Activated carbon ton bag packaging machine

A packaging machine and activated carbon technology, applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of waste of packaging bag space resources, endangering workers' health, affecting the environment of packaging workshops, etc., to improve packaging efficiency and save packaging. Cost and transportation cost, the effect of improving the utilization of packaging space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

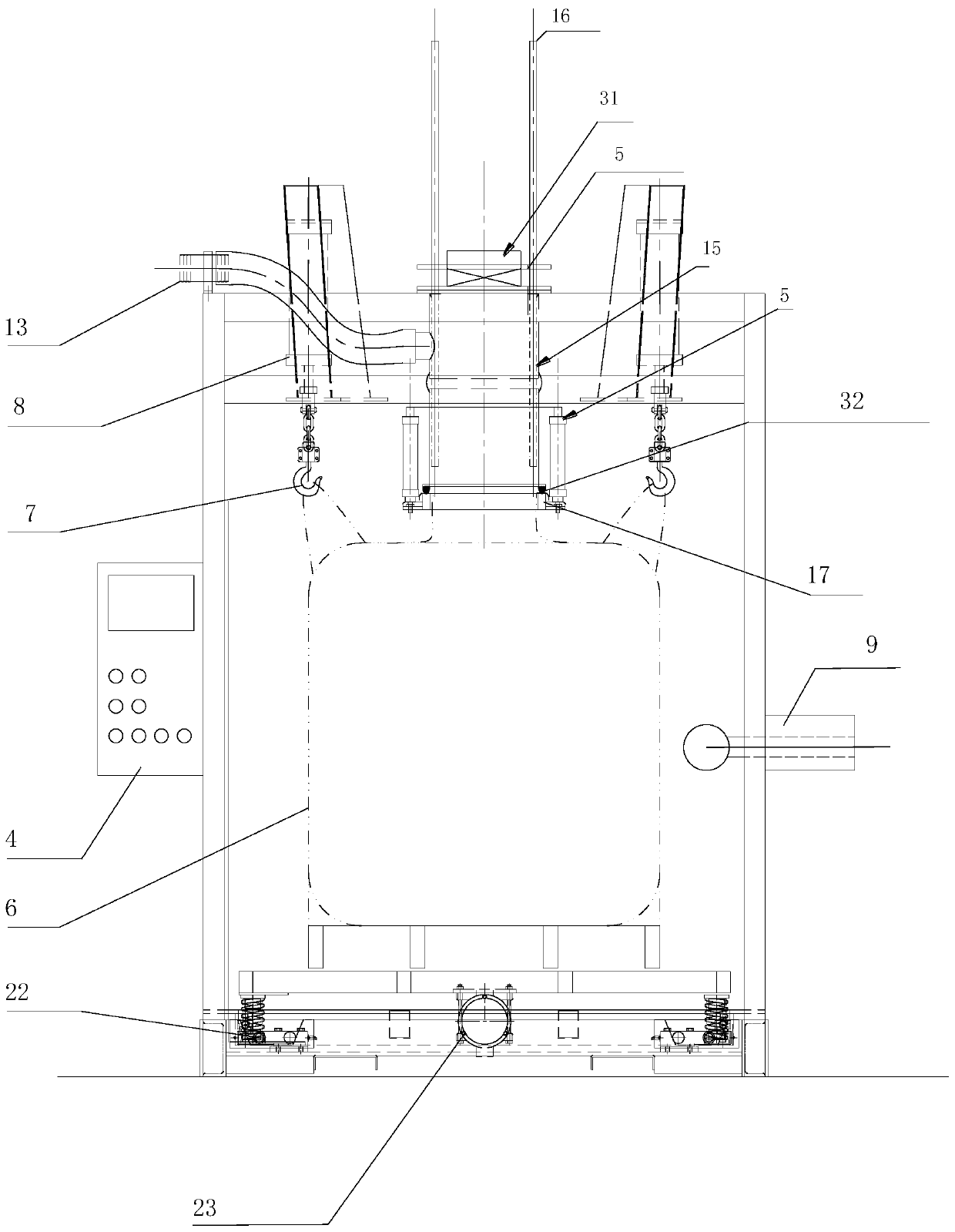

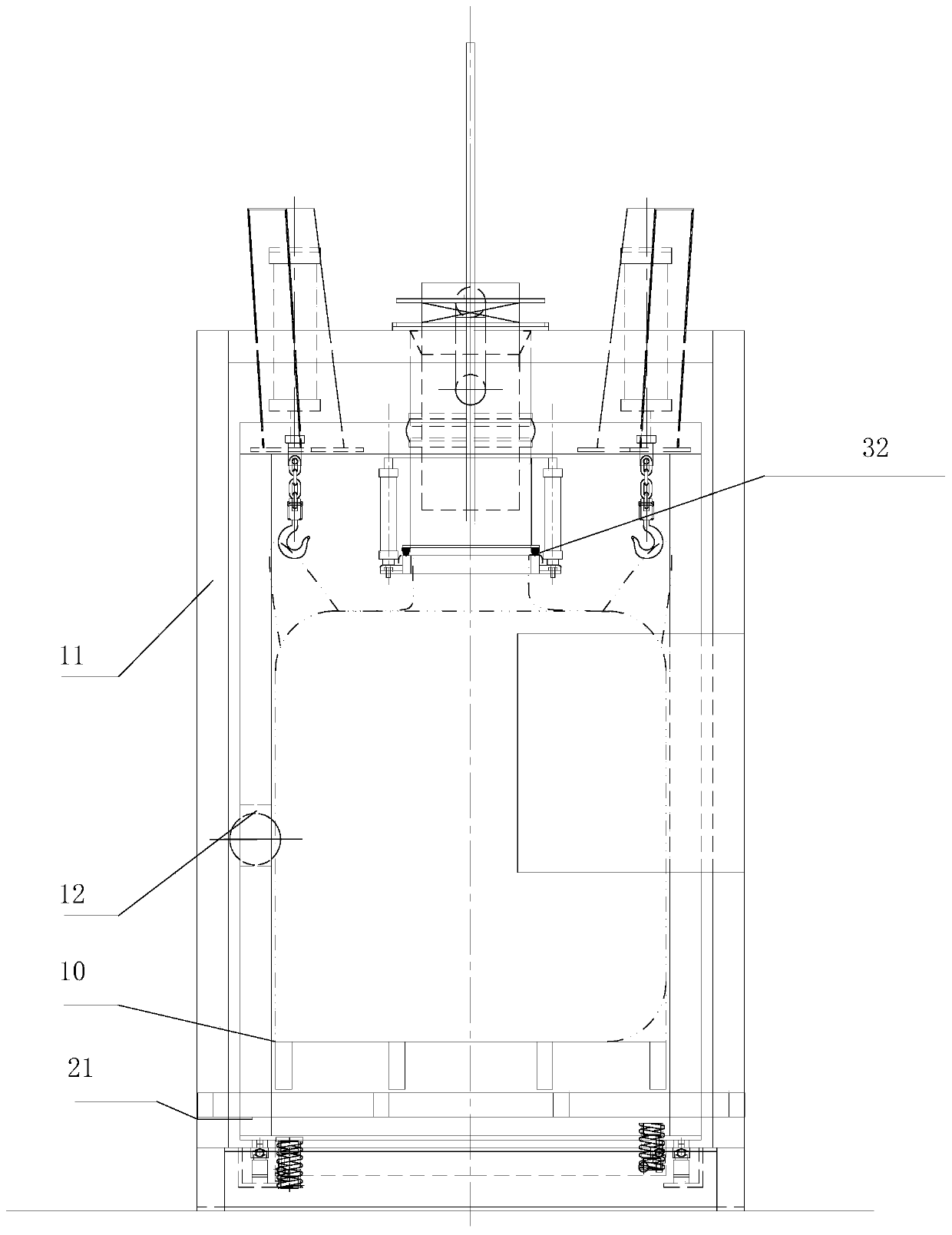

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] refer to figure 1 with figure 2 , an activated carbon ton bag packaging machine, including a frame, a silo, a packaging unit and a control device 4, the packaging unit includes a bucket, a weight sensor for detecting the weight of activated carbon in the bucket, a bag clamping mechanism, a vibration mechanism, Pushing and shaking mechanism and vacuum device, the feed port 31 of the feed bucket is softly connected with the discharge port of the feed bin, and a butterfly valve 5 is provided at the feed port 31 of the feed bucket, and the discharge port of the feed bucket There is a bag clamping mechanism at 32, the big bag 6 is placed on the big bag tray 10, the big bag tray 10 is set on the vibration mechanism, the weight sensor is set on the material barrel, and the pushing and shaking mechanism is used for lifting and pushing Big bag 6, the vacuum device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com