Protective device used for heavy truck cab assembly welding

A protection device, cab technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of human body impact, unimaginable consequences, affecting the working environment, etc., to ensure normal service life, avoid collision damage, and avoid everywhere. splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

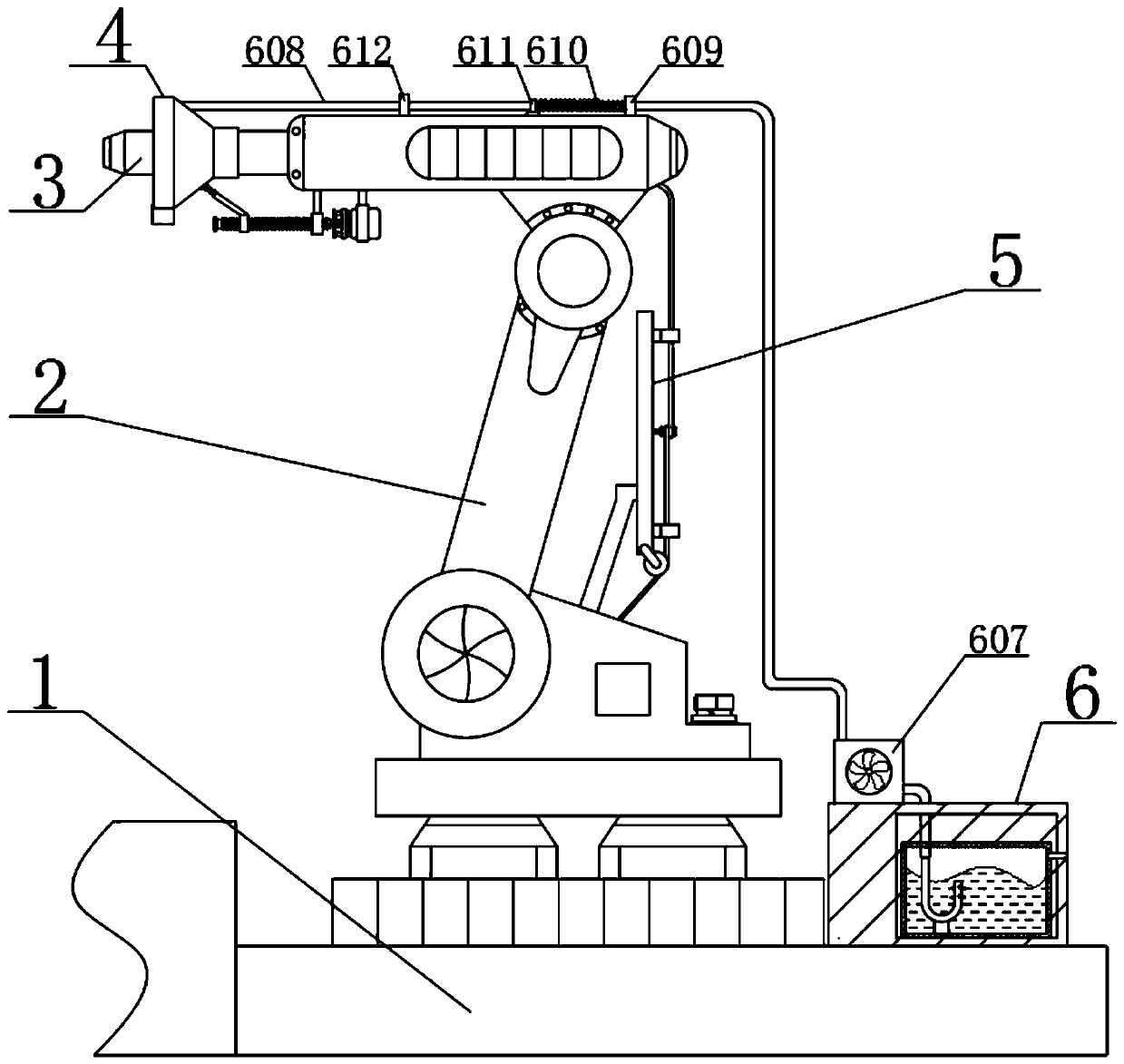

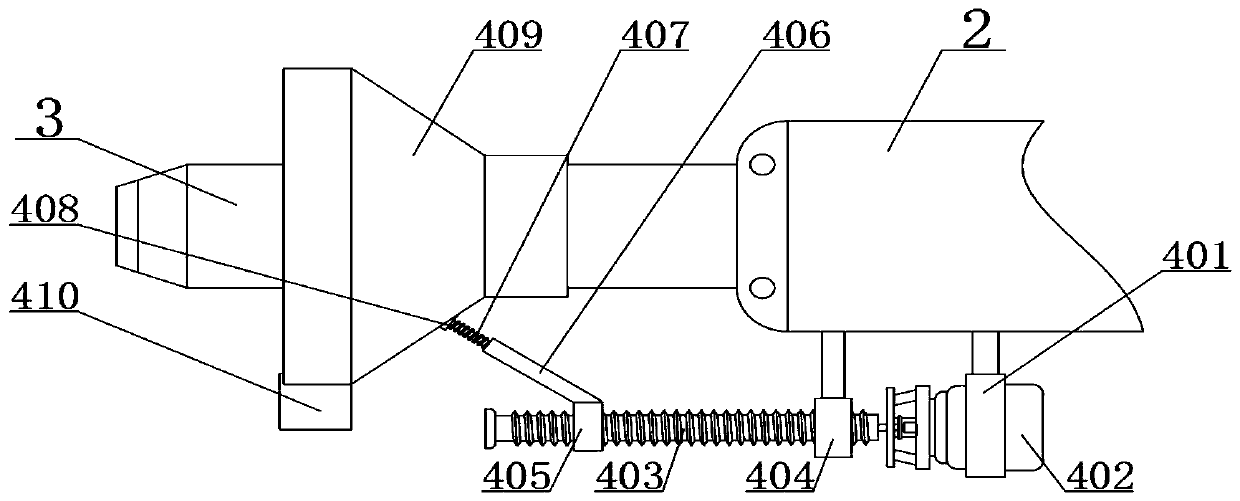

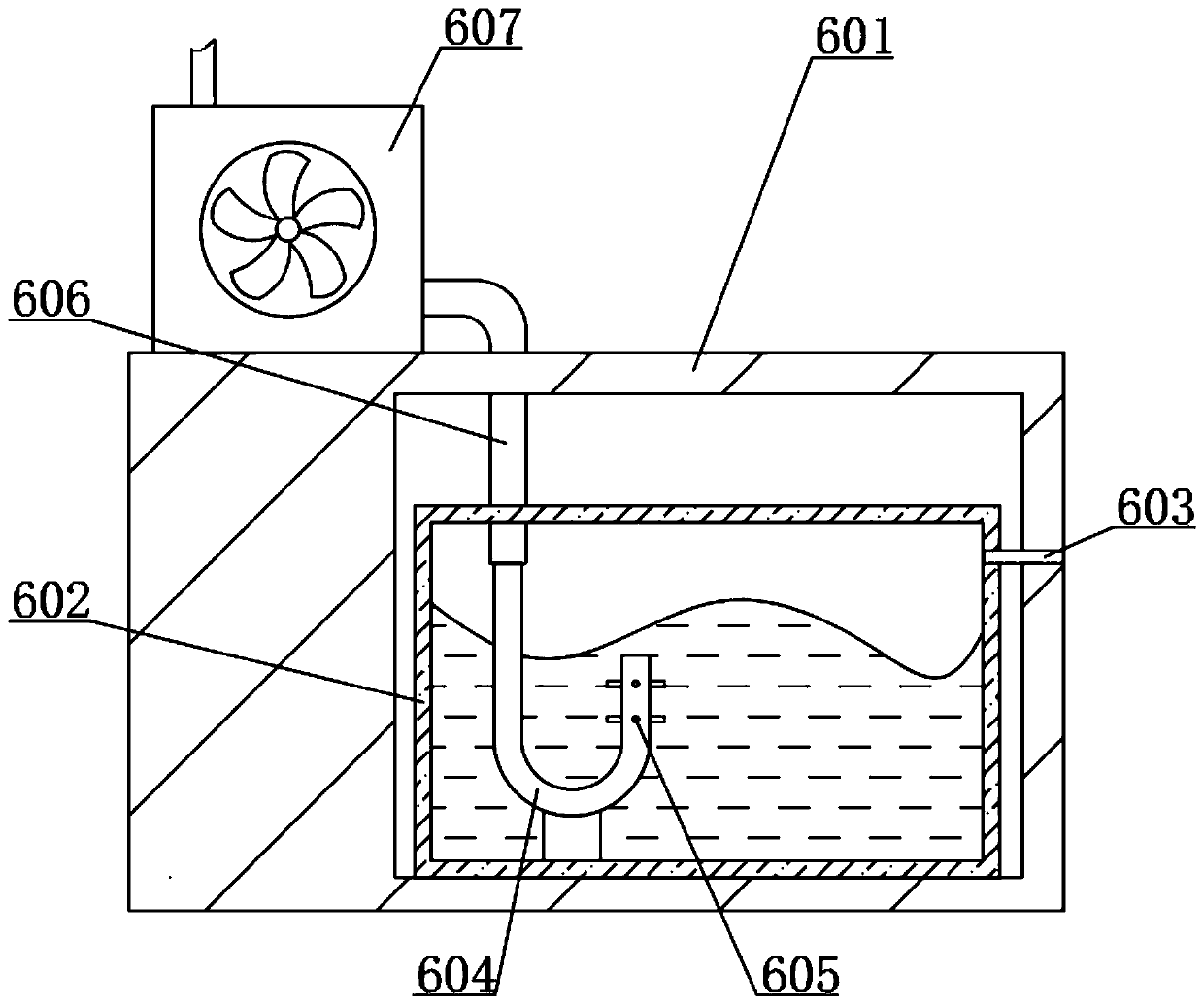

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0027]A protection device for heavy truck cab assembly welding, including a base 1, a welding robot arm 2 and a welding head 3, the upper end surface of the base 1 is fixedly connected with a welding robot arm 2 and an exhaust gas treatment device 6 distributed left and right, and the welding robot arm 2 The left end face is fixedly connected with a welding head 3, and the outer side of the welding head 3 is slidingly connected with a protective device 4. The protective device 4 includes a fixed frame 401, a rotating motor 402, a threaded rod 403 and a support frame 404, and the upper end of the fixed frame 401 is fixedly connected with a welding machine. The arm 2 is fixedly connected with a rotating motor 402 below the fixed frame 401. The rotating motor 402 provides power for the rotation of the screw rod 403. The end of the main sha...

Embodiment 2

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0032]A protection device for heavy truck cab assembly welding, including a base 1, a welding robot arm 2 and a welding head 3, the upper end surface of the base 1 is fixedly connected with a welding robot arm 2 and an exhaust gas treatment device 6 distributed left and right, and the welding robot arm 2 The left end face is fixedly connected with a welding head 3, and the outer side of the welding head 3 is slidingly connected with a protective device 4. The protective device 4 includes a fixed frame 401, a rotating motor 402, a threaded rod 403 and a support frame 404, and the upper end of the fixed frame 401 is fixedly connected with a welding machine. The arm 2 is fixedly connected with a rotating motor 402 below the fixed frame 401. The rotating motor 402 provides power for the rotation of the screw rod 403. The end of the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com