Stirrer mechanical seal pumping circulation device

A technology of mechanical seals and circulation devices, which is applied to mixer accessories, engine seals, mechanical equipment, etc., can solve the problems of large fluctuations, poor sealing liquid circulation, and reduced service life of mechanical seals, so as to achieve uniform flow and pressure, Good self-circulation ability and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

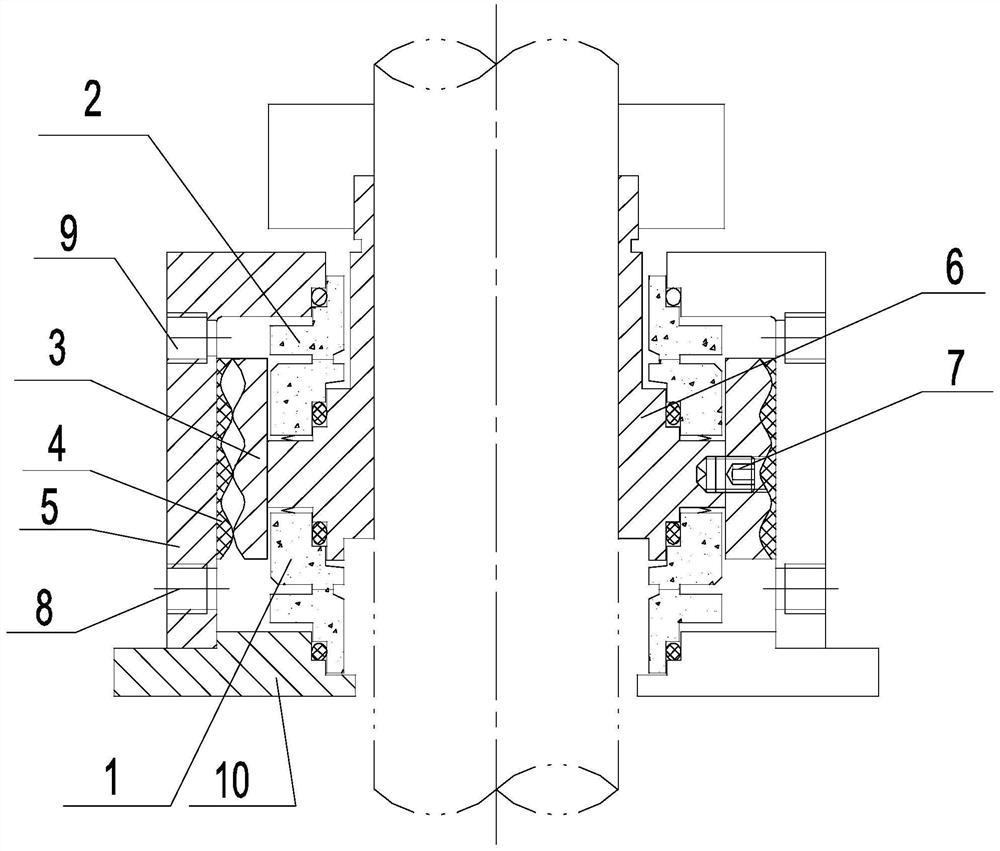

[0020] like figure 1 , a mechanical seal pumping circulation device for an agitator, the top of the sealing chamber 5 is connected to the shaft sleeve 6 through the atmosphere side sealing core 2, the bottom of the sealing chamber 5 is fixedly connected to the base 10, and the base 10 and the shaft sleeve 6 are sealed through the medium side The cores 1 are connected to form a liquid-sealed cavity, the stator 4 is fixed on the sealed cavity 5 , the rotor 3 is fixed on the shaft sleeve 6 , and the rotor 3 is at the relative position of the stator 4 .

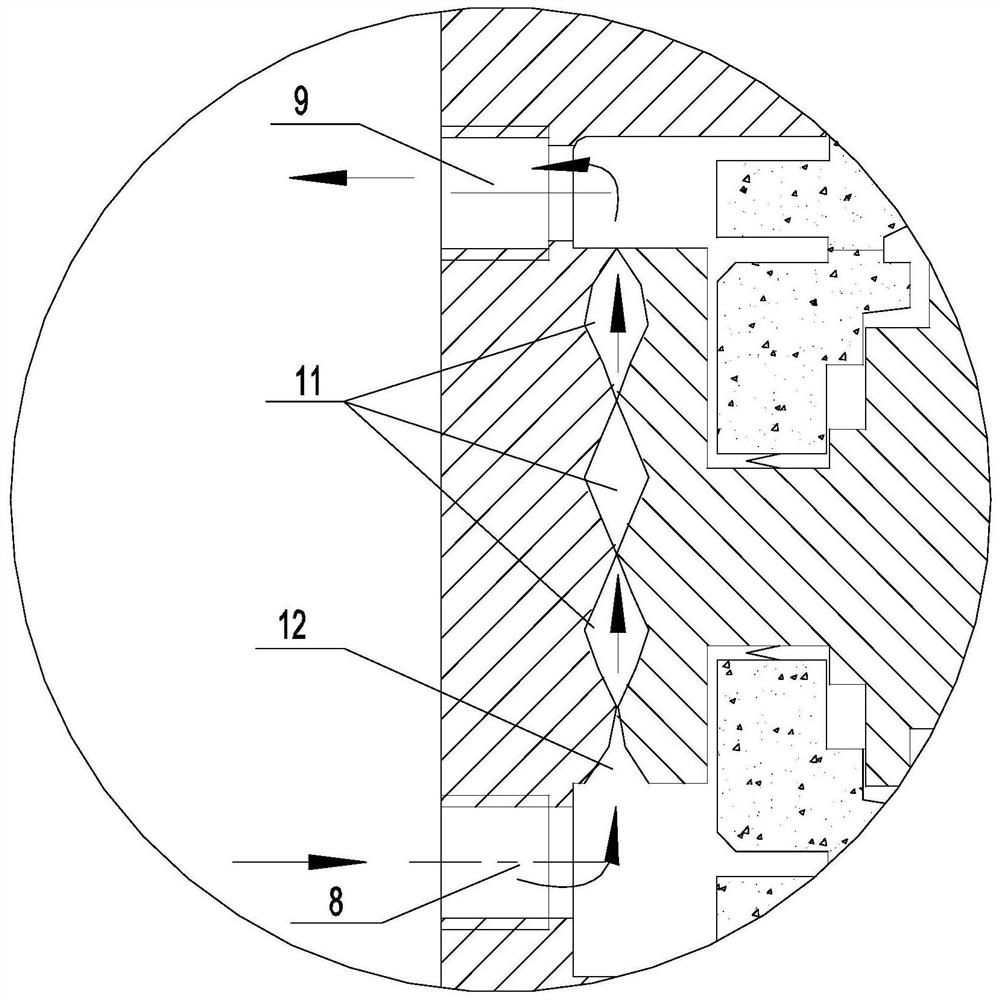

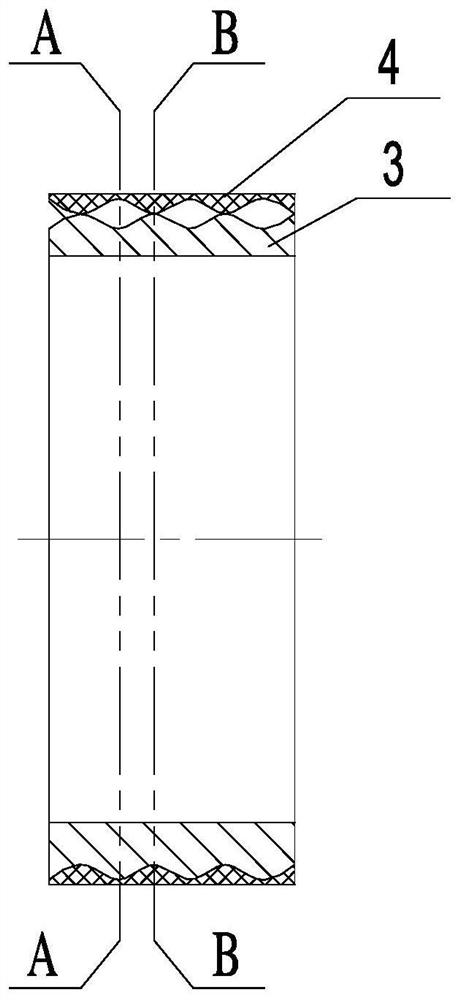

[0021] like image 3 and Figure 4 , the rotor 3 and the stator 4 are spiral ring structures, the space between the rotor 3 and the stator 4 forms a cavity 11 , and the end space of the rotor 3 and the stator 4 forms a V end 12 of the cavity. With the rotation of the rotor 3, the cavity 11 is formed and then disappears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com