Reducer for copper tube machining

A technology of reducer and copper tube, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of restricting the application of the reducer, performance improvement, influence, and the inapplicability of the lubrication system, and achieves simple structure, The overall structure is simple, the effect of lubrication stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

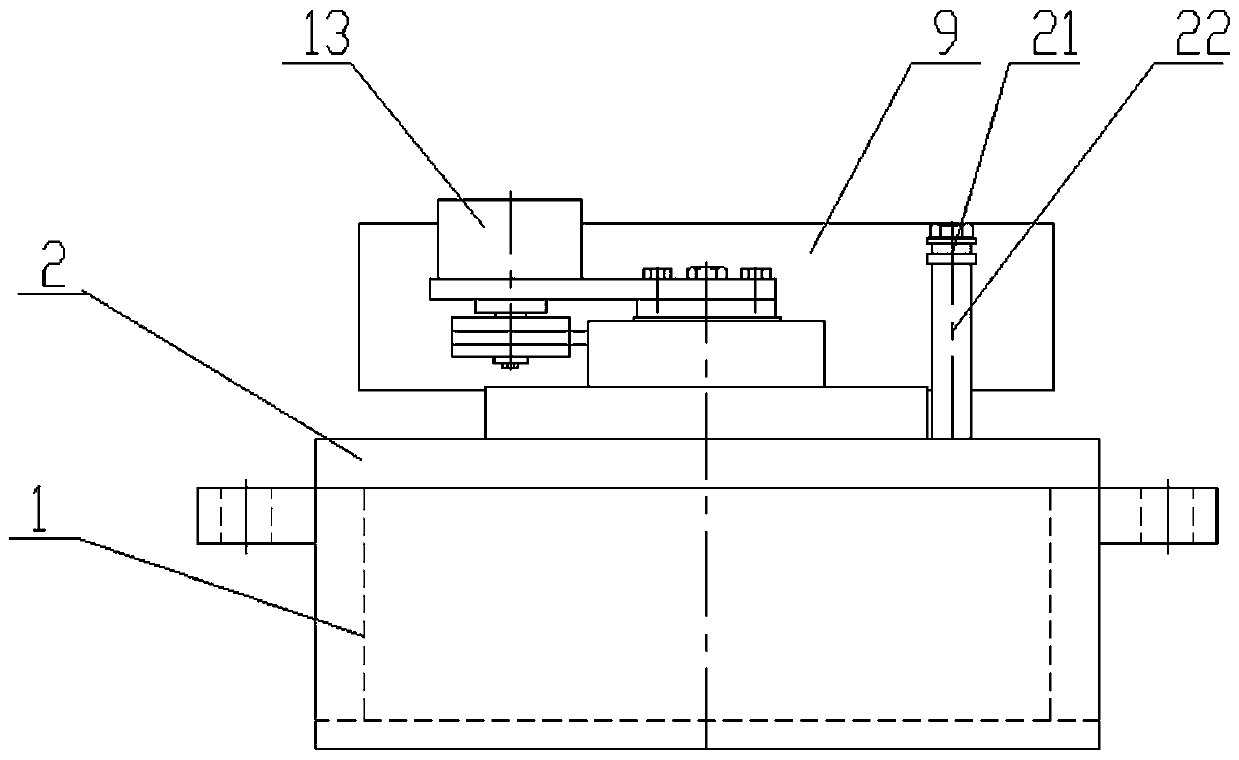

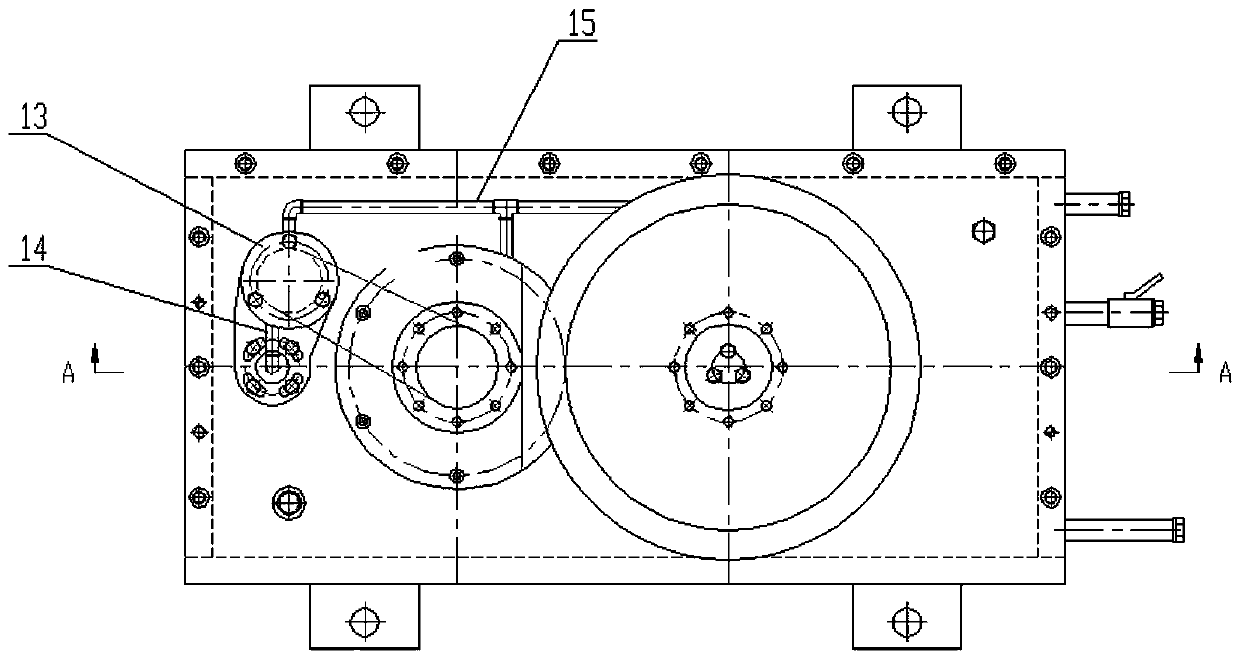

[0015] Further description will be made below in conjunction with the accompanying drawings.

[0016] Figure 1-4 Shown: a reducer for copper pipe processing includes a box body 1, a box cover 2, an input shaft 3, an output shaft 4, a gear set 5, an upper bearing 6, a lower bearing 7, a transparent cover 8, an input pulley 9, a lubricating Drive wheel 10, belt 11, lubricated driven wheel 12, multi-piece two-way lubricating pump 13, oil inlet pipe 14, high pressure oil pipe 15, support seat 16, screw plug 17, oil filling pipe 18, valve 19, discharge pipe 20, breathable cap 21, ventilation pipe 22. The input shaft 3 and the output shaft 4 are parallel to each other, and are arranged in the box body 1 through the upper and lower bearings 6, 7 through the transparent cover 8 to vertically penetrate the box cover 2, and the upper side of the box body is equipped with a refueling tank with a screw plug 17. Pipe 18, a discharge pipe 20 with a valve 19 is provided on the lower side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com