Oocystis algae culture process

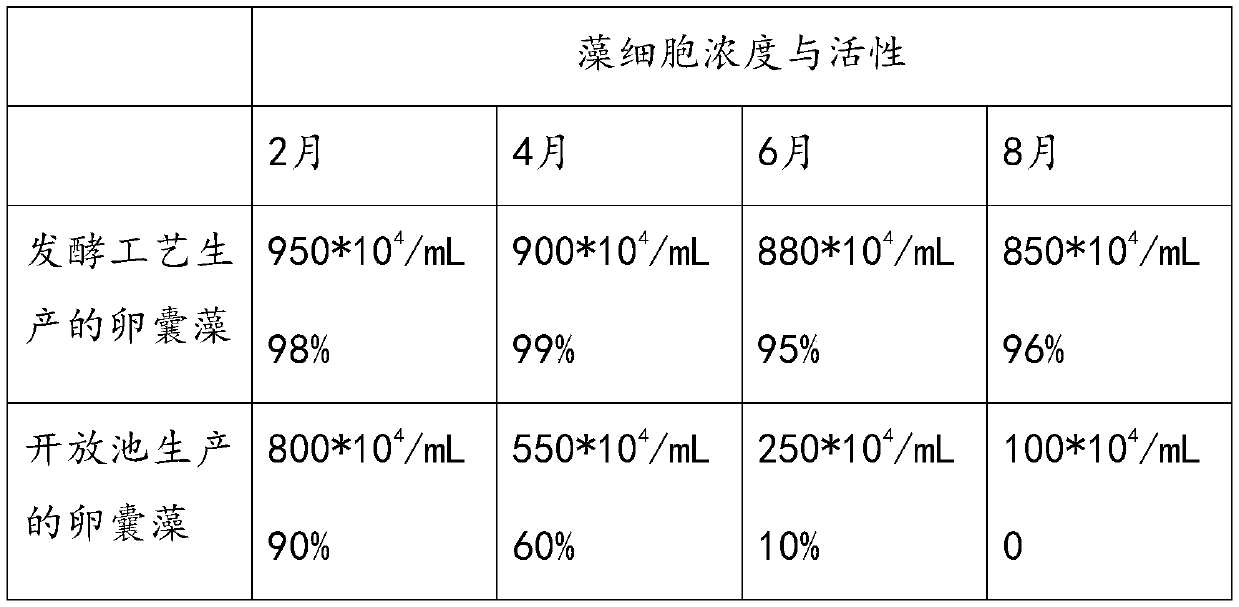

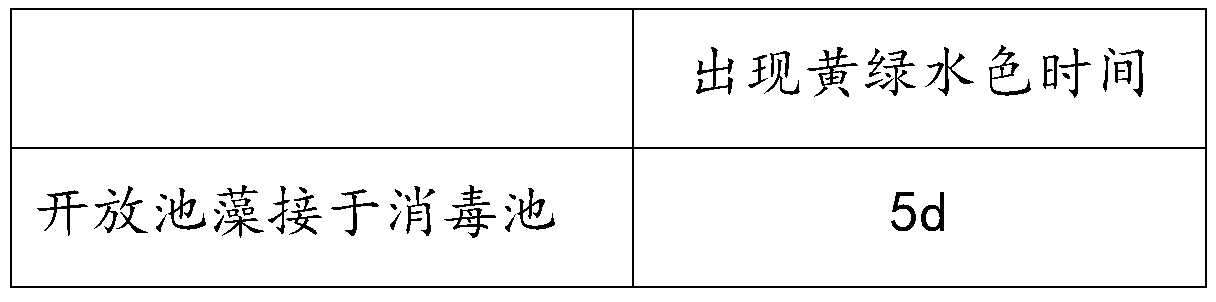

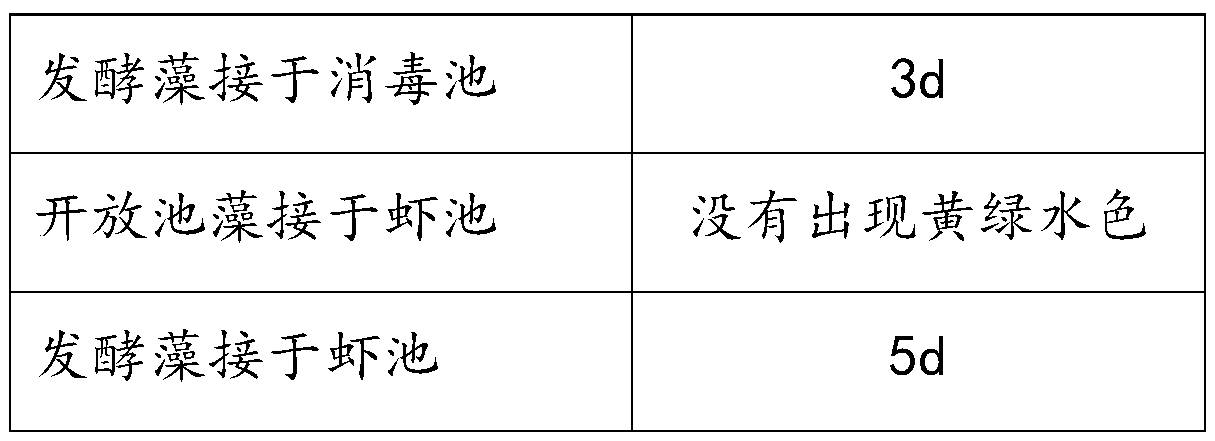

A cultivation process and technology of oocysts, which are applied in the field of aquaculture water quality control and water environment management, can solve the problems of inapplicable expansion stage, insufficient stability of oocyst algal phase, and easy pollution, so as to shorten the time of cultivation and expansion , not easy to aging and anti-algae, strong adaptability to algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, oocysts adopt ultraviolet radiation mutagenesis method, specifically:

[0032] a. Add sodium acetate to Zhanshui 107-13 medium until the concentration reaches 10g / L, inoculate oocysts, and dilute to 10 3 -10 4 Cells / mL, in the ultra-clean bench, place the algae liquid in a large petri dish with a diameter of 20cm, the thickness of the algae liquid does not exceed 0.5cm, and treat it with 8W UVB at a height of 15-20cm for 30min.

[0033] The treated algae liquid was inoculated into the solid Zhanshui 107-13 plate containing 10g / L NaAc, and the normally growing oocyst algae strains were screened out.

[0034] Then the above-mentioned oocyst algae strains are activated, and the above-mentioned obtained algae strains are inoculated into the sterilization reactor for ventilation and light cultivation, the light intensity is 500-700Lx, the ventilation volume is 0.2vvm, and the cultivation time is 4d, until the concentration of the oocyst algae seed...

Embodiment 2

[0038] In the present embodiment, oocysts adopt the ultraviolet radiation mutagenesis method described in Example 1, and then 310*10 4 Oocyst algae seed solution at a concentration of 100L / mL was inoculated into a 100L fermenter for heterotrophic culture, and the initial inoculated seed amount was 10%, accounting for the mass ratio of the medium.

[0039] The medium in the fermenter includes the following concentration components: 3g / L sodium acetate, 0.5g / L potassium nitrate, 0.08g / L potassium dihydrogen phosphate, 0.08g / L ferric chloride, VB1: 0.003g / L, VB12: 0.0002g / L.

[0040] Fed-batch fermentation, feed nutrient salt on the second day after inoculation, including the following concentration components: sodium acetate 300g / L, potassium nitrate 50g / L, potassium dihydrogen phosphate 8g / L, ferric chloride 8g / L, VB1 0.3g / L, VB12 0.02g / L, the amount of the whole feeding nutrient salt is about 30% of the fermented algae liquid.

[0041] Fermentation process parameters: pH in...

Embodiment 3

[0045]In the present embodiment, oocysts adopt the ultraviolet radiation mutagenesis method described in Example 1, and then 350*10 4 Oocyst algae seed solution at a concentration of / mL was inoculated into a 100L fermenter for heterotrophic culture, and the initial inoculated seed amount was 8%, accounting for the mass ratio of the medium.

[0046] The medium in the fermenter includes the following concentration components: 2.2g / L sodium acetate, 0.4g / L potassium nitrate, 0.05g / L potassium dihydrogen phosphate, 0.06g / L ferric chloride, VB1: 0.002g / L, VB12 : 0.00015g / L.

[0047] Fed-batch fermentation, feeding nutrient salt on the second day after inoculation, including the following concentration components: sodium acetate 220g / L, potassium nitrate 40g / L, potassium dihydrogen phosphate 5g / L, ferric chloride 6g / L, VB1-0.15 g / L, VB12-0.015g / L, the amount of the whole feeding nutrient salt is about 35% of the fermented algae liquid.

[0048] Fermentation process parameters: pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com