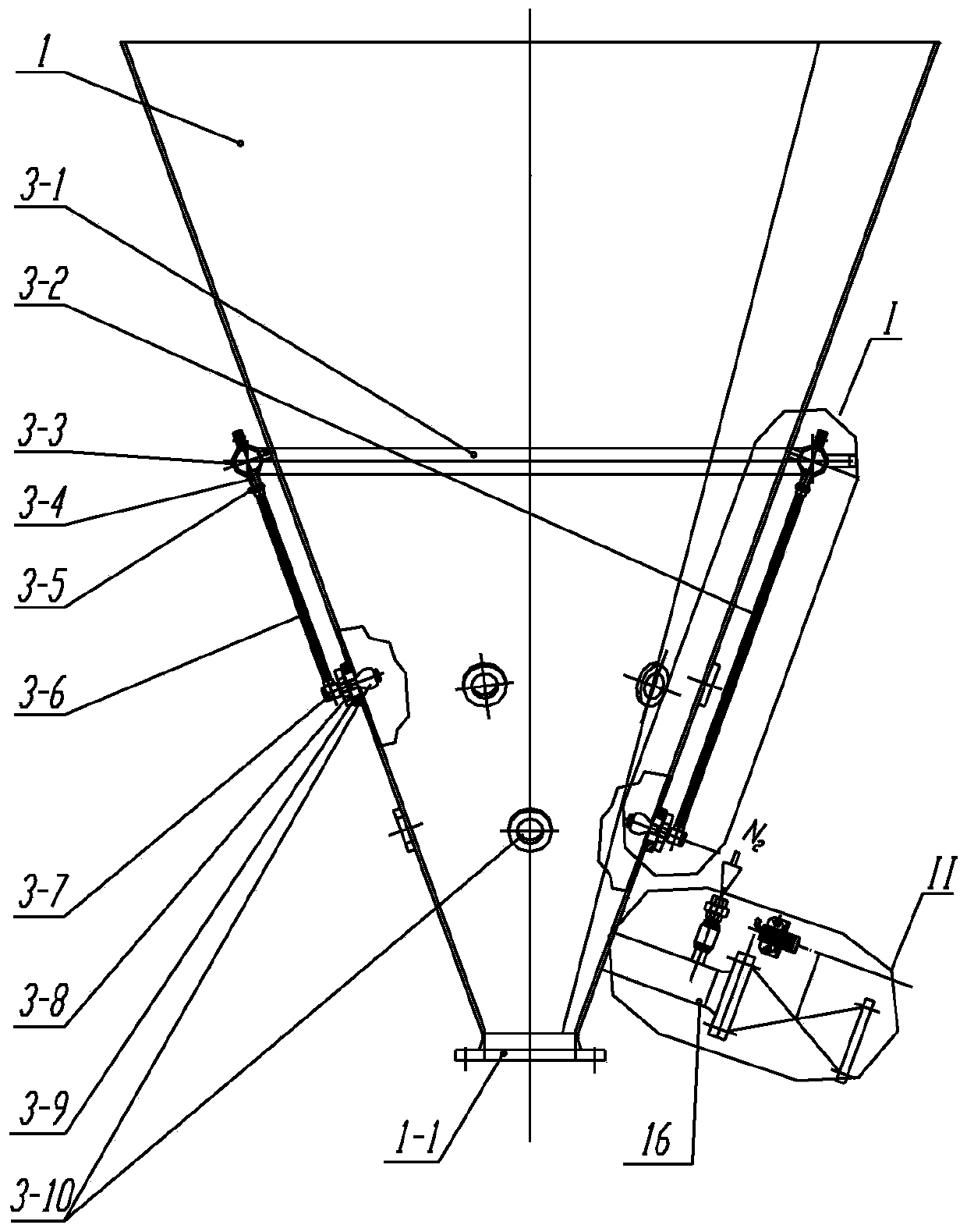

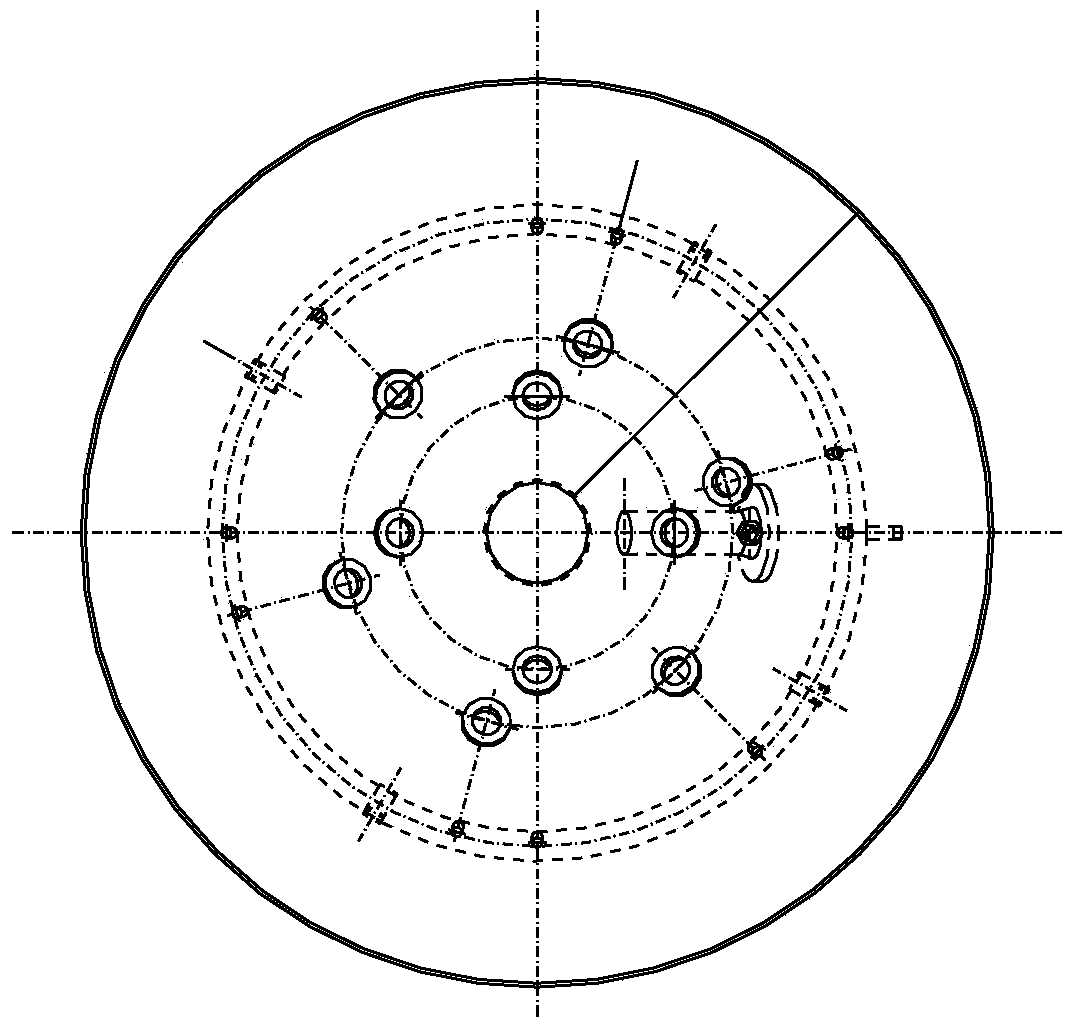

[0034] Such as figure 1As shown, a pulverized coal bunker configured with a discharge and weighing device and a feed fluidization system according to the present invention includes a pulverized coal bunker. Pulverized coal outlet 1-1; also includes annular injection gas supply device 3, fluidization device 10 and powder weighing device 15; said conical hopper 1 is provided with annular injection gas supply device 3 and inlet pipeline 16; The pulverized coal discharge port 1-1 is sequentially connected to the pneumatic gate valve 6, the electric cut-off sealing valve 1 8, the fluidization device 10, the electric cut-off sealing valve 2 12 and the powder weighing device 15, and the pulverized coal discharge port 1 Between -1 and the pneumatic gate valve 6, between the pneumatic gate valve 6 and the electric cut-off sealing valve 8, between the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com