Heat insulating and pasting structure for independent foundation heat breaking bridge of ultra-low energy consumption building and construction method

An independent foundation and thermal insulation technology, which is applied in the direction of infrastructure engineering, buildings, protection devices, etc., can solve the problem of isolating the heat transfer of independent foundation structures, and achieve the effect of simple construction, expanding the scope of application, and isolating heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

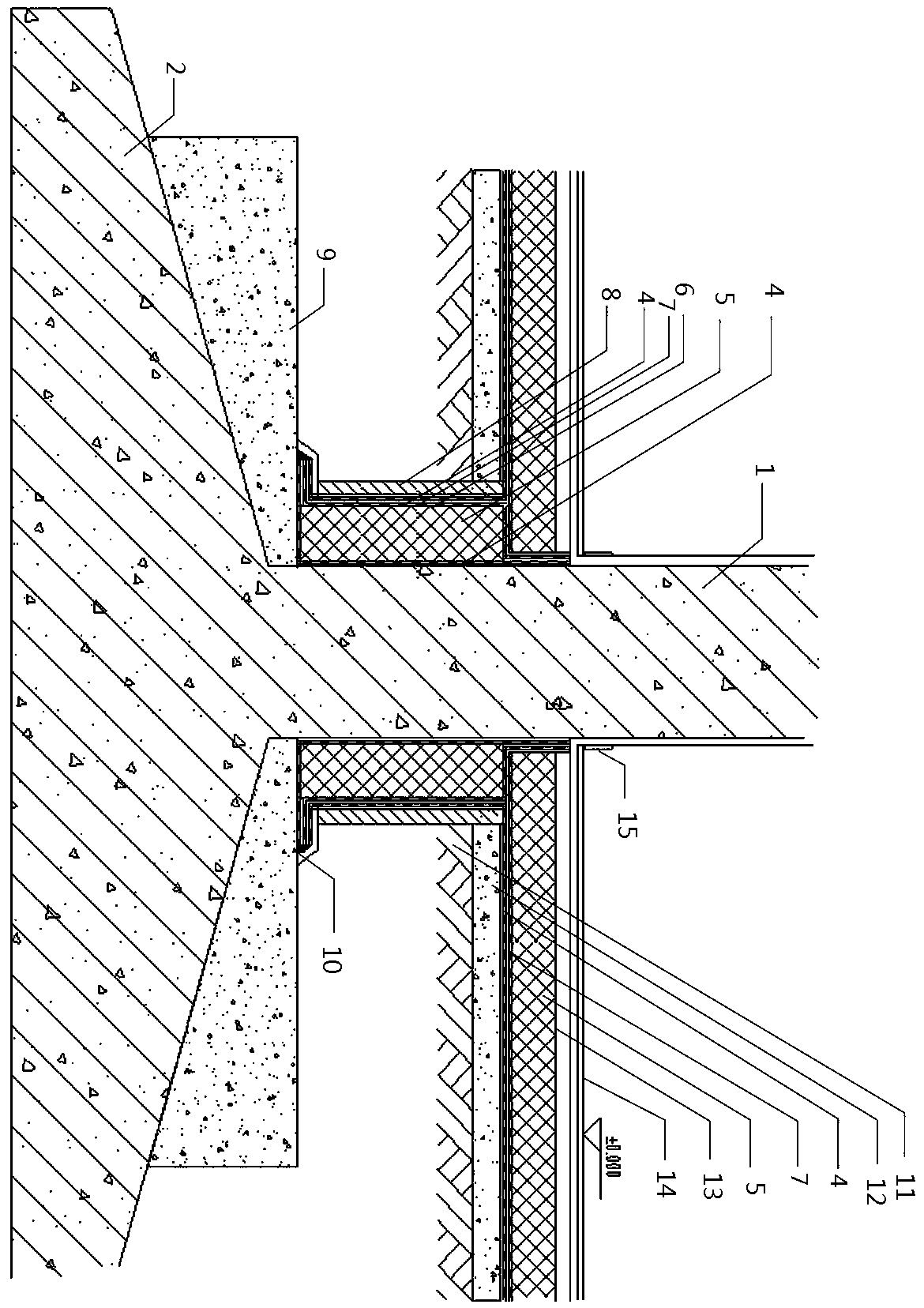

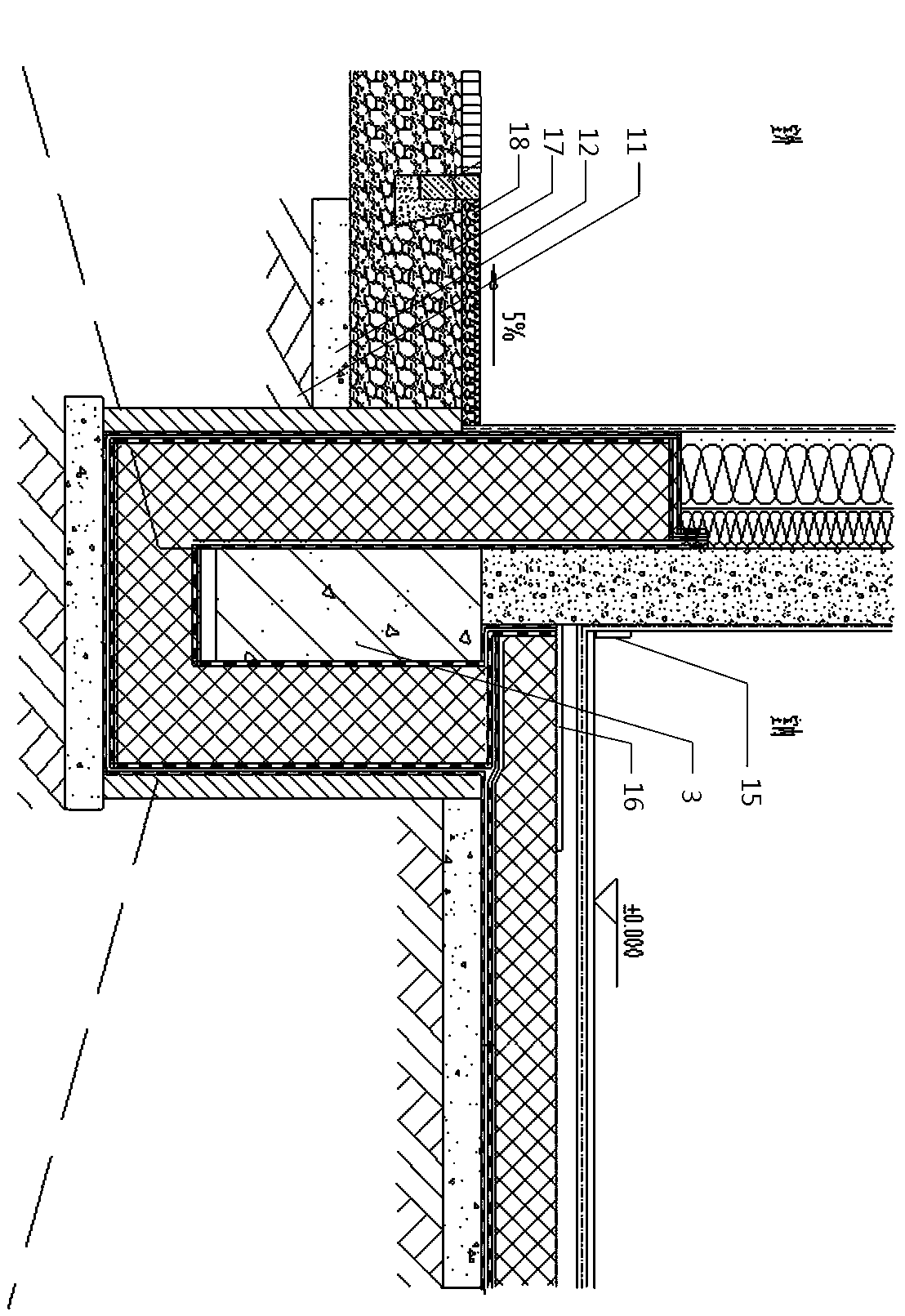

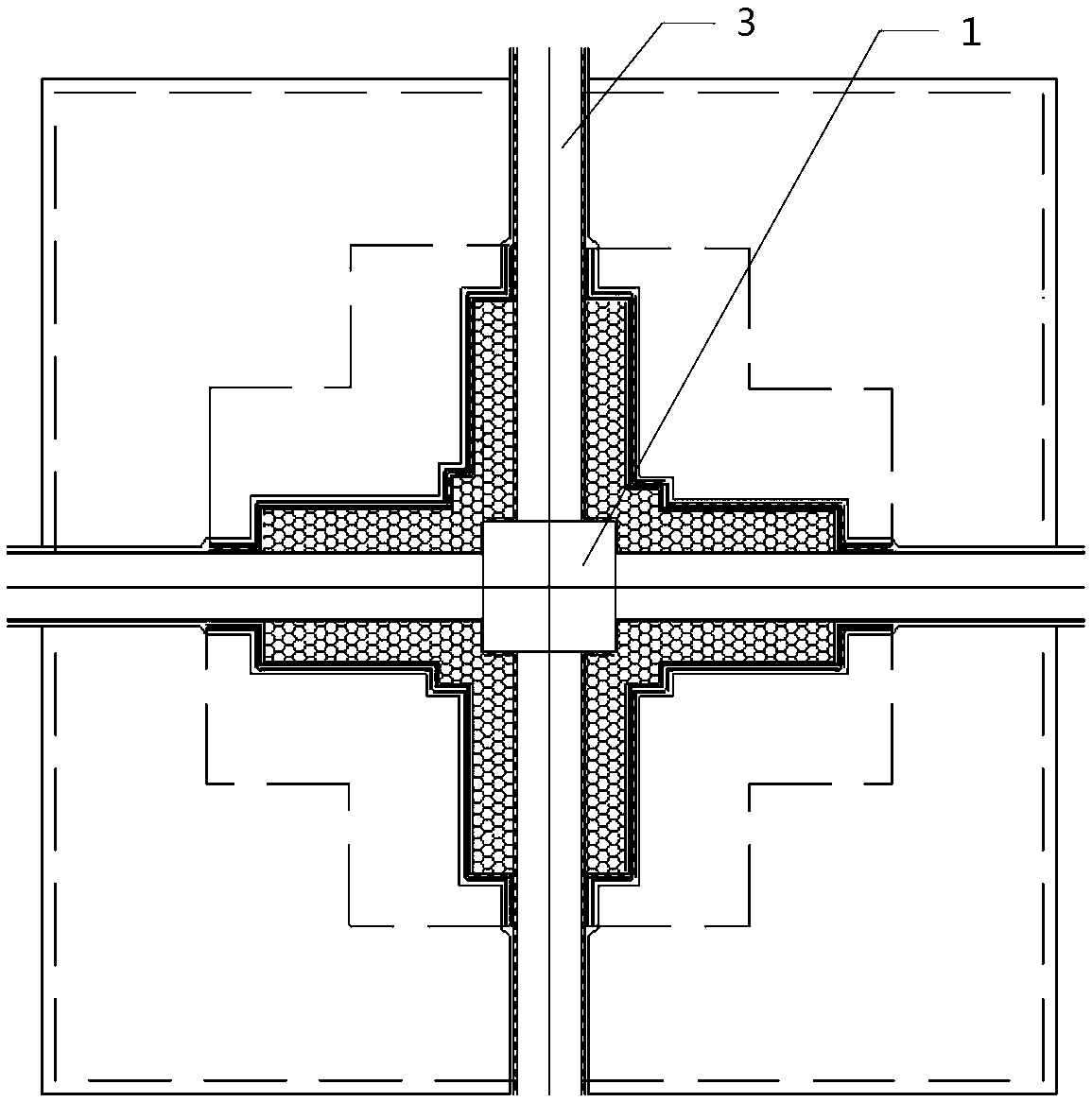

[0033] Ultra-low energy consumption building independent foundation thermal insulation bridge thermal insulation paste structure and construction method, ultra-low energy consumption building independent foundation thermal insulation bridge thermal insulation bonding structure includes independent foundation, and thermal insulation bridge insulation layer pasted on the surface of independent foundation; independent foundation includes matrix layout The structural column 1, the cap 2 arranged under the structural column, and the ground beam 3 arranged between the caps vertically and horizontally; the thermal insulation layer of the thermal break bridge consists of 4mm thick fire-baked polyester laid sequentially from the outside to the inside. Tire SBS waterproof membrane layer 4, 200mm thick XPS board insulation layer 5, 20mm thick cement mortar protective layer 6, self-adhesive polyester tire SBS waterproof membrane layer 7, 4mm fire-baked polyester tire SBS waterproof membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Extension length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com