Inspection robot instrument recognition method based on specular reflection removal

An inspection robot and mirror reflection technology, applied in the field of instrument identification, can solve the problems of quality preprocessing and instrument reading interference, affecting identification accuracy, and inaccurate readings, so as to improve quality and identification accuracy, reduce safety hazards, Eliminates the effect of specular reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

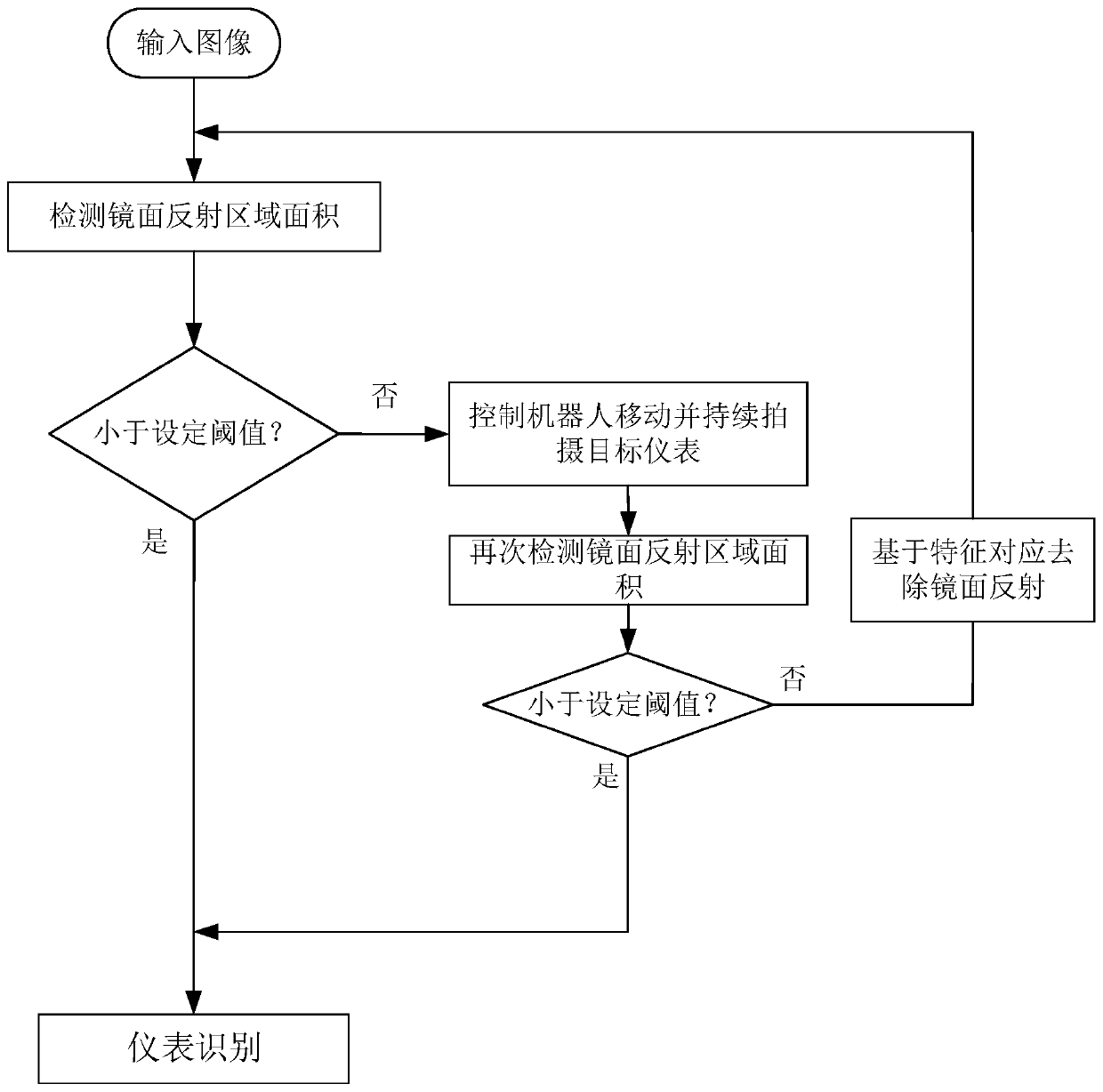

[0044] Such as figure 1 As shown, a method of instrument recognition for inspection robots based on specular reflection removal, the method includes the following steps:

[0045] (1) The inspection robot acquires the image of the instrument to be identified;

[0046] (2) Detect the area of the specular reflection area in the meter image to be identified, if the area of the specular reflection area is less than the threshold, then identify the reading in the image, otherwise perform step (3);

[0047] (3) Control the movement of the inspection robot and continuously capture the image of the target instrument;

[0048] (4) Carry out the area detection of the specular reflection area again on the target instrument image after the inspection robot stops moving, if the area of the specular reflection area is less than the threshold, then identify the reading in the image, otherwise perform step (5);

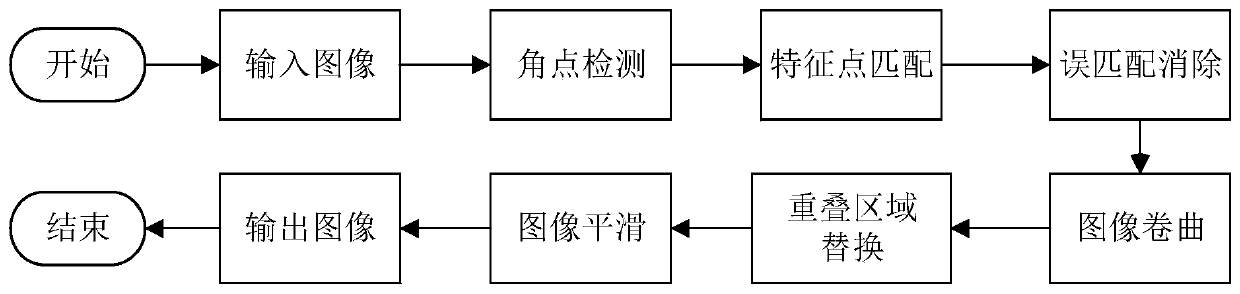

[0049] (5) Process the image of the target instrument during the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com