Automatic positioning device for battery cell tab

An automatic positioning and pole ear technology, applied in auxiliary devices, non-electric welding equipment, non-aqueous electrolyte batteries, etc., can solve the problems of low efficiency, large positioning deviation, poor flexibility, etc., to achieve high efficiency, alignment speed block, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

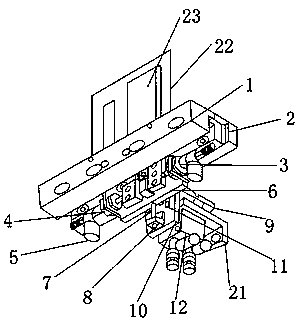

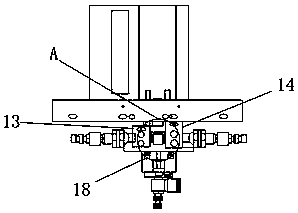

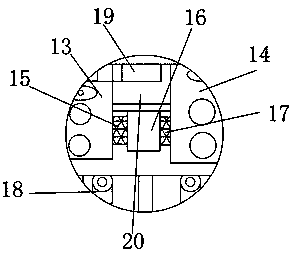

[0021] An embodiment of the present invention provides an automatic positioning device for battery tabs, such as Figure 1-3 As shown, it includes upper head 1, lower head 2, right clamping cylinder 3, left clamping cylinder 4, regulating valve 5, normalization fixing plate 6, forward and backward screw rod 7, fine-tuning block 8, up and down sliding plate 9, forward Reverse guide rail fixing plate 10, linear guide rail 11, upper and lower cylinder 12, left fixing clip 13, right fixing clip 14, left opening spring 15, spring support block 16, right opening spring 17, linear guide rail 18, right clip 19, left clip 20. The base 21, the aluminum plastic mold 22 and the bare cell 23, the rear end of the upper head 1 is flexibly connected with the lower head 2, the bottom of the right clamping cylinder 3 is fixedly connected with the front end of the inner wall of the lower head 2, and the bottom of the left clamping cylinder 4 It is fixedly connected with the front end of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com