High-precision stand column pile positioning and perpendicularity-regulating device

A column pile, high-precision technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of large positioning deviation, low verticality precision control, etc., achieve long solution time, reduce the difficulty of vertical adjustment, and control accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation manner described in this embodiment. The purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the disclosure of the present application, wherein the words indicating orientation such as front, rear, up, and down are only for the positions of the structures shown in the corresponding drawings.

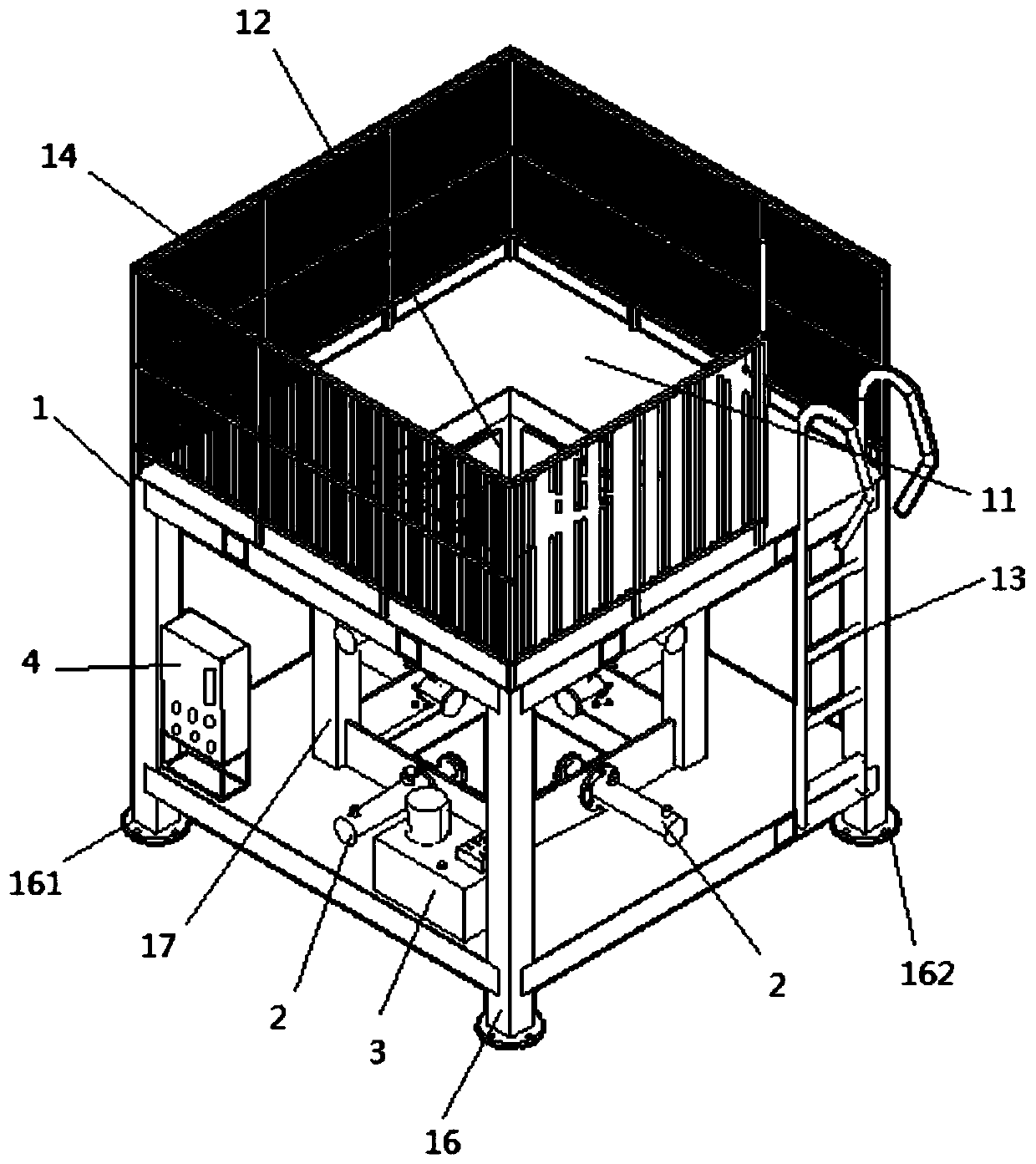

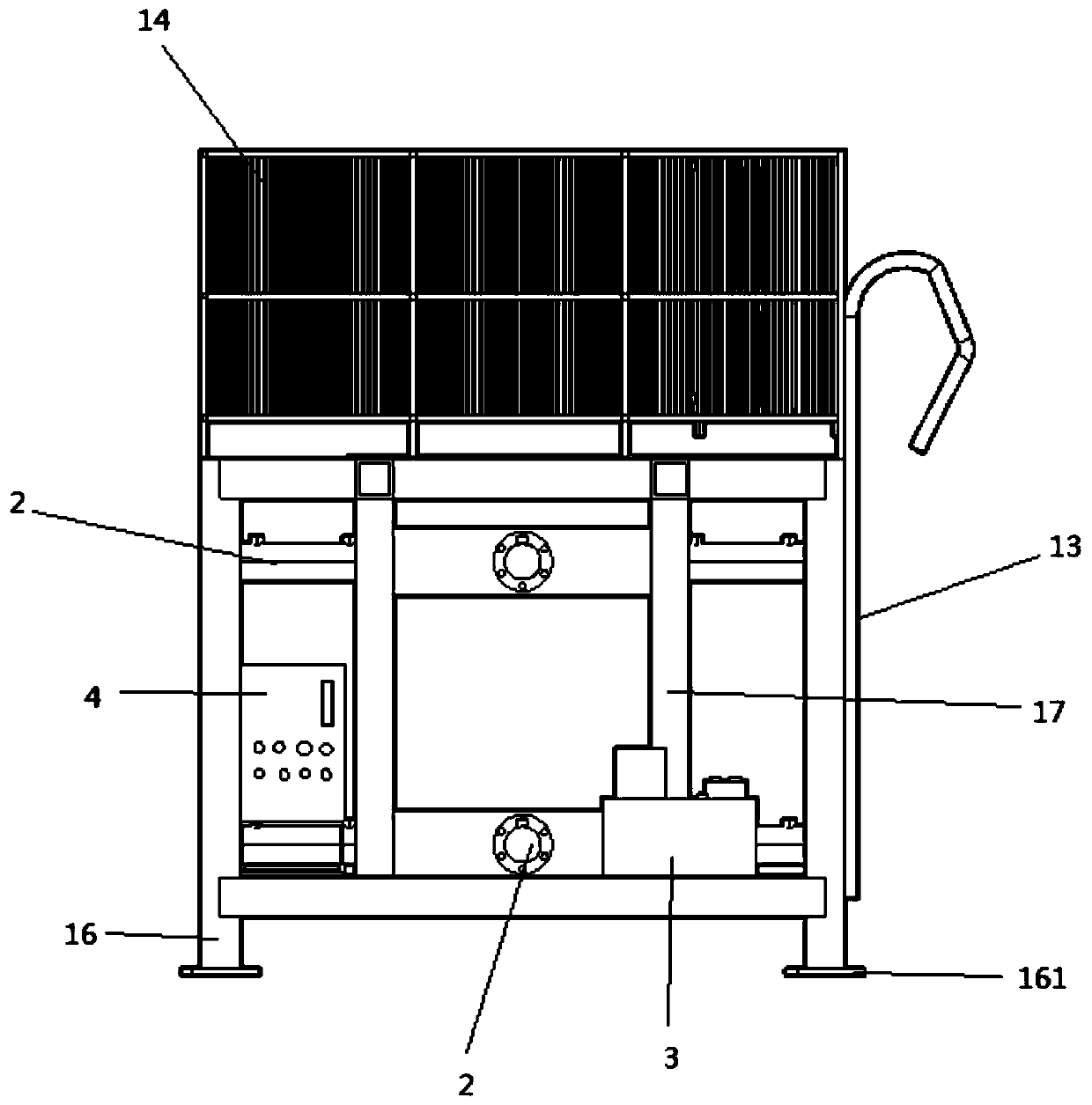

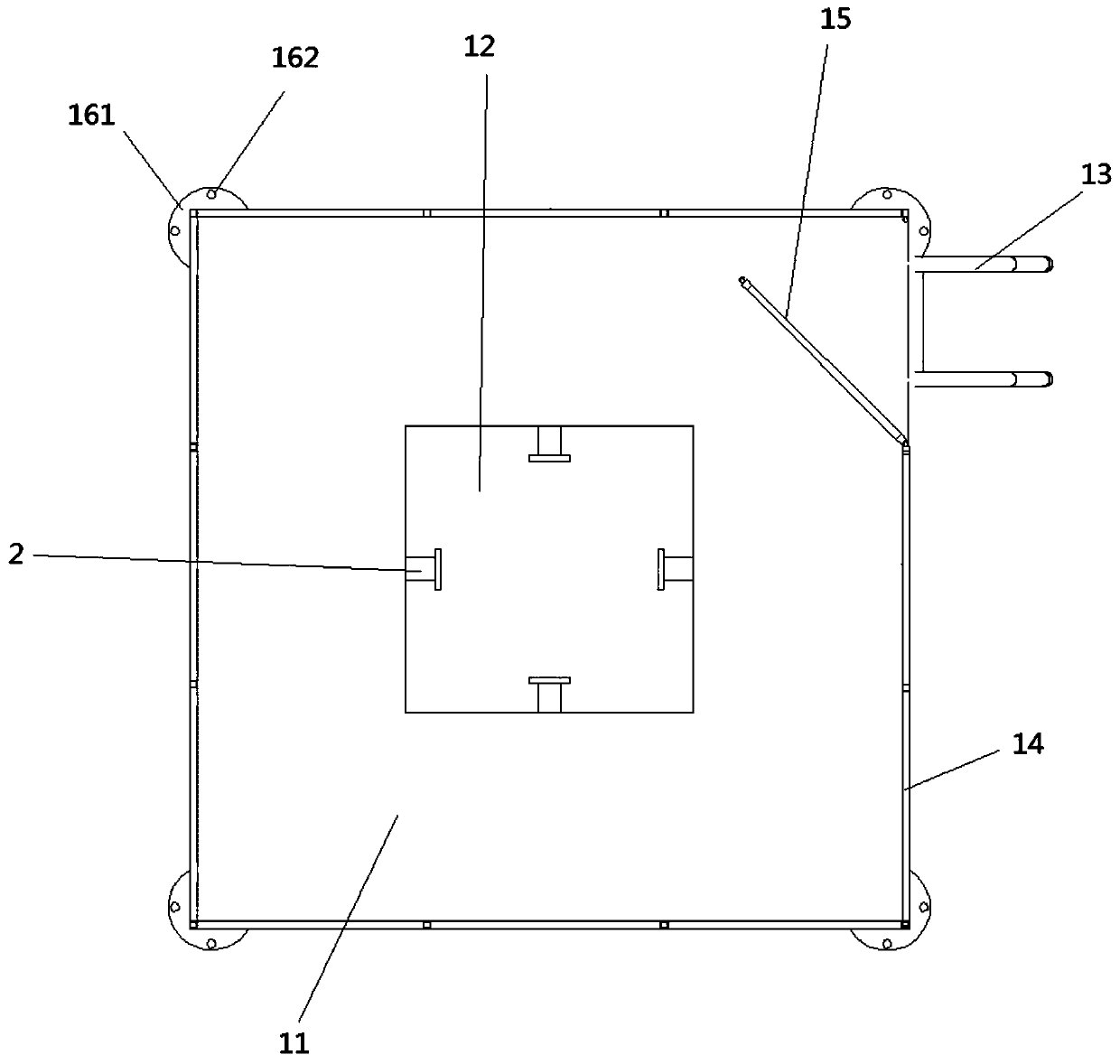

[0015] see Figure 1-3 As shown, the present invention relates to a high-precision column pile positioning and vertical adjustment device, including a correction frame 1, a jacking device 2, a hydraulic oil pump 3 and a control box 4, and the upper end of the correction frame 1 is provided with a working platform 11, so that The center of the correction frame 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com