Method of conducting solid-liquid combined fermentation to prepare baijiu with burnt flavor

A flavor and liquor technology, applied in the field of wine making, can solve the problems of few flavor substances, single taste, high labor intensity, etc., and achieve the effect of increasing main flavor components, adding coke flavor and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

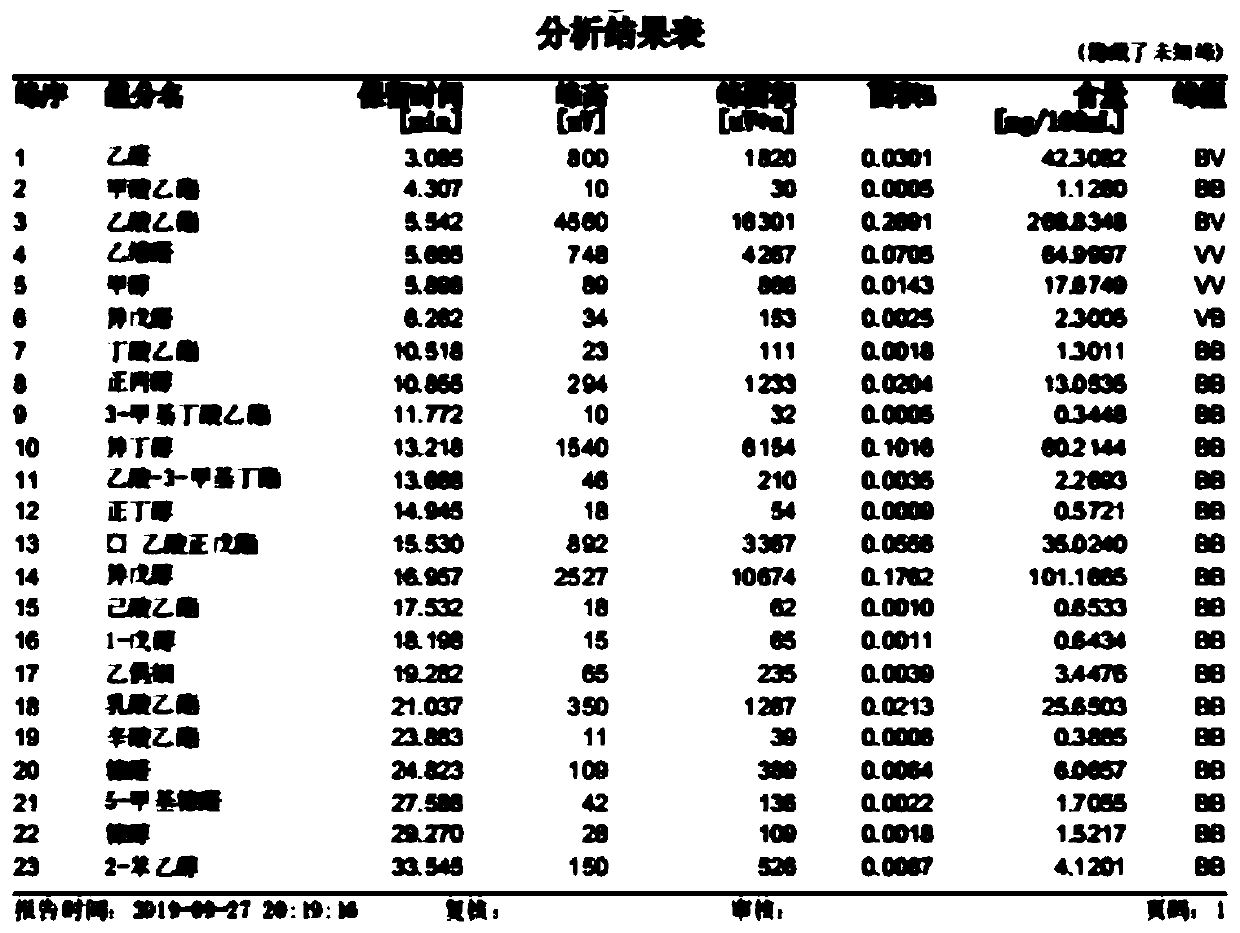

Image

Examples

Embodiment 1

[0035] (1) Pretreatment of peas and barley

[0036] 1) Cleaning of peas and barley: Weigh 1kg of barley and 0.5kg of peas respectively, and rinse them with clean water.

[0037] 2) Drying: Put the washed peas and barley on dry gauze and spread them flat to dry. Flip every half hour for about 2 hours.

[0038] 3) High-temperature roasting: put the dried barley and peas into the roaster, set the roasting temperature to 120°C, and roast for 45 minutes.

[0039] 4) Heating up and roasting: After roasting at high temperature, set the temperature to 150°C for frying, and take it out after 45 minutes of frying.

[0040] 5) Pulverization: grind the fried peas and barley into powder in a pulverizer, and the obtained powder can pass through a 100-mesh sieve.

[0041] 6) Add water: weigh the crushed barley and pea flour, add water 5 times the mass of the barley and pea flour, stir rapidly until there are no lumps and the obtained solution can flow down naturally, to obtain a pea barle...

Embodiment 2

[0069] (1) Pretreatment of peas and barley

[0070] 1) Cleaning of peas and barley: Weigh 1kg of barley and 0.5kg of peas respectively, and rinse them with clean water.

[0071] 2) Drying: Put the soaked peas and barley on dry gauze and spread it flat to dry. Flip every half hour for about 2 hours.

[0072] 3) High-temperature roasting: put the dried barley and peas into the roaster, set the roasting temperature to 120°C, and roast for 45 minutes.

[0073] 4) Heating and roasting: After baking at high temperature, set the temperature to 170°C for frying, and take it out after 30 minutes of frying.

[0074] 5) Pulverization: grind the fried peas and barley into powder in a pulverizer, and the obtained powder can pass through a 100-mesh sieve.

[0075] 6) Add water: weigh the crushed barley and pea flour, add water 4 times the mass of the barley and pea flour, stir quickly until there are no lumps and the resulting solution can flow down naturally, to obtain a pea barley flou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com