Insulating rod type wire clipper and using method thereof

A technology of bolt cutters and insulating rods, which is applied to cable installation devices, electrical components, equipment for cutting/splitting cables, etc., and can solve problems such as unreliable connection of clamp rods, inconvenient high-altitude operations, and backward equipment and technology , to achieve the effect of preventing the jaw from loosening and falling off, reliable connection mode and low working intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, below in conjunction with the accompanying drawings and specific embodiments, further elaborate how the present invention is implemented.

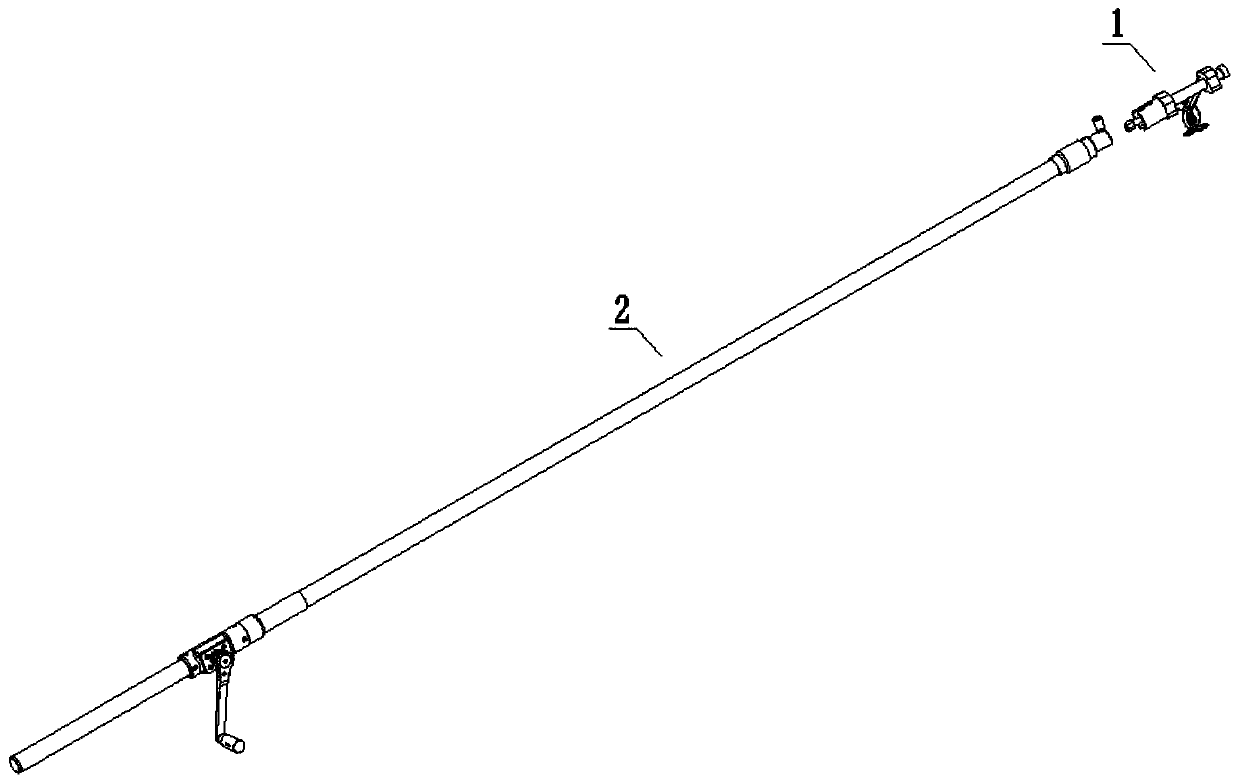

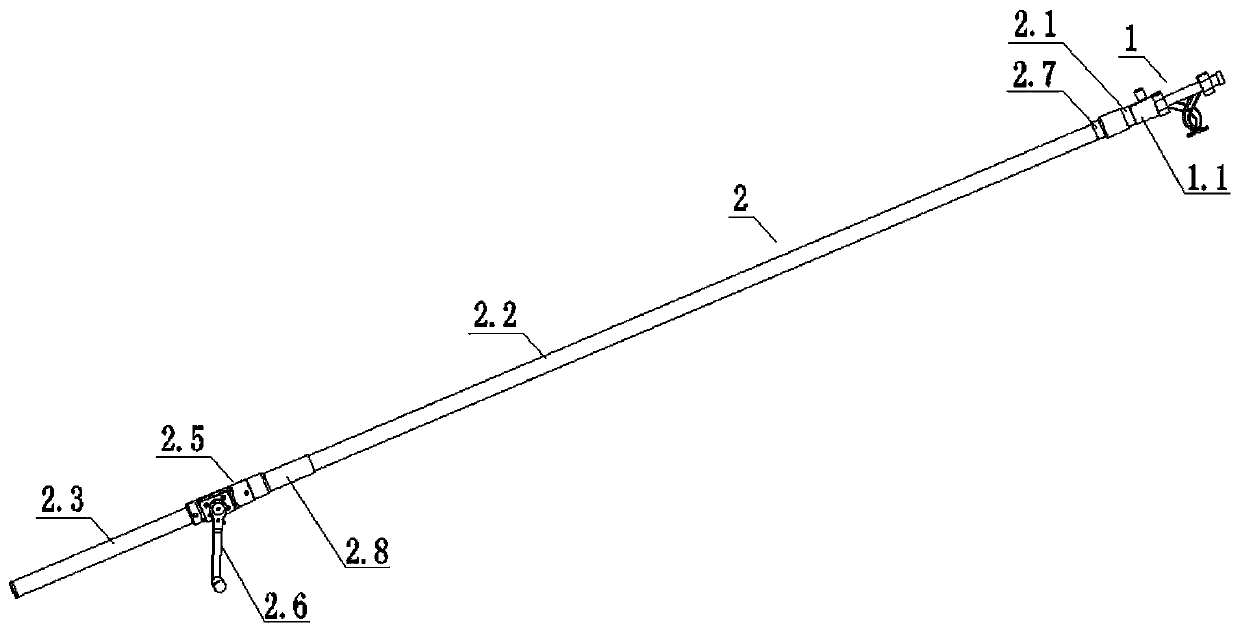

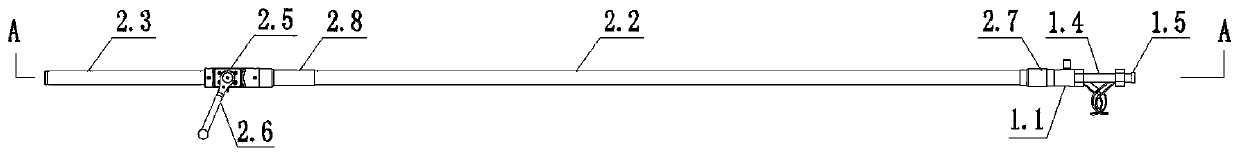

[0051] A kind of insulating rod type bolt cutter provided by the present invention, such as Figure 1 to Figure 2 As shown, including bolt cutter hardware 1 and insulated torsion crank lever 2, such as Figure 11 and Figure 12 As shown, the bolt cutter hardware 1 includes a push-in joint 1.1, an upper jaw transmission part 1.2, a lower jaw transmission part 1.3, a transmission bolt 1.4, and an anti-loosening nut 1.5. The stripping nut 1.5 is fixed on the upper end of the transmission bolt 1.4, the upper jaw transmission part 1.2 and the lower jaw transmission part 1.3 are located between the quick-plug joint 1.1 and the anti-off nut 1.5, and the upper jaw transmission part 1.2 and the lower jaw transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com