Water-repellent oil-absorbing three-dimensional porous cotton fabric preparation method

A three-dimensional porous, water-repellent and oil-absorbing finishing technology, which is applied in the field of preparation of three-dimensional porous cotton fabrics, can solve the problems of limited oil-absorbing surface area, difficult to reuse, poor mechanical properties, etc., and achieve good oil spill adsorption and release capacity and large adsorption specific surface area , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

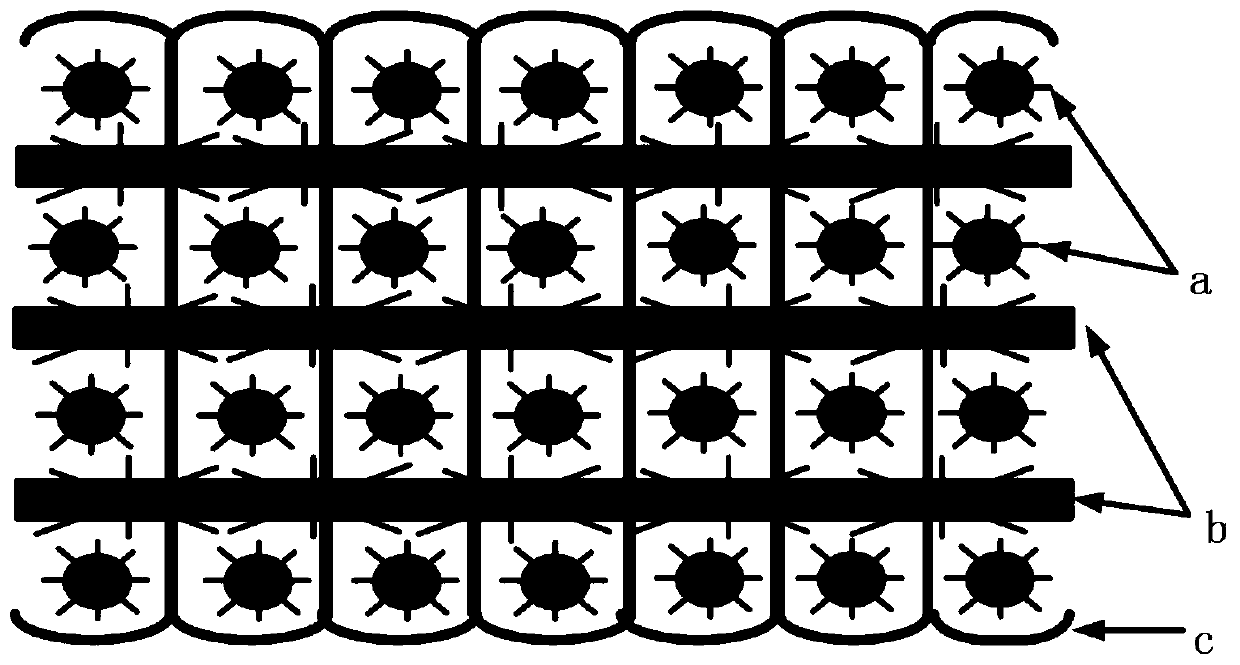

[0024] The preparation method of the water-repellent and oil-absorbing three-dimensional porous cotton fabric of the present embodiment, the method is:

[0025] S1, use three-dimensional loom to interweave warp yarn and weft yarn by binding yarn, obtain three-dimensional porous cotton fabric pre-finished product; Warp yarn in the three-dimensional porous cotton fabric pre-finished product is a hairiness yarn with a density of 15 / 10cm and a fineness of 2800 denier , the weft yarn in the pre-finished three-dimensional porous cotton fabric is a hairiness yarn with a density of 15 / 10cm and a fineness of 2800 denier; Be the hairiness yarn of 200 deniers;

[0026] S2. Mix and stir the silane resin and ethyl acetate for 20 minutes, add the water-repellent finishing agent fluorine-containing silicone oil water-repellent finishing agent, mix and stir for 20 minutes, add the curing agent silane resin curing agent, and mix and stir for 10 minutes to obtain the water-repellent and oil-abs...

Embodiment 2

[0030] The preparation method of the water-repellent and oil-absorbing three-dimensional porous cotton fabric of the present embodiment, the method is:

[0031] S1, the terry fabric and the plain cotton fabric are alternately stacked, and a total of 6 layers are stacked, and then connected by connecting yarn regenerated cellulose fiber bulky yarn to obtain a three-dimensional porous cotton fabric pre-finished product; the weight of the terry cotton fabric 150g / m 2 , the yarn count is 32 strands; the yarn count of the plain weave cotton fabric is 60s × 60s, the warp and weft density (root / 10cm) is 180s × 120s, and the weight is 115g / m 2 The linear density of the connecting yarn regenerated cellulose fiber bulked yarn in the three-dimensional porous cotton fabric pre-finished product is 300 denier; the connecting yarn regenerated cellulose fiber bulked yarn pattern in the described three-dimensional porous cotton fabric pre-finished product is a plain weave structure;

[0032] ...

Embodiment 3

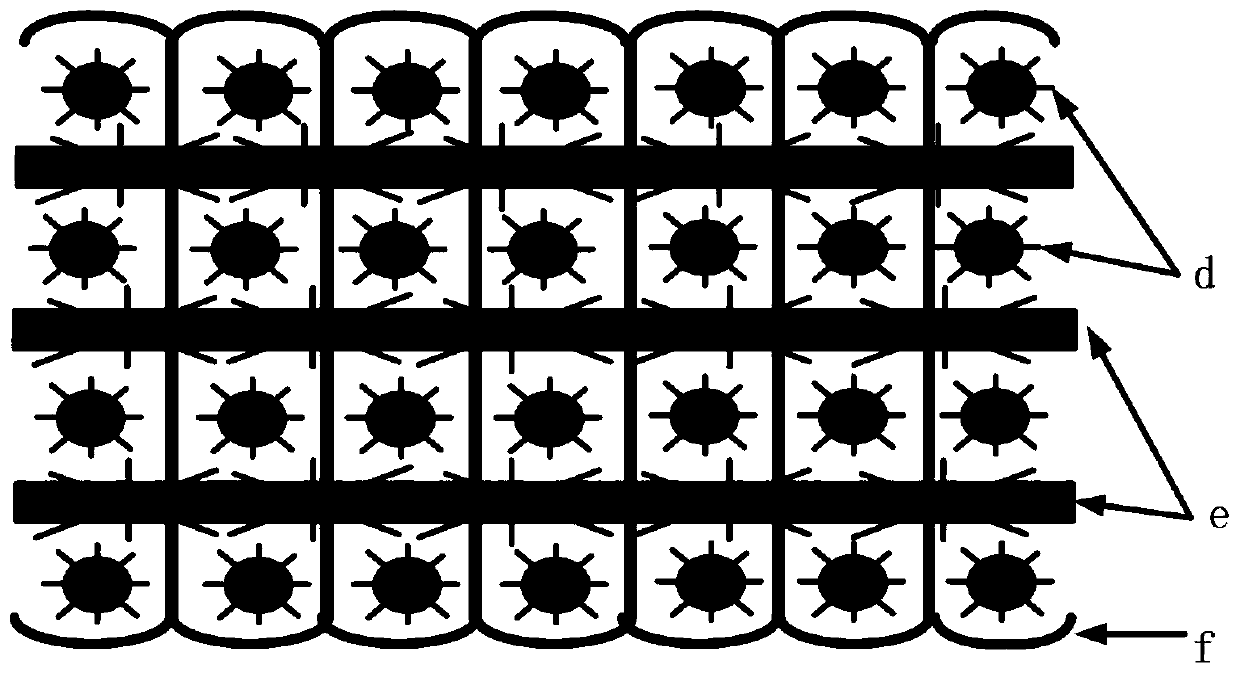

[0036] The preparation method of the water-repellent and oil-absorbing three-dimensional porous cotton fabric of the present embodiment, the method is:

[0037] S1, use three-dimensional loom to interweave warp yarn and weft yarn by binding yarn, obtain three-dimensional porous cotton fabric pre-product; described warp yarn is the hairiness yarn that density is 50 / 10cm, and fineness is 10000 denier, and described weft yarn is density uniform 50 / 10cm, fineness is the terry yarn of 10000 deniers; Binding yarn in the described three-dimensional porous cotton fabric pre-finished product is the hairiness yarn that density is 50 / 10cm, fineness is 1000 deniers;

[0038] S2. Mix and stir the silane resin and ethyl acetate for 20 minutes, add the water-repellent finishing agent fluorine-free water-repellent HA210, mix and stir for 20 minutes, add the curing agent silane resin curing agent, and mix and stir for 10 minutes to obtain the water-repellent and oil-absorbing finishing agent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com