A special non-silicon oil syringe for ophthalmology

A technology without silicone oil and syringes, applied in the field of medical devices, can solve problems such as poor sealing and sliding performance, inability to completely eliminate residues, and insufficient structure, and achieve high reliability, convenient processing, and reduced liquid residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific embodiments thereof will be described in detail below with reference to the accompanying drawings:

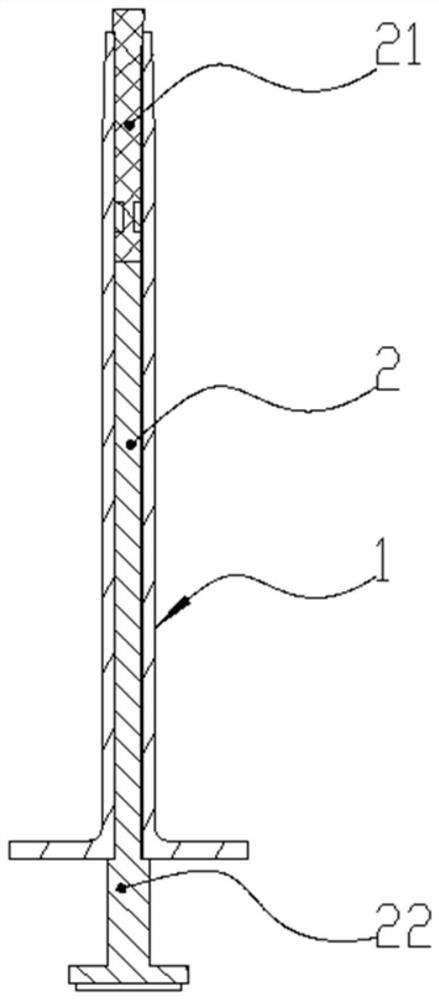

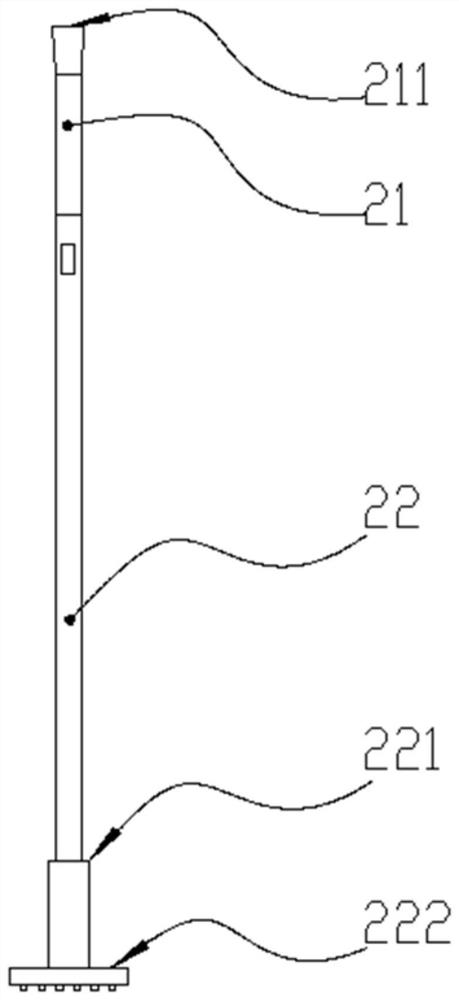

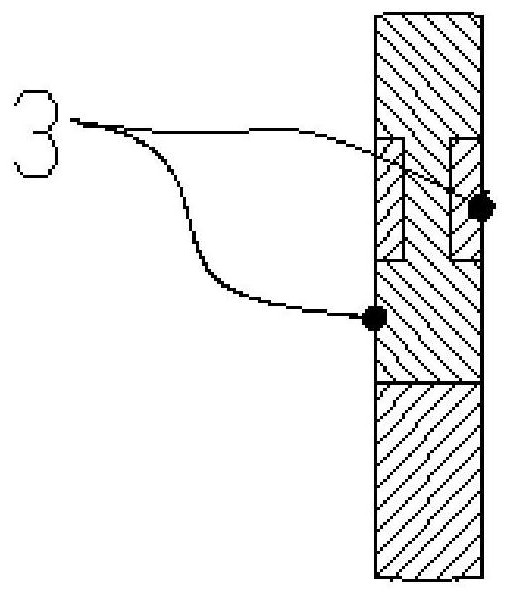

[0031] see Figure 1 to Figure 11 , the preferred embodiment of the present invention, a special silicone oil-free syringe for ophthalmology, comprising a jacket 1 and a core rod 2 inserted in it, the core rod 2 is divided into two sections, respectively the front section 21 of the core rod and the rear section of the core rod 22. The rear end of the front section 21 of the core rod and the front end of the rear section 22 of the core rod are connected together through the radial dovetail groove structure 3.

[0032] The elastic modulus of the front section 21 of the core rod is less than or equal to 600MPa, and the elastic modulus of the rear section 22 of the core rod is greater than or equal to 1 Gpa; the material used in the front section 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com