Robust prediction control method for multi-stage batch asynchronous switching process aiming at various interferences

A technology of predictive control and switching process, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of iterative learning control effect reduction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

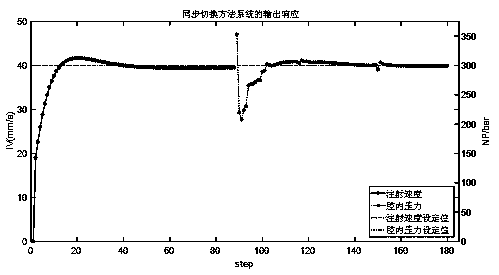

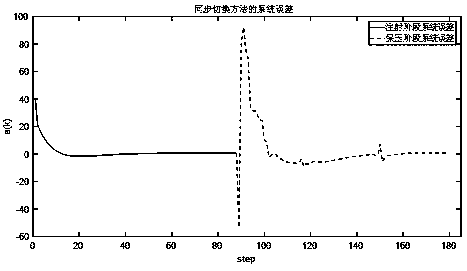

[0104] Embodiment: The present invention simulates the injection stage and pressure holding stage in the injection molding process. The simulation adopts the synchronous switching method and the asynchronous switching method proposed by the present invention respectively. Both methods output responses and control input images such as Figure 1-6 shown.

[0105] Depend on figure 1 with figure 2 It can be seen that when the pressure in the cavity reaches the switching condition of 350 bar, the system state has switched from the injection phase to the pressure holding phase, but the controller has not completed the switching, and there is a time difference of 21s between the switching of the system state and the switching of the controller. At this point the system is in asynchronous switching state.

[0106] Depend on figure 1 with Figure 4 It can be seen that the asynchronous switching state cannot be avoided by using the synchronous switching method, so that the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com