Strengthened screw type nail for building hinging

A technology for anchors and screws, applied in the direction of screws, pins, threaded fasteners, etc., which can solve the problems of large space of anchors, and the space cannot be completely filled and compressed by particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

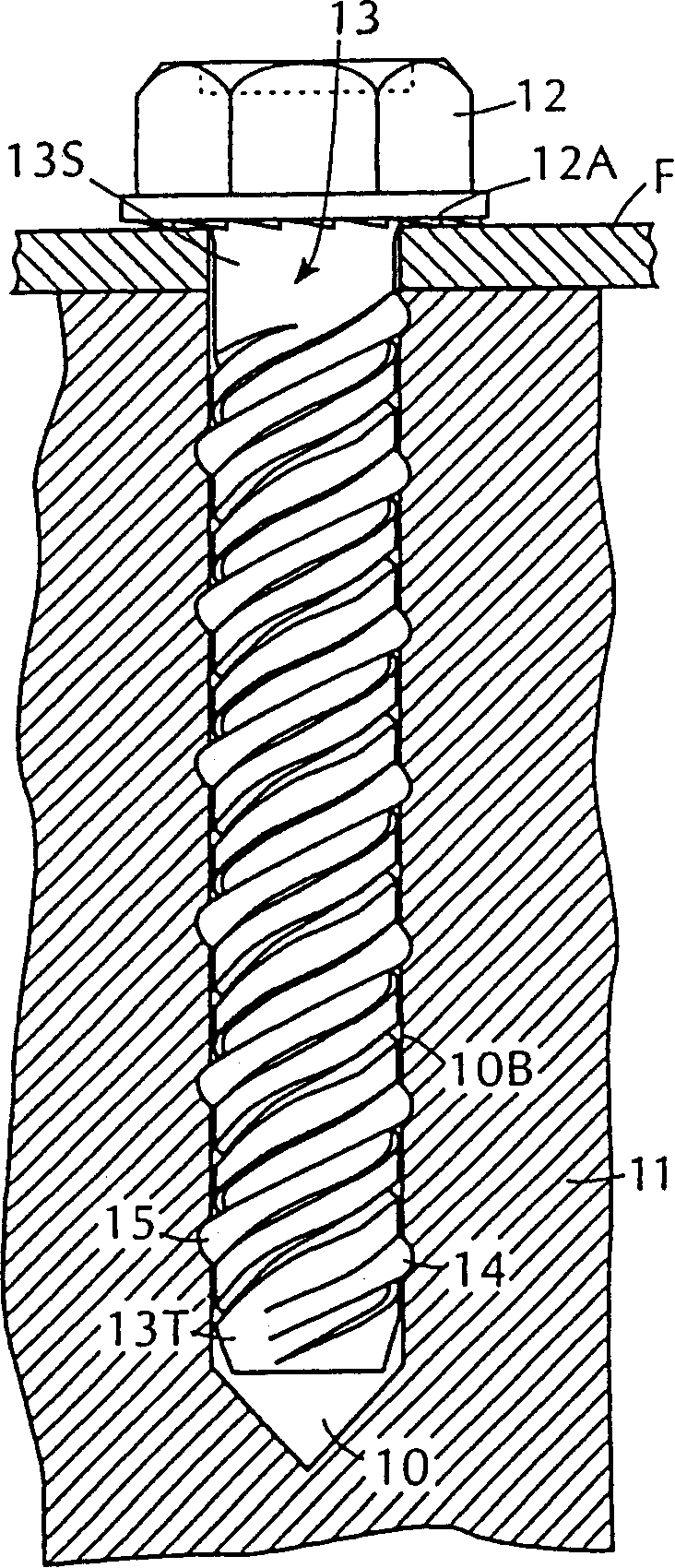

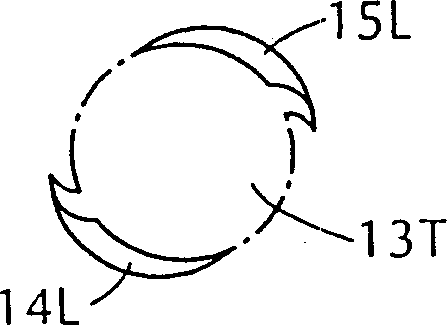

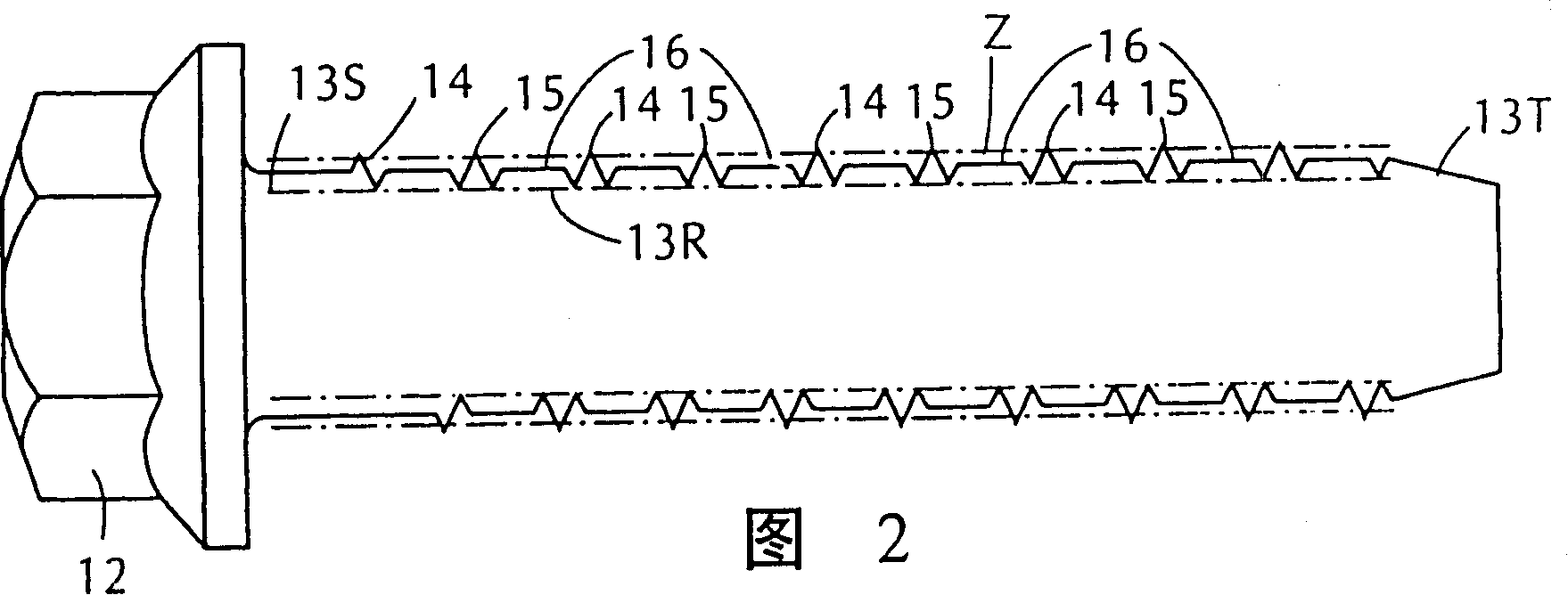

[0032] see now figure 1 , 1A and 2, shown in these drawings is a screw self-tapping masonry anchor according to the present invention, which is installed in a hole 10 drilled in a masonry body 11 to attach a fitting F or other accessories are fastened on it. The anchor is inserted into the masonry hole through a mounting hole on the fitting aligned with the masonry hole. The masonry consists of concrete or other stone masonry materials.

[0033] An anchor made of heat-treated hardened steel or other high-strength, corrosion-resistant metal has a large hexagonal head 12 to enable it to cooperate with a wrench or other torque-generating tool to drive the anchor into the hole middle. When the anchor is tightened, the underside 12A of the head 12 is serrated to frictionally fit the surface of the fitting.

[0034] The masonry anchors disclosed herein are screws with a large head. However, in practice the anchor may be of the screw type, wherein the upper end of the anchor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com