Ultraviolet-resistant children's clothing fabric and manufacturing method thereof

An anti-ultraviolet, production method technology, applied in the field of children's clothing fabrics, can solve problems such as influence, and achieve the effects of good touch feeling, high initial adhesion, and reduced influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Such as figure 2 As shown, the side of the base cloth layer 9 away from the reflective layer 4 is provided with a shielding cloth strip 10, and the shielding cloth strip 10 is located at the periphery of the base cloth layer 9, and the base cloth layer 9 is provided with A number of round holes 11 can be used to sew patterns on the base cloth layer 9, and the covering cloth strips 10 can block the sewing lines. The round holes 11 can be placed with decorative objects such as buttons, which are convenient for fixing the decorative objects for sewing operations, patterns and decorations. Things add to the appearance of the fabric, making it more popular with children.

Embodiment 2

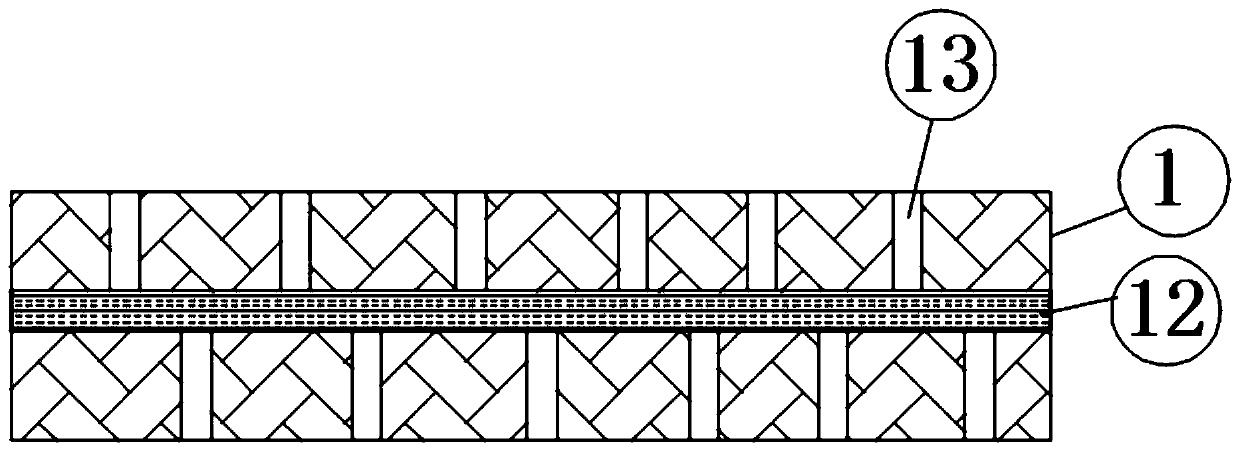

[0051] Such as image 3 As shown, when the fabric is used for summer clothing, the middle part of the cotton layer 1 is provided with an antibacterial layer 12, and the antibacterial layer 12 is formed by blending mulberry silk fiber and cupro ammonia fiber, and the cotton layer 1 is provided with a number of through holes 13, the through holes 13 are respectively located on both sides of the antibacterial layer 12, the through holes 13 can increase the air permeability of the cotton layer 1, reduce the stuffy feeling of the fabric, the cotton layer 1 It is woven from combed cotton yarn, which has high washability and durability. Mulberry silk fiber is conducive to improving moisture absorption and ventilation, and has a good antibacterial effect. Cupro ammonia fiber has good water absorption and will not produce Sultry feeling, soft and not easy to generate static electricity, the combination of the two can not only achieve the effect of antibacterial, but also ensure good pe...

Embodiment 3

[0053] Such as Figure 4 As shown, when the fabric is used for winter clothing, a windproof layer 14 is added on both sides of the cotton layer 1, and the windproof layer 14 is made of polyurethane film, which has high adhesion and low temperature resistance. It can increase the cold resistance of the fabric. The cotton layer 1 is made of combed cotton and cotton fiber blended. The wicking effect of the cotton fiber makes it soft and warm, moisture-conducting and dry, hygienic and antibacterial. Cotton fiber can not only ensure the antibacterial effect of the cotton layer 1, but also increase the thermal effect of the cotton layer 1, and the clothes made are suitable for wearing in winter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com