Dough splitting device

A technology for dividing dough and dough, which is applied in the fields of dough cutting machinery, baking, food science, etc., can solve the problems of high maintenance cost, difference in dough quantity, high cost, etc., and achieves low structural precision requirements, low cost, and suitable for wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

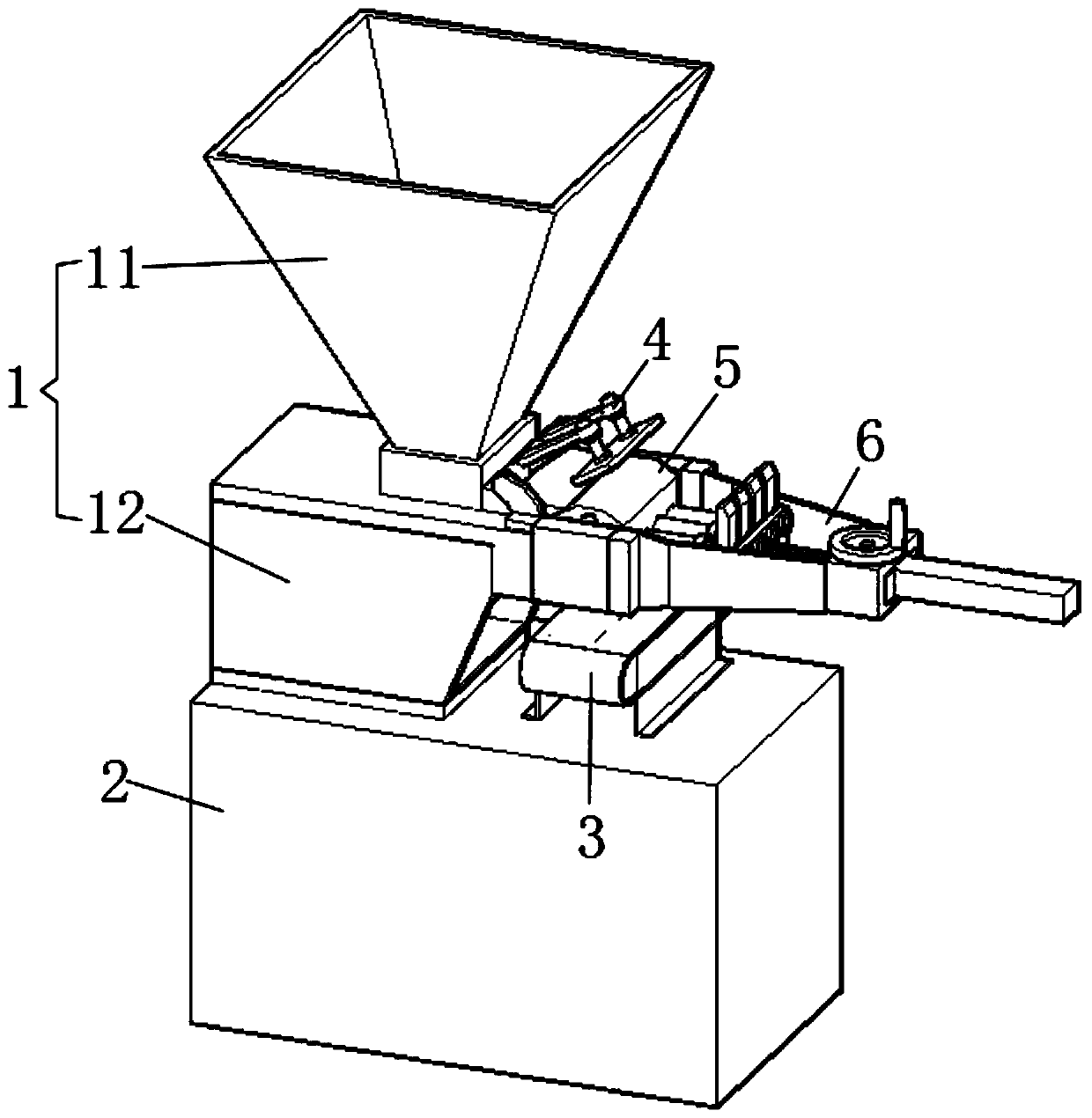

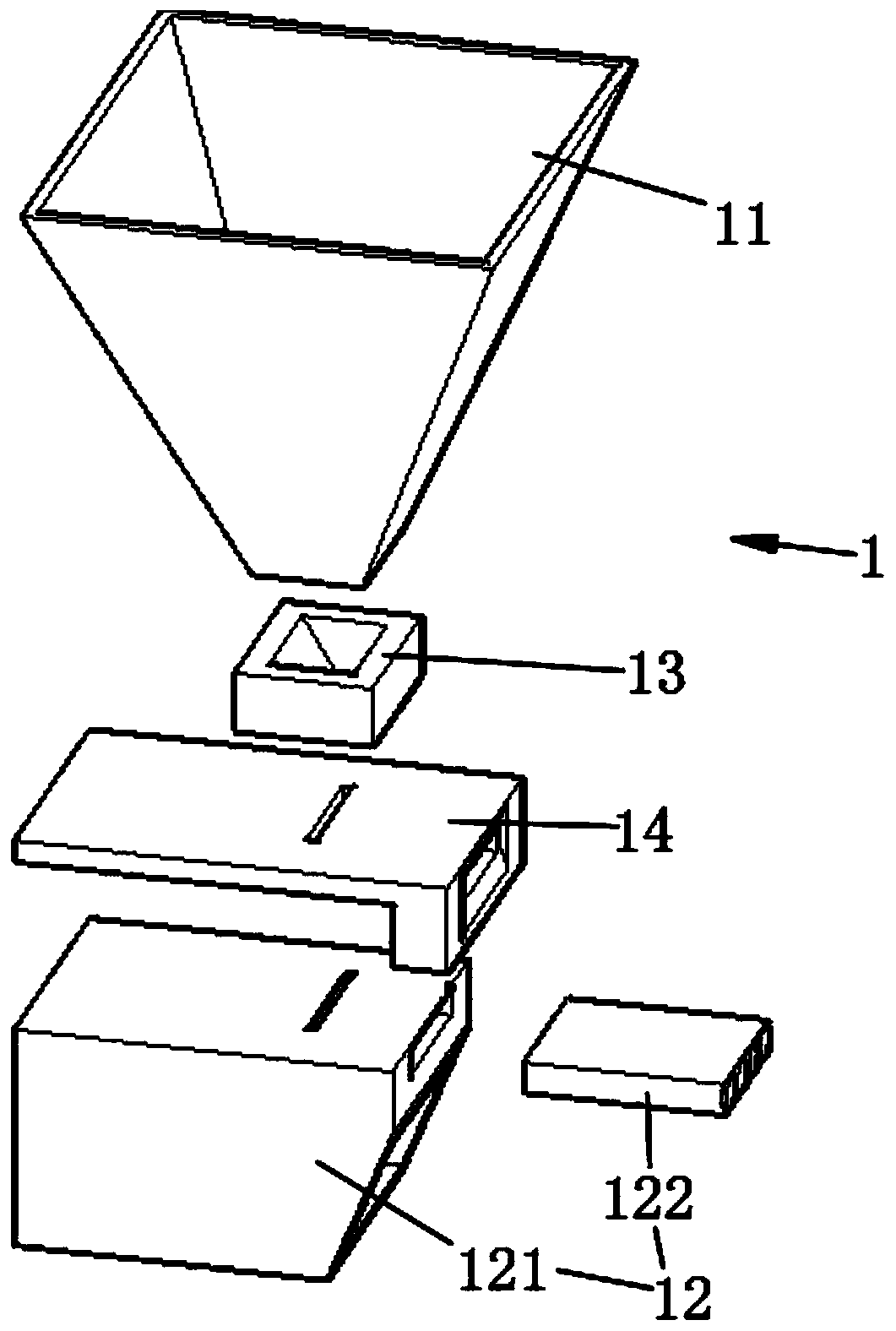

[0042] refer to figure 1 , this embodiment discloses a dough grouping device, including a feeding device 1 , a base 2 , a conveying device 3 and a grouping mechanism 5 . The feeding device 1 is installed on a base 2 . The grouping mechanism 5 is rotatably connected to the feeding device 1 . The conveying device 3 is arranged below the group separating mechanism 5 .

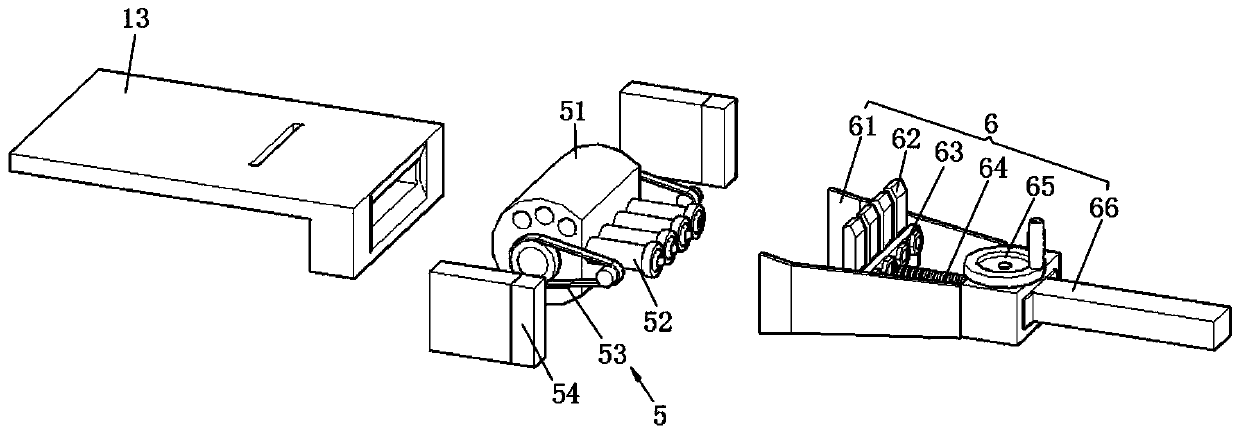

[0043] The grouping mechanism 5 includes a grouping cylinder 51 rotating along its axis, a movable column 52 and a cylindrical through hole 55 . Cylindrical through-holes 55 run side by side on the curved surface of the grouping cylinder 51 . A movable post 52 is inserted into a port of the cylindrical through hole 55 . When the cylindrical through hole 55 is aligned with the feeding port of the feeding device 1 , the dough is fed into the cylindrical through hole 55 from the feeding device 1 , and the movable column 52 is squeezed outward from the cylindrical through hole 55 . When the cylindrical through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com