Sealing device for high-gas soft coal seam drilling and sealing method thereof

A technology of soft coal seams and sealing devices, which is applied in the directions of sealing/seal, gas discharge, safety devices, etc., can solve problems such as complicated procedures, poor effects, and failure to reach the sealing state, and achieve simple structure of the sealing device and simple device structure , Easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

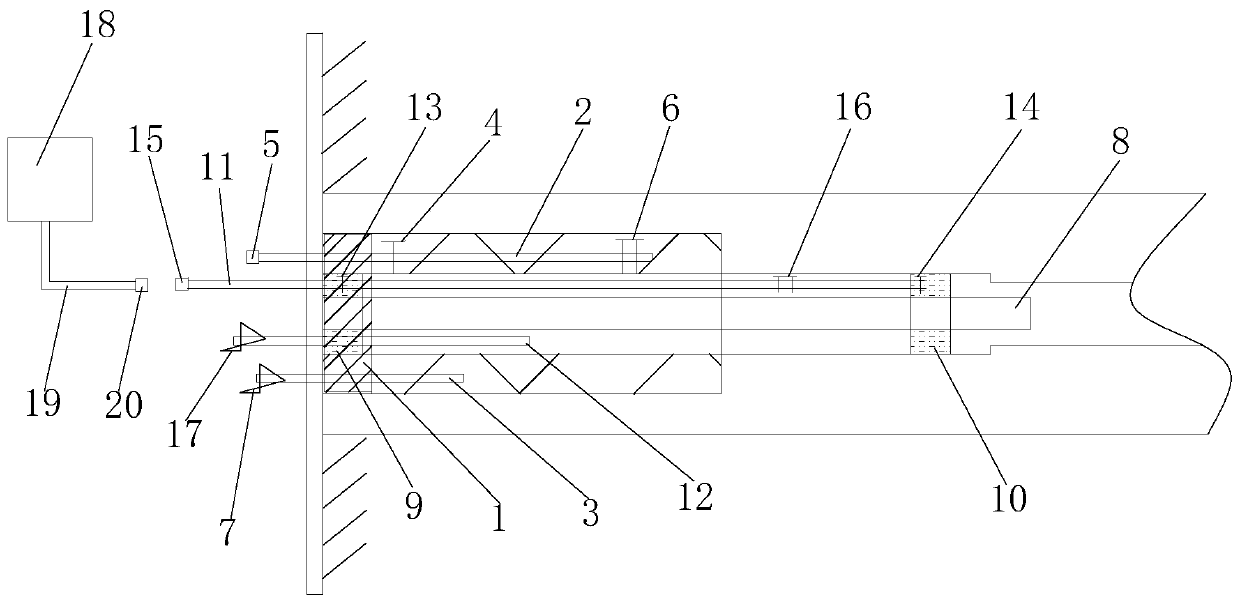

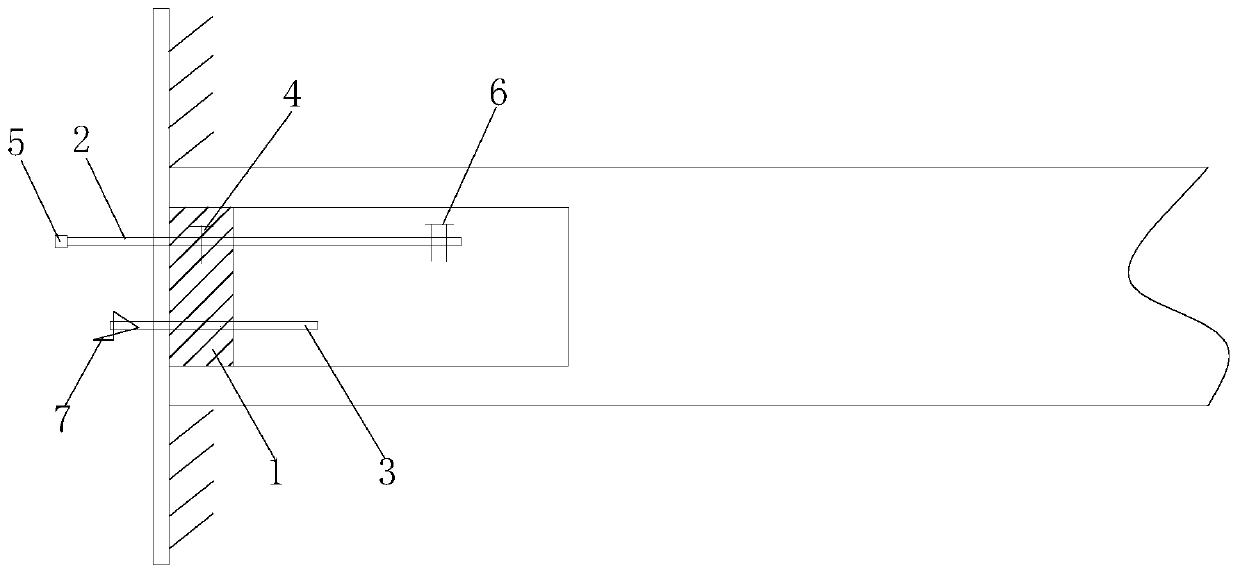

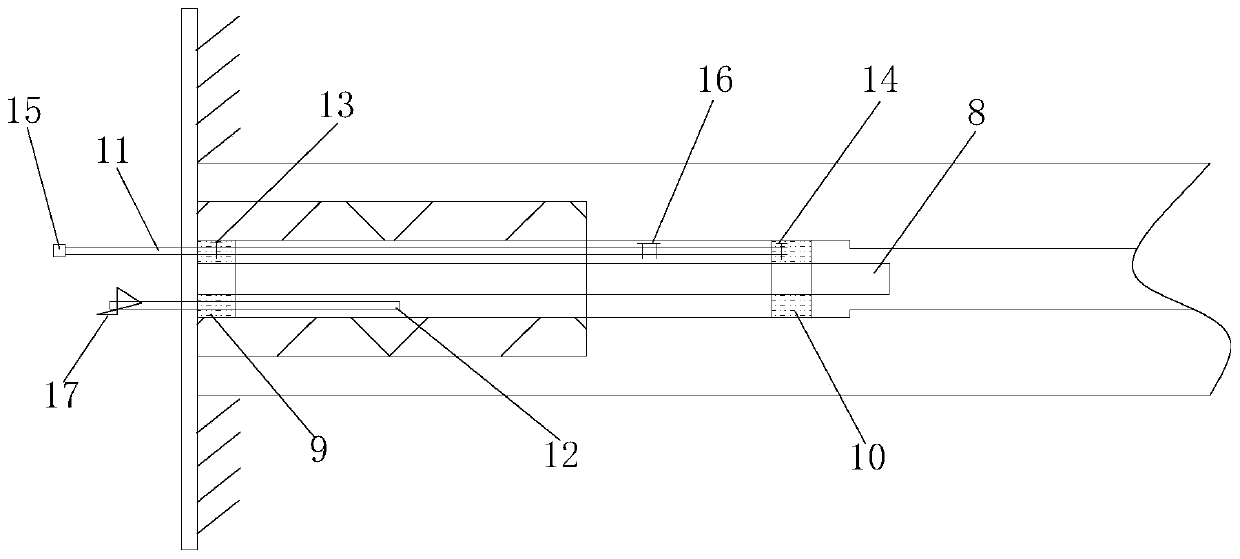

[0041] Such as Figure 1 ~ Figure 3 As shown, the sealing device for high-gas soft coal seam drilling of the present invention includes reinforcement support layers, sealing layers and extraction pipes 8 arranged in concentric circles and arranged from large to small diameters, and the reinforcement support layers Including the first bladder 1, the first grouting pipe 2 and the first grouting pipe 3, the first grouting pipe 2 and the first grouting pipe 3 both pass through the first bladder 1, the first grouting A section of the grout pipe 2 located in the first bag 1 is provided with a first one-way valve 4, and the end of the first grout pipe 2 close to the coal seam drilling hole is provided with a first quick-plug interface 5, the first The other end of a grouting pipe 2 is provided with a first blasting valve 6, and the first grouting pipe 3 is provided with a first shut-off valve 7 outside the coal seam borehole; the sealing layer includes a second bladder 9, The third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com